LUOYANG DATANG ENERGY TECH CO.,LTD

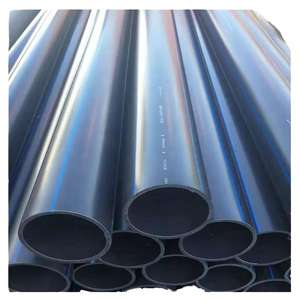

High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

PRODUCT PARAMETERS

Description

Introduction of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

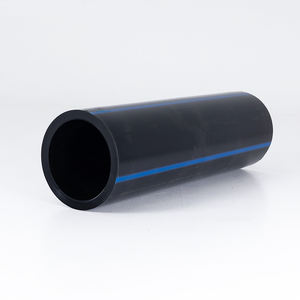

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage)

Specifications of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

High Density Polyethylene tubes, called HDPE pipes, handle water system and drain effectively. These pipes resist deterioration and chemicals well. They sustain extreme environments without rusting or degrading. HDPE pipelines are light-weight. This makes transport and installment less complex. Workers handle them easily. The material is adaptable. It bends without damaging. This adaptability aids in uneven surfaces. Ground activities trigger much less damage.

These pipes are available in various dimensions. Sizes usually range from 20 millimeters to 1200 millimeters. Stress ratings vary. Common classes include PN6, PN10, PN16. These indicate stress capacity in bars. Temperature tolerance is important. HDPE pipelines work from -40 ° C to 60 ° C. They stay reliable in cold or hot problems.

Jointing approaches ensure leak-free systems. Butt fusion and electrofusion welding are basic. These strategies develop solid, long-term seals. Fittings like arm joints and tees attach pipes. They keep system integrity. HDPE pipes meet worldwide criteria. ISO 4427 and ASTM F714 use. These guarantee top quality and performance.

Lengthy life span is an essential advantage. HDPE pipelines last over 50 years. They call for minimal upkeep. No internal scaling happens. Water circulation stays regular. The smooth inner surface area minimizes friction. Pumping prices reduced because of this. These pipes fit potable water systems. They do not infect alcohol consumption water. Drain applications profit as well. HDPE handles sewage and wastewater safely. Ecological stress and anxiety splitting resistance is high. Influence resistance secures against damages during handling. UV stabilizers avoid sunlight destruction. This is essential for revealed installments.

(High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage)

Applications of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

High thickness polyethylene tube HDPE pipes are tough plastic tubes for relocating liquids. People call them PE water pipes too. They work terrific for water supply and drain jobs. These pipelines bring tidy water to homes, manufacturing facilities, and farms. They create the major lines in city water systems and smaller sized lines in towns. Their merged joints develop a solid seal. This quits leakages much better than old pipes. Leakages drainage and cash. These pipes manage treated alcohol consumption water securely.

HDPE pipes also handle wastewater efficiently. They carry sewage away from buildings to therapy plants. They take care of rainwater runoff in tornado drains pipes. Factories use them for moving industrial wastewater and chemicals. The plastic withstands corrosion and chemical damage very well. This makes them last a lot longer than steel pipes underground. They do not rot or get consumed by microbes easily.

The material toughness provides big benefits. HDPE pipelines are really flexible. They flex without breaking. This aids in earthquake locations or uneven ground. They survive ground motion much better than stiff pipes. Their smooth inside surface maintains water moving quickly. This reduces friction and saves pumping power with time. They do not develop much range or sludge inside.

Installation is usually less complicated and less costly. Long pipeline lengths mean less joints needed. Workers can fuse sections with each other rapidly onsite. This produces really dependable, leak-free connections. The pipelines are light contrasted to concrete or metal. This makes them easier to carry and manage. They function well for trenchless techniques like directional drilling. This creates less surface area disruption.

These pipelines last a very long time, over 50 years. They handle freezing and thawing cycles well. They stand up to scrapes and wear from rocks or sand in the ground. This longevity suggests reduced repair service and substitute prices later. They are a clever choice for trustworthy water and wastewater systems.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

What makes HDPE pipe better than metal pipes?

HDPE pipe resists rust and corrosion completely. Metal pipes often rust over time. HDPE handles harsh chemicals in soil much better. It stays strong for decades without degrading. Metal pipes weaken faster. HDPE is lighter too. This makes transport and handling much easier. Installation costs are lower.

Can HDPE pipe bend during installation?

Yes, HDPE pipe is very flexible. You can bend it within its bending radius. This avoids needing extra fittings at slight turns. It saves time and reduces potential leak points. You lay it faster in trenches. The flexibility also helps it handle ground movement well. It won’t crack like rigid pipes.

What fluids can HDPE pipe carry?

HDPE pipe safely carries drinking water. It meets strict health standards. It also handles wastewater, sewage, and industrial drainage. It resists many chemicals. You use it for slurries and mining fluids too. It works for compressed air lines. It handles temperatures from very cold winter conditions to hot summer heat safely.

How long does HDPE pipe last?

HDPE pipe lasts an extremely long time. Its expected service life is over 50 years. It withstands environmental stress cracking very well. It doesn’t corrode or tuberculate inside. Flow capacity stays high over decades. Properly installed, it provides reliable service for generations. It outlasts many other pipe materials.

How much pressure can HDPE pipe handle?

HDPE pipe handles high pressure. Its pressure rating depends on the SDR number. Thicker pipe walls handle higher pressure. Common grades manage pressures from 80 PSI up to 200 PSI or more. It handles surges and water hammer events effectively. Always choose the right SDR for your system’s operating pressure.

(High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage)

REQUEST A QUOTE

RELATED PRODUCTS

Hdpe Water Pipe s 3 Inch 63mm 2.5 Inch High Density 1.5Inch Poly Pe Fitting Pipe Irrigation Pipe

Factory High Density Polyethylene Petutup Hujung Tuberia Hdpe Pipe 90mm Irrigation Coiled 1 Inch Drain Poly Pipe

Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

1000mm Large Diameter Plastic Tube Hdpe Water Drain Pipe

High-Density Polyethylene (PE) Black Pipe for Gas Line Use

Irrigation & Plumbing Polyethylene Pipe Fittings

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677