LUOYANG DATANG ENERGY TECH CO.,LTD

High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications

PRODUCT PARAMETERS

Description

Introduction of High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications

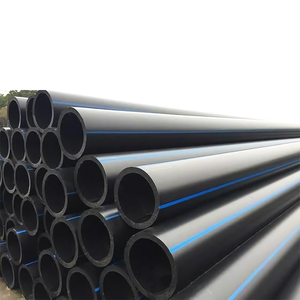

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications)

Specifications of High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications

Here’s the product content for HDPE pipes at 1.6 MPa:

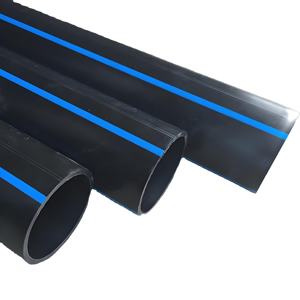

These HDPE water pipes are developed for requiring 1.6 MPa stress systems. This pressure rating equates to 16 bar. It suggests the pipelines reliably deal with high inner water stress. The pipes use high-density polyethylene product. HDPE is difficult and flexible. Its firmly loaded particles give excellent toughness. The product withstands numerous chemicals. This consists of acids and bases. HDPE also holds up against effects well. It does not crack conveniently. The pipes will not wear away or corrosion. This makes them excellent for water. They last a long time underground. HDPE pipes are lightweight. This simplifies handling and setup. Workers conserve effort and time. Usual dimensions consist of 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 75mm, 90mm, 110mm, and 160mm sizes. Larger dimensions are available. The conventional shade is black. A blue red stripe runs along the pipeline size. This stripe identifies safe and clean water usage. The pipes work in a large temperature range. They carry out from -40 ° C to 60 ° C. This covers most climates. The smooth inner surface area lessens friction. Water circulation remains reliable. Power costs for pumping are lower. Drip risks are significantly minimized. The joints fuse with each other completely. This produces a continual, covered system. Installment techniques include butt blend and electrofusion. Both produce solid, long-term connections. These pipelines are mainly for underground usage. They move drinkable water safely. Local water system networks utilize them. Commercial water transfer systems depend on them. Watering projects gain from them.

(High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications)

Applications of High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications

HDPE pipelines rated for 1.6 MPa deal with requiring water pressure scenarios well. They are strong and reliable. This pressure rating amounts to around 16 bar or 230 PSI. These pipes fit several essential applications where high pressure is normal.

Community water networks often utilize these pipes. They lug water under high pressure from treatment plants to tank and through circulation mains. Their durability withstands splitting and leakages over long distances. This guarantees consistent water distribution to homes and companies.

Industrial centers require robust piping. 1.6 MPa HDPE pipelines function well inside manufacturing facilities and plants. They transport process water, cooling water, and various other fluids reliably. Their resistance to rust and chemicals protects against system failings. This reduces pricey downtime and upkeep.

Mining procedures put pipelines under extreme tension. These high-pressure HDPE pipelines transport slurry, tailings, and process water dependably. They hold up against abrasion from solids in the flow. Their versatility assists them handle ground motion usual in mines. This longevity is important for safety and productivity.

Large irrigation systems rely on reputable high-pressure pipes. 1.6 MPa HDPE pipes provide water successfully across vast agricultural locations. They handle the stress needed for lawn sprinklers and center pivots. Their smooth internal surface area decreases friction loss. This saves power and improves water circulation.

Firefighting systems call for pipes that won’t fall short under stress. These HDPE pipelines serve well as mains and feeders for fire hydrant networks. They maintain architectural stability during high-flow fire events. This dependability is essential for emergency situation response.

Facilities tasks like passages and bridges often define these pipes. They supply a leak-free remedy for pressurized water conduits in challenging environments. Their long life span minimizes replacement costs dramatically.

The material itself is inert. HDPE does not communicate with water. It maintains alcohol consumption water secure and clean. No dangerous substances seep into the water supply. This is necessary for public health and wellness.

Setup advantages are clear. These pipes are lighter than steel options. Workers take care of and join them much more conveniently. Fusion welding develops smooth, monolithic joints. No leaks happen at link factors. This conserves time and labor during construction.

Lasting efficiency is excellent. HDPE stands up to environmental anxiety splitting. It does not rust or tuberculate like steel pipelines. Circulation capacity stays high over decades. Upkeep demands are very little. This lowers the total cost of possession substantially.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications

What pressure can 1.6MPa HDPE pipes handle?

1.6MPa HDPE pipes are designed for a maximum working pressure of 16 bar at 20°C. This pressure rating means they reliably carry water under high pressure. Always check the specific pipe’s rating before installation.

Does temperature affect HDPE pipe pressure?

Yes, temperature matters. HDPE pipes hold less pressure as water temperature rises. At 20°C, 1.6MPa pipe handles 16 bar. At 40°C, its maximum pressure drops significantly. Consult the manufacturer’s tables for exact figures at different temperatures.

What chemicals can 1.6MPa HDPE pipe resist?

HDPE pipe resists many chemicals well. It handles most acids, alkalis, and salts found in water systems safely. It also resists corrosion from aggressive soils. HDPE is not good for strong oxidizing acids or some hydrocarbons. Check chemical compatibility charts first.

How is installing HDPE pipe different from metal pipe?

HDPE pipe installs differently than metal. It is much lighter. Workers move and handle it easily. You join sections using heat fusion. This creates seamless, leak-proof joints. HDPE needs proper support. Avoid sharp bends. It expands and contracts more with temperature changes than metal.

How long does 1.6MPa HDPE pipe last?

Properly installed HDPE pipe lasts over 50 years. Its resistance to corrosion and chemical attack gives it a very long service life. Underground installations avoid UV degradation. Correct pressure and temperature use are key for maximum lifespan.

(High-Density Polyethylene (HDPE) Water Pipes for 1.6MPa Applications)

REQUEST A QUOTE

RELATED PRODUCTS

1000mm Large Diameter Plastic Tube Hdpe Water Drain Pipe

Hdpe Water Pipe 3 6 10 12 Inch 32mm 200mm 1000mm Diameter 16 Bar Polyethylene s List Per Meter s

High Density Polyethylene HDPE Pipe 4 Inch 5 Inch 6 Inch PE100 Water Pipe Corrosion Resistant High Pressure Non-Toxic Anti-UV

High Density HDPE PE100 Large Diameter Polyethylene Pipe For Water Supply

PE100 Black HDPE Pipe Grade Resin Granules Polyethylene Raw Material High Density Polyethylene Virgin HDPE 100 PEHD

High-Density PE Polyethylene Pipe Large Diameter 110mm-800mm Polyethylene Bellows Drainage

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677