LUOYANG DATANG ENERGY TECH CO.,LTD

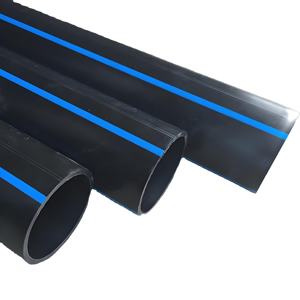

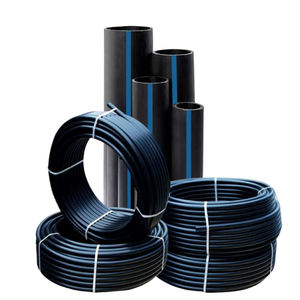

High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

PRODUCT PARAMETERS

Description

Introduction of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s )

Specifications of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

These High-Density Polyethylene (HDPE) pipes deliver solid, reliable water. They are developed tough for high-pressure systems. HDPE material resists deterioration and chemicals quite possibly. This makes them excellent for severe settings. They handle hostile soils and numerous liquids securely. Corrosion and scale build-up inside the pipeline isn’t a problem.

The pipes can be found in conventional dimensions from little sizes like 20mm as much as huge diameters like 1200mm. Stress ratings are plainly marked. Usual scores include PN6, PN10, PN16, and higher. PN16 pipes endure 16 bar stress. Select the ranking matching your system’s maximum operating pressure. SDR values show the pipe wall thickness relative to its diameter. A reduced SDR number means a thicker wall surface. Thicker walls handle higher stress.

Installation is straightforward. HDPE pipelines are surprisingly light-weight contrasted to steel alternatives. This streamlines transport and taking care of on website. They offer great flexibility. You can contour them somewhat within limits during trench laying. This decreases the requirement for added fittings occasionally. Jointing usages trustworthy heat combination strategies. Effectively integrated joints create a leak-free, monolithic system. The joint stamina matches the pipeline strength itself.

These pipes last decades underground. They withstand splitting and environmental anxiety really efficiently. Abrasion resistance is high for sandy conditions. The smooth inner surface keeps water moving successfully. Friction loss is reduced. This conserves pumping energy with time. HDPE won’t support organic growth inside the pipeline. Water quality stays tidy.

Make use of these sturdy pipelines for major water lines, industrial supply networks, watering systems, and slurry transport. They carry out dependably in mining, dredging, and various other demanding applications.

(High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s )

Applications of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

High-density polyethylene pipes provide water under hefty stress. These HDPE tubes are tough. They last a very long time. Their smooth inside surface area assists water circulation easily. This minimizes pumping power costs. Water relocates faster with much less rubbing.

These pipes resist rust and chemical damage totally. Steel pipes often fall short from corrosion. HDPE pipes prevent this issue. They deal with harsh soils and water problems well. This makes them trusted for years. Replacement prices drop dramatically.

Local water systems use these pipelines extensively. They form the foundation for city water pipe. They lug drinking water safely. They additionally benefit firefighting water lines. Stress needs are high in these situations. HDPE manages it accurately.

Industrial centers depend upon these pipes as well. Factories require huge volumes of procedure water. HDPE pipelines provide this consistently. Mining operations utilize them for slurry transportation. Their abrasion resistance is crucial right here. Farms utilize them for watering systems. They stand up to sunlight direct exposure and field conditions.

Energy service providers install these pipes efficiently. They are lighter than old materials like steel or concrete. Handling them is simpler. Workers connect areas swiftly utilizing warmth blend. This creates leak-proof joints. The pipeline turns into one continuous line. Ground movement rarely damages these integrated joints.

Trenchless installment approaches save cash and time. HDPE pipes can be pulled via existing courses. They don’t always require open trenches. This lessens excavating in streets. Website traffic disruption is much less. Fixing landscapes is less complicated. These pipes bend somewhat during installment. They follow curves underground without extra installations. This streamlines the job.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

FAQs for High-Density HDPE Pipe: Durable High-Pressure Water Supply Polyethylene Tube

What makes HDPE pipe strong?

HDPE pipe uses high-density polyethylene plastic. This material is very tough. It resists cracks and breaks well. The pipe handles high water pressure reliably. It doesn’t rust or corrode like metal pipes. This strength comes from the plastic’s molecular structure. It bends slightly without breaking.

How long does HDPE pipe last?

HDPE pipe lasts a very long time. Expect 50 years or more with proper installation. Its resistance to chemicals and corrosion helps. Sunlight damage is minimal. Underground, it withstands soil movements and most chemicals. Proper installation is key for maximum life.

What pressure can HDPE pipe handle?

HDPE pipe handles very high water pressure. The exact rating depends on the pipe’s size and wall thickness. Manufacturers test pipes to specific pressure classes. Always choose the pressure class matching your system’s needs. Common classes handle pressures common in municipal and industrial water supply.

Can HDPE pipe handle chemicals?

Yes, HDPE pipe resists many chemicals. This includes acids, alkalis, and salts. It won’t corrode from inside or outside. This makes it safe for various water types. It’s good for potable water, wastewater, and some industrial fluids. Check chemical compatibility charts for specific aggressive chemicals.

How do you join HDPE pipe sections?

Joining HDPE pipe is reliable. The main methods are heat fusion. Butt fusion melts pipe ends together. Electrofusion uses special fittings with heating elements. Both methods create leak-proof joints. The joint becomes as strong as the pipe itself. Mechanical fittings are also used sometimes.

(High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s )

REQUEST A QUOTE

RELATED PRODUCTS

High Pressure HDPE Pipe for Water Supply Irrigation Agriculture Flexible Underground Drainage Roll-Industrial Construction

Professional HDPE LDPE PP ABS Pehd Pipe Machine

HDPE Flexible Construction Plastic Tubes High Pressure Underground Water Supply Industrial Pressure System Drainage Tubing 6mm

s High Density Polyethylene Pe100 HDPE Polyethylene Plastic Tube Hdpe Sdr11 Pipe

PE Gas Pipe High-Density Polyethylene Plastic Tubes

HDPE 45 Degree PE Elbow High-Density Polyethylene Pipe Fitting For Water Supply

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677