LUOYANG DATANG ENERGY TECH CO.,LTD

Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

PRODUCT PARAMETERS

Description

Introduction of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

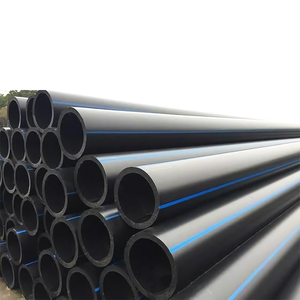

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater)

Specifications of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

These aquatic HDPE plastic dredging pipe floaters sustain undersea pipelines. They maintain sand discharge and digging up pipes secure on the water surface. The drifters are made from high-density polyethylene. This material is extremely challenging. It resists deep sea corrosion well. Sunlight damages is also very little. HDPE drifts last a long period of time in rough sea conditions.

The layout is streamlined. Water streams past conveniently. This lowers drag on the pipeline system. The floaters offer solid buoyancy. They raise heavy pipelines filled with sand and water. Different buoyancy ratings exist. You select based on pipeline dimension and load. Common sizes fit pipes from 6 inches to 24 inches size.

Setup is straightforward. The two-piece clamshell style twists around the pipeline. Bolts safeguard the halves snugly. No special devices are required. Upkeep is reduced. HDPE doesn’t require painting. It cleans easily. The plastic is safe. It does not hurt aquatic life.

These drifts handle harsh seas. They stand up to impacts from debris. Temperature level adjustments don’t affect them much. Cold or hot water is great. The product remains flexible. It doesn’t end up being fragile. Buoyancy remains constant over time.

Making use of these HDPE drifts saves money. Their lengthy life lowers replacement expenses. Downtime for maintenance is less. The light-weight design makes handling simpler. Transport and deployment are easier. They are a reliable choice for dredging jobs.

(Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater)

Applications of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

Marine dredging operations need reliable pipe support. Our HDPE plastic pipe floaters deliver exactly that. These buoys keep dredge pipelines stable and afloat on water. They are built using tough high-density polyethylene plastic. This material withstands harsh marine conditions very well.

Saltwater causes serious problems for metal equipment. Rust and corrosion damage metal floaters fast. HDPE plastic won’t rust. It resists corrosion completely. This means much longer service life. You avoid constant replacements. Operations run smoother with less downtime.

Sunlight and UV rays degrade many materials over time. Our HDPE floaters resist UV damage effectively. They stay strong season after season. They handle impact well too. Bumps against boats or debris cause minimal harm. This durability saves significant money.

Installation is straightforward. The floaters clamp securely onto the pipeline. Workers can attach them quickly. Adjusting buoyancy is simple. You add or remove water inside the chambers. This ensures the pipeline sits at the perfect level. Stability is crucial for efficient sand and slurry transport.

Maintenance needs are minimal. HDPE plastic doesn’t require painting or special coatings. Just rinse them off occasionally. This cuts down on labor costs. It also reduces environmental concerns. No toxic paints wash into the water.

These floaters are lighter than traditional metal buoys. Handling them is easier. Transporting them costs less. Their modular design offers flexibility. You connect multiple units easily for longer pipeline sections. Adding or removing buoys takes little effort.

Using HDPE plastic floaters is a smart investment. They outlast metal alternatives significantly. Lower maintenance means lower operating expenses. Dredging projects stay on schedule. Your pipeline stays reliably afloat.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

Here are common questions about Marine HDPE Plastic Dredging Pipe Floats:

What are these floats made from? They use high density polyethylene plastic. This material is very tough. It handles harsh ocean conditions well. Salt water doesn’t damage it. Sunlight doesn’t break it down quickly. Rocks and debris cause little harm. This plastic lasts a long time.

How much buoyancy do they provide? Each float lifts a specific weight. The buoyancy depends on the float’s size and design. Common sizes support several hundred kilograms per meter of pipe. They keep the dredge pipeline high in the water. This prevents the pipe from sinking. Sand and slurry flow easily inside.

Are they easy to install? Yes, installation is straightforward. They snap together around the pipe. No special tools are usually needed. Workers connect them directly on the dredging line. This saves significant time during setup. Operations start faster.

Do they need maintenance? Almost none. The plastic resists fouling. Marine growth like barnacles doesn’t stick well. Cleaning is rarely necessary. They don’t rust or corrode ever. There are no moving parts to break. Just check them for major physical damage occasionally.

Why choose plastic floats over metal? Plastic floats are much lighter. Handling them is easier and safer. They cost less upfront. Their lifespan is longer. Metal corrodes in seawater. Plastic withstands impacts better. Replacement costs drop over time. Total ownership cost is lower.

(Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater)

REQUEST A QUOTE

RELATED PRODUCTS

HDPE Flexible Construction Plastic Tubes High Pressure Underground Water Supply Industrial Pressure System Drainage Tubing 6mm

High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

Wholesale Corrosion Resistant Industrial HDPE Pipe

High Density Polyethylene HDPE P6006 Extrusion Pipe Grade Virgin HDPE PE100 Black Color Pe100 Virgin Hdpe Granules for Pipes

High-Density PE Polyethylene Pipe Large Diameter 110mm-800mm Polyethylene Bellows Drainage

Hdpe Pipe s Hdpe Pipe Sdr11 Sdr17 Sdr 21 High Density Polyethylene Hdpe Pipe s

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677