LUOYANG DATANG ENERGY TECH CO.,LTD

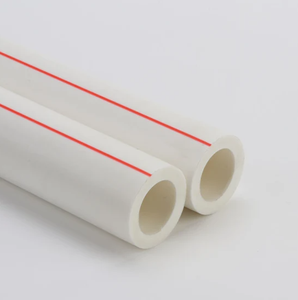

Plastic PPH IPS Best Crew Pipe

PRODUCT PARAMETERS

Description

Introduction of Plastic PPH IPS Best Crew Pipe

PPR pipe (full name Polypropylene Random Copolymer Pipe, is a high-performance plastic pipe made of high-quality random copolymer polypropylene raw materials. Due to its high temperature resistance, pressure resistance, environmental protection and non-toxicity, it is widely used in building hot and cold water systems, HVAC engineering, drinking water transportation and industrial fluid transmission, and is an ideal substitute for traditional metal pipes.

Characteristics and Features of Plastic PPH IPS Best Crew Pipe

High temperature and high pressure resistance

Long-term working temperature can reach 70°C, short-term high temperature resistance to 95°C, excellent pressure bearing performance (common pressure level PN20, PN25).

Environmental protection and health

The raw materials are pure and non-toxic, meet drinking water standards (such as FDA, EN ISO and other certifications), do not breed bacteria, and ensure the safety of water quality.

Corrosion and anti-scaling

Acid and alkali resistance, strong chemical corrosion resistance, smooth inner wall, not easy to scale, long-term use of stable flow.

Hot melt connection, strong sealing

Adopting hot melt socket technology, there is no risk of leakage at the connection, and the integrated structure improves system reliability.

Lightweight and easy to construct

The weight is only 1/8 of that of metal pipes, which is convenient for transportation and installation, reducing labor costs.

Long life and low maintenance

The designed service life is more than 50 years, maintenance-free, and the overall cost is low.

Energy-saving and heat preservation

The thermal conductivity is low (only 1/200 of metal pipes), which reduces heat loss and is suitable for hot water systems.

(Plastic PPH IPS Best Crew Pipe)

Specifications of Plastic PPH IPS Best Crew Pipe

The Plastic PPH IPS Ideal Crew Pipeline offers strong performance for commercial systems. This pipe uses polypropylene homopolymer material. PPH plastic manages hard chemicals well. It withstands acids and antacid properly. This pipeline suits demanding environments. Corrosion won’t harm it easily. Long life span is an essential benefit.

Various dimensions are offered. Criterion diameters range from half an inch to twenty-four inches. Wall thickness differs by pressure requirements. Stress rankings cover PN10 and PN16 courses. PN10 takes care of lower pressure systems. PN16 manages greater pressure demands. Select the score matching your task demands.

Temperature level tolerance is very important. This pipeline functions from minus twenty levels Celsius to ninety levels Celsius. Warm fluids won’t warp it. Cold problems won’t make it fragile. Consistent performance throughout temperatures is trusted.

Installation is straightforward. The pipe uses IPS links. IPS implies iron pipeline size threading. Threaded installations sign up with areas securely. Assembly needs standard tools. Upkeep remains simple also. Fewer leakages happen with appropriate threading.

Applications include chemical transport. Water therapy plants use these pipes. Industrial processing lines take advantage of them. HVAC systems utilize PPH pipelines for coolant. They relocate aggressive liquids safely. No steel corrosion concerns happen.

Trick benefits include lightweight style. Moving and handling is simpler. Prices stay less than steel choices. Smooth inner wall surfaces lower circulation resistance. Power financial savings result from this. Ecological resistance is exceptional. Sunlight and weather condition don’t deteriorate PPH material swiftly.

(Plastic PPH IPS Best Crew Pipe)

Applications of Plastic PPH IPS Best Crew Pipe

Plastic PPH IPS Finest Crew Pipe provides exceptional services for numerous requiring commercial work. This pipeline handles tough chemicals effectively. It stands up to deterioration from acids, alkalis, and various solvents. This makes it excellent for chemical processing plants. Factories moving aggressive liquids rely upon it.

Warm water and steam systems likewise profit substantially. PPH pipe stands up to high temperatures accurately. It maintains its stamina also under warmth stress and anxiety. Warm water circulation in manufacturing facilities uses it commonly. Industrial washings depend upon its warm tolerance.

Relocating rough materials is an additional key usage. Slurries and mining waste circulation effectively with PPH pipelines. The smooth inside surface area reduces friction and wear. Mining operations mount it for slurry transport. Nuclear power plant use it for fly ash handling.

Clean water systems require long lasting piping as well. PPH pipeline is perfect for commercial water treatment. It takes care of both raw water and cured water safely. Wastewater plants utilize it thoroughly. It does not corrode or deteriorate in these wet problems.

Food and drink production calls for rigorous hygiene. PPH pipe satisfies these high standards easily. It doesn’t sustain microbial development. Its smooth finish cleans up rapidly. Dairy products plants and breweries install it for product lines.

Setup is simple and saves time. The IPS Best Team joint system attaches pipes quickly. It creates strong, watertight seals accurately. Employees appreciate the straightforward push-fit approach. This cuts labor prices significantly on big projects.

PPH pipeline lasts a long time. It exceeds steel pipelines in harsh atmospheres. Upkeep requirements are marginal. Replacement prices drop sharply. Operations run smoother with less downtime.

Price savings are clear over the pipe’s life time. First cost is competitive. Installation is less costly and much faster. Lengthy service life suggests less substitutes. Reduced maintenance keeps continuous costs down. Power costs may lower because of far better circulation performance.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Plastic PPH IPS Best Crew Pipe

Plastic PPH IPS Best Crew Pipe – FAQs

What is PPH IPS Best Crew Pipe?

PPH IPS Best Crew Pipe is a plastic pipe system. It uses polypropylene homopolymer material. This material is tough. It resists chemicals well. The pipe handles high temperatures. It works for industrial plumbing. The IPS part means iron pipe size. That ensures standard fittings fit.

Where is this pipe typically used?

Use it in factories first. It moves aggressive chemicals safely. Water treatment plants need it too. It carries hot water without warping. Builders pick it for corrosive environments. Avoid using it for drinking water systems. Stick to industrial settings.

Why pick PPH over other plastics?

PPH lasts longer than PVC or PP. It won’t crack under stress. Heat doesn’t soften it easily. Chemicals like acids don’t eat through it. Maintenance costs stay low. You save money over time. It’s reliable for heavy-duty jobs.

How is the pipe installed?

Cut the pipe clean first. Use a saw for plastic. Deburr the edges smooth. Heat the socket and pipe end with a tool. Join them quickly before cooling. Hold them straight for 30 seconds. Check for no gaps. Let it cool fully before testing.

What maintenance does it need?

Check for leaks monthly. Look at joints especially. Clean the pipe surface with water. Don’t use harsh scrubs. Avoid hitting it with hard objects. Fix small damage fast. Replace sections if cracks appear. No special coatings are needed.

(Plastic PPH IPS Best Crew Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality PPR Plastic Water Supply Tubes Premium Pressure Resistant

Polypropylene Random Copolymer PP Extrusion Sheet Pipe Blow Molding

Best PPR Pipes and Fittings For Industrial Cooling System

32mm 50mm 75mm PN12.5 Plastic Polypropylene PPR Pure Plastic Pipes Hot Cold Water

Polypropylene (PP-R) Pipes for Home Decoration

Wholesale PN16 PN20 PN25 PPR Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677