LUOYANG DATANG ENERGY TECH CO.,LTD

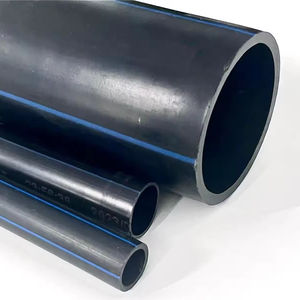

160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine

PRODUCT PARAMETERS

Description

Introduction of 160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine

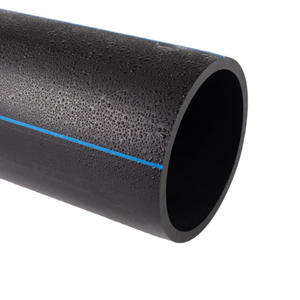

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of 160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine)

Specifications of 160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine

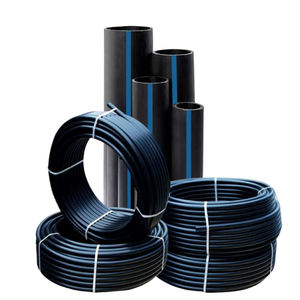

These pipes measure 160mm and 200mm in diameter. They are made from HDPE plastic. HDPE means high-density polyethylene. This product is really solid. It resists chemicals well. It doesn’t rust like metal pipelines. These pipes function great for relocating water. They are perfect for water systems. Farmers use them for watering too. The pipelines handle water circulation efficiently. They decrease rubbing loss inside the pipe.

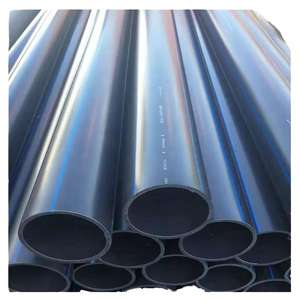

The pipes come in basic stress ratings. Usual ratings are PN6 and PN10. PN6 takes care of pressures approximately 6 bar. PN10 manages up to 10 bar. Select the ranking based upon your job requires. Greater stress needs a higher PN rating. The pipes are versatile. They handle ground movement. This avoids breaks. They last a long time underground. Anticipate many years of reputable service.

The pipelines fulfill worldwide requirements. Search for ISO 4427 qualification. This makes sure high quality and efficiency. They are secure for potable water. They do not include poor preferences or scents. The pipelines are light-weight. This makes them much easier to carry. Setup is quicker than with heavy products.

Signing up with these pipes calls for a special maker. Make use of a polyethylene pipe welding maker. There are two major kinds. Outlet blend makers sign up with smaller sized pipes. Butt blend equipments join bigger pipes like 160mm and 200mm. Butt combination melts the pipeline ends. It presses them with each other. This makes an irreversible, watertight joint. The joint is as solid as the pipeline itself. The device heats the ends to the ideal temperature level. It manages the home heating time. It controls the fusion stress. Appropriate settings are vital. Follow the maker directions precisely.

Excellent welding needs a tidy pipe end. Cut the pipe squarely. Remove any dust or grease. Scrape off the external oxidized layer. The machine should be correctly kept. Routine checks are essential. Educated drivers get the very best results. Appropriately welded HDPE systems are extremely reputable. They require little upkeep later on. This saves time and money. The welding machine is a crucial investment for HDPE projects.

(160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine)

Applications of 160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine

These HDPE pipes determine 160mm and 200mm in size. They are commonly used for relocating water. One significant usage is supplying clean alcohol consumption water to communities and cities. The pipes carry water from treatment plants to homes and companies. They are additionally necessary for ranch irrigation systems. These pipelines effectively provide water across fields for crops. Farmers rely upon them for drip irrigation and sprinkler systems.

HDPE means high-density polyethylene. This product uses important benefits. It is really solid and stands up to fracturing well. HDPE pipes do not corrosion or wear away like steel pipelines can. Chemicals in dirt or water do not damage them. This makes the pipes last a very long time. They deal with high water pressure securely. Their smooth inside surface maintains water flowing openly. This minimizes energy prices for pumping water over distance.

Installing these big pipelines requires strong, long-term joints. This is where the polyethylene pipe welding equipment is crucial. The device heats completions of the HDPE pipeline areas. It melts the material somewhat. Then it presses the melted ends with each other firmly. As the plastic cools, it bonds right into one solid item. This creates a joint as solid as the pipeline itself. The welded connection is entirely water tight. It protects against leakages efficiently. This welding method is the requirement for signing up with HDPE pipes. It ensures reliable efficiency for water and irrigation projects.

The welding devices are developed for large size pipes like 160mm and 200mm. They use accurate temperature level control. Regular stress is applied throughout the joining process. Operators require proper training. Proper welding procedures are critical for system honesty. Utilizing the ideal machine warranties secure links. These links stand up to ground motion and hefty loads. They maintain system performance over years. HDPE pipelines and professional welding are vital for contemporary water framework.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of 160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine

Here are 5 FAQs for a 160mm/200mm HDPE Pipe Welding Machine:

1. Does this machine weld both 160mm and 200mm HDPE pipes?

Yes. The machine handles both sizes. It comes with the right fittings. You adjust the clamping pressure. You set the heater plate temperature correctly. This covers common pipe diameters for water and irrigation projects.

2. How do I weld pipes using this machine?

First, cut the pipe ends square and clean them. Second, clamp the pipe sections securely in the machine. Third, insert the heater plate between the pipe ends. Fourth, apply the correct pressure and heating time. Fifth, remove the heater plate quickly. Sixth, push the molten pipe ends together. Hold them under pressure. Let them cool completely. This makes a strong, leak-free joint.

3. How long does a weld take?

Cutting and cleaning take minutes. The actual heating and joining process takes about 10-20 minutes. Cooling takes much longer. Cooling needs 1-2 hours minimum. Never move the pipe before cooling finishes. Total time depends on pipe wall thickness and conditions.

4. What maintenance does the machine need?

Keep the heater plate very clean. Wipe off melted plastic after every weld. Check the hydraulic oil level regularly. Look for leaks. Inspect the heating elements. Replace worn Teflon sheets on the heater plate. Lubricate moving parts as the manual says. Store the machine in a dry place.

5. What safety features are important?

Protective guards around the heater plate are essential. They prevent burns. The machine needs stable voltage supply protection. Overheating cutoffs are crucial. Wear thick heat-resistant gloves. Wear safety glasses always. Never touch the hot plate or molten pipe. Ensure good workshop ventilation.

(160mm 200mm HDPE Pipe Water Supply Agriculture Irrigation Polyethylene Pipe Welding Machine)

REQUEST A QUOTE

RELATED PRODUCTS

355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes

OEM High Quality Hot BS Standard HDPE White Color Flexible Electrical Conduit High-Density Polyethylene Plastic Tubes

High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

3LPE Anti-Corrosion Spiral Pipe 3PE Urban Water Supply Pipeline With ASTM SABS Certificates For Drill Pipe And Structure Use

High Density Polyethylene Pipe HDPE PE100 Large Diameter Hdpe Tubes for Water Supply 25mm 250mm 500mm 1000mm

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677