LUOYANG DATANG ENERGY TECH CO.,LTD

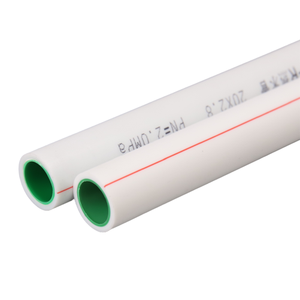

High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe

PRODUCT PARAMETERS

Description

Introduction of High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe

PPR pipe (full name Polypropylene Random Copolymer Pipe, is a high-performance plastic pipe made of high-quality random copolymer polypropylene raw materials. Due to its high temperature resistance, pressure resistance, environmental protection and non-toxicity, it is widely used in building hot and cold water systems, HVAC engineering, drinking water transportation and industrial fluid transmission, and is an ideal substitute for traditional metal pipes.

Characteristics and Features of High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe

High temperature and high pressure resistance

Long-term working temperature can reach 70°C, short-term high temperature resistance to 95°C, excellent pressure bearing performance (common pressure level PN20, PN25).

Environmental protection and health

The raw materials are pure and non-toxic, meet drinking water standards (such as FDA, EN ISO and other certifications), do not breed bacteria, and ensure the safety of water quality.

Corrosion and anti-scaling

Acid and alkali resistance, strong chemical corrosion resistance, smooth inner wall, not easy to scale, long-term use of stable flow.

Hot melt connection, strong sealing

Adopting hot melt socket technology, there is no risk of leakage at the connection, and the integrated structure improves system reliability.

Lightweight and easy to construct

The weight is only 1/8 of that of metal pipes, which is convenient for transportation and installation, reducing labor costs.

Long life and low maintenance

The designed service life is more than 50 years, maintenance-free, and the overall cost is low.

Energy-saving and heat preservation

The thermal conductivity is low (only 1/200 of metal pipes), which reduces heat loss and is suitable for hot water systems.

(High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe)

Specifications of High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe

This High Openness Strike Molding Quality PP Random Copolymer provides superb performance. It works flawlessly for food movie applications. It likewise meets criteria for PPR pipeline production. The product makes certain outstanding clarity. This makes it suitable for transparent product packaging. The product is safe for direct food contact. It complies with stringent international food safety policies.

Key requirements define its high quality. The melt circulation price commonly varies in between 2.0 to 4.0 g/10min. This sustains reliable impact molding processes. Density actions around 0.905 g/cm SIX. The product provides high tensile toughness. Expect values over 30 MPa. It maintains great effect resistance. This avoids brittleness at lower temperatures.

Heat resistance is reputable. The melting factor hugs 140 ° C. The material holds up against hot loading treatments. It withstands contortion under warm anxiety. Optical properties transcend. Haze levels procedure under 10%. Light transmission goes beyond 90%. This clearness showcases item materials efficiently.

Chemical resistance is strong. The polymer handles common food substances. It resists acids, oils, and alcohols. Handling security corresponds. It moves smoothly during extrusion. This makes certain uniform film density. It also maintains dimensional precision in pipelines. The material is moisture resistant. Drying prior to refining decreases potential concerns. It creates reduced odor and taste. This preserves foodstuff honesty.

Certifications consist of FDA and EU food contact compliance. It passes migration tests for security. The material is available in all-natural transparent form. Additives can be tailored for specific needs. This PP copolymer equilibriums openness with resilience. It satisfies demanding manufacturing demands.

(High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe)

Applications of High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe

High Openness Blow Molding Quality PP Random Copolymer Polypropylene is an unique plastic. People likewise call it Food Movie Quality PPR Pipe material. This plastic has superb transparent top quality. It is risk-free for food contact. It is strong and difficult. It takes care of heat and chemicals well.

One vital use is impact molding. Blow molding makes hollow plastic points. This PP material works wonderful for clear bottles and containers. You see these in food and beverage product packaging. It keeps products fresh. It benefits medication containers also. The high clearness allows individuals see the components. This develops confidence.

An additional significant usage is PPR pipes. PPR pipes are for water supply. They bring cold and hot water. This PP product takes care of heats. It does not break down conveniently. It stays secure for drinking water. It includes no poor taste or scent. The pipelines resist corrosion and deterioration.

This PP product is used in food films. These films cover and safeguard food. They are clear so purchasers see the product. They block wetness and air. This keeps food fresh longer. They are safe for direct food touch.

The pipelines last a very long time. They take care of high pressure. They operate in homes and manufacturing facilities. They are very easy to mount. They conserve repair service costs.

The strike molding quality procedures conveniently. Factories like it. It accelerates production. It cuts waste. It decreases prices.

This PP product remains in lots of day-to-day products. It remains in cooking area containers. It is in water pipes. It remains in supermarket food wraps. It is reliable for these work.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe

What is this product used for? This high transparency PP random copolymer is designed for blow molding applications. It creates clear bottles, jars, and containers. It also works for food packaging films. Additionally, it serves in PPR pipes for plumbing systems carrying drinking water.

Why choose this specific grade? The material offers exceptional clarity. This makes products visually appealing. It has strong impact resistance. The copolymer structure ensures durability. It meets strict food safety standards.

Is it safe for food contact? Yes. This PP grade complies with FDA and EU regulations. It contains no harmful additives. It’s suitable for direct food packaging. It’s ideal for water pipes too.

What are its main properties? Key features include high transparency like glass. It resists chemicals well. It handles temperature changes reliably. Processing is easy with standard equipment. It maintains strength under pressure.

How is it processed? Use standard blow molding machines. Keep temperatures between 200-230°C. For films, extrusion works best. Preheat material properly. Control cooling rates for clarity. Dry pellets before processing to prevent defects.

(High Transparency Blow Molding Grade PP Random Copolymer Polypropylene Food Film Grade PPR Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

Whole PPR Material Polypropylene Industrial ppr Pipe

Random Copolymer Polypropylene Plastic Raw Material PP Pellets Pipe Grade

Customized Plastic Big Pipe Clear PP Tube Polypropylene

Hot Factory Customized ABS PE PP Pvc Clear Tubes Plastic Extrusion

Whole Plastic Tubes High Pressure Ppr Pipes Plumbing Pipe 20-32mm PprTubes

Green PPR Water Tube PN20 20-160mm PPR Plumbing Pipes Pure Plastic PPR Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677