LUOYANG DATANG ENERGY TECH CO.,LTD

Professional HDPE LDPE PP ABS Pehd Pipe Machine

PRODUCT PARAMETERS

Description

Introduction of Professional HDPE LDPE PP ABS Pehd Pipe Machine

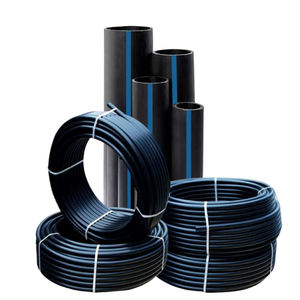

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Professional HDPE LDPE PP ABS Pehd Pipe Machine

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Professional HDPE LDPE PP ABS Pehd Pipe Machine)

Specifications of Professional HDPE LDPE PP ABS Pehd Pipe Machine

This maker makes plastic pipelines from HDPE, LDPE, PP, and ABS materials. It deals with various plastic pellets well. The maker produces pipes dependably for industrial usage. Its outcome ability depends upon the version. Machines commonly make 50 to 500 kgs per hour. The pipe size range is very important. It usually makes pipelines from 16mm approximately 160mm diameter. Wall surface thickness control is exact. You can readjust density settings quickly.

The extrusion screw is a crucial part. Screw sizes range 45mm and 90mm. Screw layout suits certain plastics. Different screws enhance melting and blending. The screw size ratio is vital. Common proportions are 25:1, 28:1, or 33:1. This ensures appropriate plastic circulation. The barrel has heating zones. Usually 4 to 6 areas enable specific temperature level control. Each zone warms separately. Temperature level security is vital for top quality pipelines.

Power requirements are substantial. Key drive motors vary from 15kW to 75kW. This powers the extrusion screw. Complementary drives require power as well. Cooling down systems are essential. Tanks utilize vacuum cleaner or spray cooling. This sets the pipe form swiftly. Pipe haul-off devices draw the pipe steadily. Haul-off rate matches extrusion rate. Cutting devices reduced pipes to establish sizes. Saws are automated.

Control systems take care of whatever. Modern PLC panels are typical. Operators established specifications conveniently. Touchscreens show real-time information. Safety and security functions shield employees. Emergency situation quits are accessible. Guards cover relocating components. The structure is hefty steel. This minimizes resonance throughout procedure. Security makes sure constant pipeline top quality. Makers need a strong structure.

(Professional HDPE LDPE PP ABS Pehd Pipe Machine)

Applications of Professional HDPE LDPE PP ABS Pehd Pipe Machine

This maker makes strong plastic pipelines. These pipelines resolve many troubles. Individuals need pipes for water supply. HDPE pipes work great here. They do not rust. They don’t leakage. They last a very long time. Gas firms make use of HDPE pipes as well. These pipelines are secure for gas lines. They take care of pressure well. They withstand splits. Mining operations need tough pipelines. HDPE pipelines relocate slurry and tailings. They manage abrasion. They do not break easily.

Factories use several chemicals. PP pipelines benefit this. PP resists many acids. PP withstands lots of bases. These pipelines won’t rust. They keep chemicals inside safely. Wastewater treatment plants make use of pipes. ABS pipelines are common here. ABS takes care of dirty water flow. ABS is solid. It does not get breakable. Building tasks need drainage. Abdominal muscle pipelines function well under structures. Abdominal pipelines function well inside wall surfaces. They are light. They are easy to set up.

This machine makes all these pipes. It controls the pipeline size exactly. It regulates the pipe wall surface density exactly. This uniformity issues. Good pipes require regular high quality. The machine makes lengthy pipe sizes. Long pipelines imply fewer joints. Less joints imply fewer leakages. The device deals with different plastics. It makes HDPE pipes. It makes LDPE pipes. It makes PP pipes. It makes ABS pipes. This versatility is useful. Factories can make what customers need. The equipment creates trusted pipes. Trusted pipes make systems function. They save money on repair services. They keep things moving.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Professional HDPE LDPE PP ABS Pehd Pipe Machine

Professional HDPE LDPE PP ABS Pehd Pipe Machine FAQs

What plastics does this machine handle?

This machine processes HDPE, LDPE, PP, ABS, and PEHD materials. It makes pipes from these common thermoplastics. The extruder and screw design handle different melt temperatures. You get flexibility for various pipe projects.

How much pipe can it produce?

Output depends on the machine model and pipe size. Smaller machines might make 50kg per hour. Larger industrial units can exceed 300kg per hour. Pipe diameter and wall thickness affect the speed. Check the specific model’s capacity before buying.

Is setup complicated?

Setup is straightforward for trained operators. Changing dies and calibrating takes time initially. Once configured for a specific pipe size and material, production runs smoothly. Basic training covers essential setup procedures.

Can I control pipe thickness and diameter?

Yes, you control these precisely. The machine adjusts screw speed and haul-off speed. This changes the pipe wall thickness. Changing the extrusion die alters the pipe’s outer diameter. Settings are fine-tuned during production.

Does it support extra features?

Many models offer optional add-ons. You can include automatic cutting for specific lengths. Printers mark the pipe surface. Vacuum sizing tanks ensure perfect roundness. Cooling systems improve production speed. Discuss your exact needs with the supplier.

(Professional HDPE LDPE PP ABS Pehd Pipe Machine)

REQUEST A QUOTE

RELATED PRODUCTS

Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

High Quality Industrial Plastic PVC Tube UPVC Pipe For Water With High Pressure

s Direct Injection Cement Pipe High-Density Polyethylene Corrugated Stainless Steel Pipe

High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction

s High Density Polyethylene Pe100 HDPE Polyethylene Plastic Tube Hdpe Sdr11 Pipe

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677