LUOYANG DATANG ENERGY TECH CO.,LTD

HDPE Pipe: A Multi-Functional Plastic Pipe

HDPE(High-density polyethylene) Pipe is a highly crystalline, non-polar thermoplastic resin. Its original appearance is milky white, and its thin cross-section is semi-transparent to some extent. The PE material shows excellent chemical resistance and can withstand most household and industrial chemicals. Although certain chemicals, such as corrosive oxidants, aromatic and halogenated hydrocarbons, may chemically corrode it, HDPE still performs well. The polymer is non-hygroscopic and has excellent water vapor resistance, making it ideal for use in packaging. In addition, HDPE has excellent electrical properties, especially its high insulating dielectric strength, making it an ideal choice for wires and cables. The medium to high molecular weight grades of HDPE also have excellent impact resistance, maintaining outstanding performance both at room temperature and at -40 ° F.

1. Introduction of HDPE Pipework

HDPE Pipework, a thermoplastic polyolefin copolymerized from ethylene, has been exploring new application areas since its debut in 1956, though it is not yet mature. This general-purpose plastic has shown broad application potential in both life and industry due to its unique properties, such as a milky white appearance, a semi-transparent thin cross-section, and excellent chemical resistance. Although certain chemicals, such as corrosive oxidants, aromatic hydrocarbons and halogenated hydrocarbons, may chemically corrode it, HDPE can still maintain its excellent performance. In addition, it has the characteristics of being non-hygroscopic, having strong water vapor resistance and excellent electrical properties.

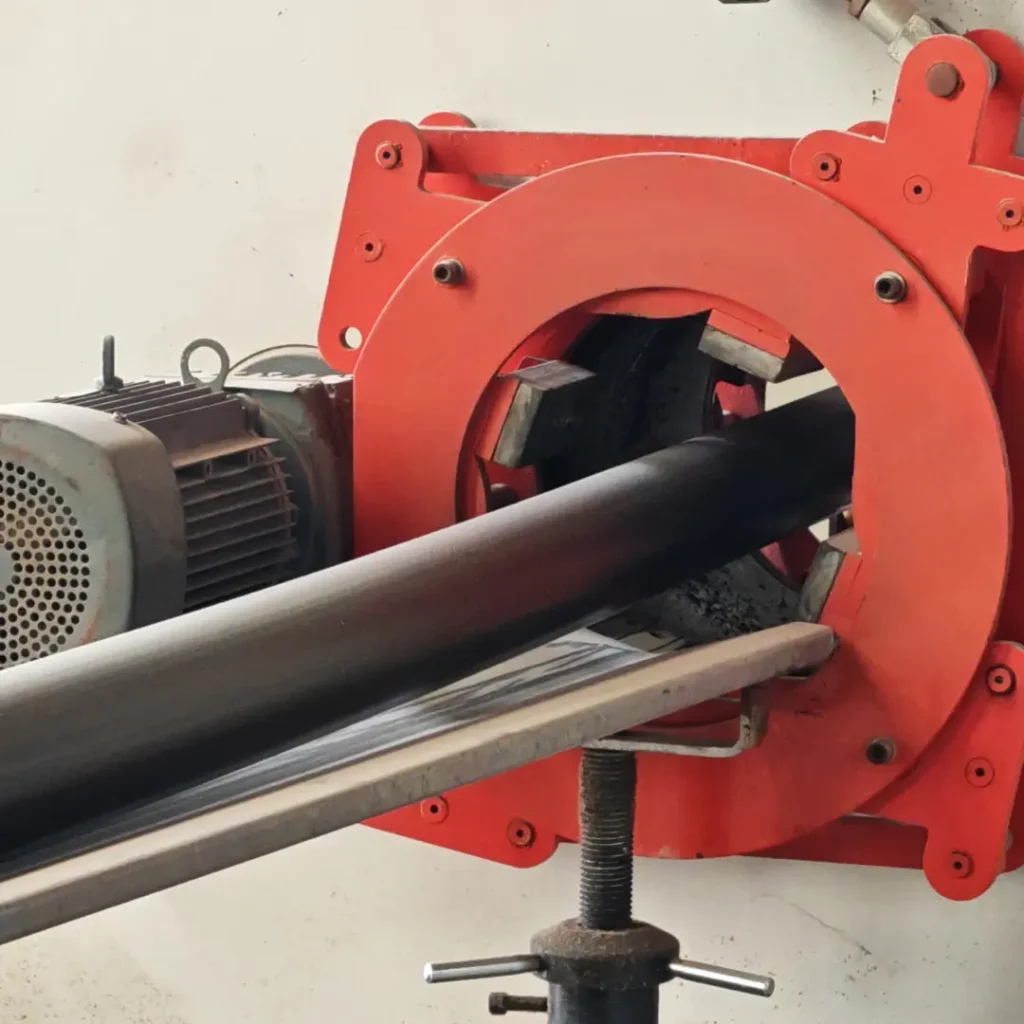

2. Processing and application of HDPE Pipework

PE material can be produced by a variety of processing methods, including sheet extrusion, film extrusion, pipe or profile extrusion, blow molding, injection molding and rotational molding. Among them, HDPE pipes, as alternatives to traditional steel pipes and polyvinyl chloride drinking water pipes, have been widely used in many fields. When manufacturing HDPE pipes, it is often necessary to choose PE resins with high molecular weight and excellent mechanical properties, such as HDPE resin, to ensure the durability and safety of the pipes. In contrast, LDPE resin is not suitable for water pressure pipes due to problems such as low tensile strength, poor pressure resistance, insufficient rigidity, and poor dimensional stability during processing. Nevertheless, LDPE, especially LLDPE resin, is still commonly used in the production of drinking water pipes due to its high hygiene standards. Due to their low melt viscosity, good fluidity and ease of processing, the range of melt index options for LDPE and LLDPE resins is also relatively wide.

3. Properties of HDPE Pipework

Chemical properties

Polyethylene is resistant to a variety of organic solvents and acids, but note that it is not resistant to oxidizing acids such as nitric acid. In an oxidizing environment, polyethylene undergoes oxidation reactions.

Physical properties

Polyethylene is transparent in its film state, however, when it is in bulk, the presence of a large number of crystals inside causes intense light scattering, making it opaque. The degree of crystallization of polyethylene is closely related to the number of its branched chains; the more branched chains there are, the more difficult it is to crystallize. At the same time, the melting temperature of polyethylene crystals is also affected by the number of branches. The melting temperature ranges from 90 ° C to 130 ° C, and the more branches there are, the lower the melting temperature. In addition, polyethylene single crystals can be prepared by dissolving high-density polyethylene in xylene in an environment above 130 ° C.

4. Development of HDPE Water Supply Pipes

With the evolution of water supply and drainage piping systems, plastic pipes have gradually replaced traditional pipes such as cast iron pipes and galvanized steel pipes to become the mainstream in the market. Plastic pipes have gained widespread favor in pipeline engineering thanks to their significant advantages such as light weight, corrosion resistance, low resistance, energy efficiency, easy installation and cost-effectiveness. In addition, the vigorous development of the petrochemical industry and the continuous progress of plastic manufacturing technology have driven the rapid growth of plastic pipe production and the increasing diversity of varieties.

HDPE pipes, after PVC-U water supply pipes, have become the second most consumed type of plastic pipe in the world. In the water supply sector, medium and high-density polyethylene pipes of grades PE80 and PE100 are preferred, while PE63 is gradually being phased out. It is particularly worth noting that PE100 piping systems are growing rapidly in water delivery and are expected to grow by more than 10 percent over the next five years.

In the European market, the application and development of HDPE pipes have been particularly prominent, gradually replacing the position of PVC-U pipes to become the mainstream of local consumption. Meanwhile, the use of HDPE pipes is also expanding in other parts of the world.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe and Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net