LUOYANG DATANG ENERGY TECH CO.,LTD

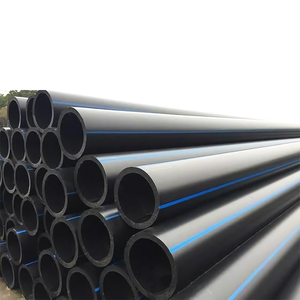

High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply

PRODUCT PARAMETERS

Description

Introduction of High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply)

Specifications of High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply

HDPE steel wire pipelines provide water dependably. They’re constructed difficult for water supply networks. This pipeline incorporates plastic stamina with steel reinforcement. Think plastic inside, steel cable reinforcement center, plastic outside. This split layout develops a very strong pipe. It takes care of high stress and withstands damages well.

The core product is High-Density Polyethylene. HDPE is smooth inside. This level of smoothness maintains water moving freely. It minimizes friction loss. Less rubbing indicates much better pressure over range. HDPE additionally stands up to chemicals and rust flawlessly. It won’t rust or break down like steel pipes. The steel cord layer adds incredible strength. This cord is wound securely around the internal plastic core. It offers the pipe high ring stiffness. The pipeline won’t quickly crush or deform under soil lots. An outer HDPE layer covers the steel wire. This outer layer safeguards the steel from dampness and scratches.

These pipes deal with high stress. Typical pressure scores are PN10, PN16, PN20, PN25. PN25 suggests it holds up against 25 bar stress. They come in lots of sizes. Diameters vary from small 63mm up to big 800mm. This suits numerous project demands. The pipe material functions well in chilly and moderate heat. Its operating temperature level array is typically -20 ° C to 50 ° C. It manages freezing ground problems penalty. Hot climates are fine also.

Versatility is an essential benefit. The pipeline can bend slightly throughout installation. This makes fitting it around obstacles easier. It minimizes the demand for additional joints. Less joints imply fewer potential leakage factors. The product is really light contrasted to conventional pipes like concrete or ductile iron. Lightweight pipelines are much easier to deliver and manage on website. This quickens installment. It reduces labor expenses. The jointing method usually entails warm combination. Combination creates a smooth, leak-proof connection. It’s as strong as the pipe itself.

HDPE steel cable pipe supplies long service life. Its resistance to deterioration and chemicals makes sure sturdiness. It withstands harsh dirt problems. It needs marginal upkeep over decades. This pipeline is a cost-efficient option for contemporary water supply.

(High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply)

Applications of High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply

HDPE steel cable pipe offers exceptional services for water tasks. Its toughness and versatility make it a leading option. The steel wire support inside the HDPE gives the pipe high pressure resistance. This suggests it takes care of the demands of large water pipe and transmission lines conveniently. It additionally withstands splitting under pressure surges usual in water supply.

These pipes endure harsh settings well. They do not rust like metal pipes. Chemicals in dirt or water will not harm them. This corrosion resistance guarantees clean water distribution over years. The pipeline product remains smooth inside. This smoothness minimizes friction loss. Water flows efficiently, saving pumping power over the pipeline’s long life.

Installation advantages are considerable. HDPE steel cord pipe is relatively light-weight. This makes transport and taking care of easier on website. Its versatility enables it to bend around challenges. This prevents numerous joints compared to rigid pipes. Less joints indicate fewer potential leak factors. Specialists can use trenchless approaches like straight directional boring. This minimizes surface disturbance in sensitive areas like cities or farmland.

The pipeline is tough versus ground movement. It can absorb stress and anxiety from quakes or shifting soil. This toughness protects against breaks and leaks. It functions dependably for river crossings or locations with unstable ground. The pipe material is risk-free for potable water. It fulfills rigorous health and wellness requirements. Water stays tidy and tastes great throughout the system.

HDPE steel cable pipeline provides trustworthy water circulation over long distances. Its durability makes sure reduced upkeep prices. Operators depend on it for vital water facilities projects. The mix of stamina, flexibility, and rust resistance makes it suitable.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply

Here are 5 common questions about HDPE Steel Wire Composite Pipes for water supply:

What makes HDPE Steel Wire Composite Pipe different?

This pipe combines layers. The core is strong HDPE plastic. Steel wires reinforce it. This design gives high strength. It also keeps flexibility. Plastic pipes alone can’t match this strength. Metal pipes alone lack this flexibility.

Why is this pipe so durable?

The materials are tough. HDPE plastic handles chemicals well. It resists corrosion. The steel wires add great strength. Together they resist cracks. They handle high pressure. They survive impacts. Ground movement like digs settle won’t break them easily. They last decades underground.

Is installation easier with this pipe?

Yes, installation is simpler. The pipe is lighter than metal pipes. Workers move it easily. It comes in long coils. This means fewer joints needed underground. Fewer joints mean fewer leak points. Workers connect sections fast using heat fusion. This makes a solid, leak-proof seal. No complex welding is required.

Is the water safe inside this pipe?

Yes, the water stays safe. HDPE plastic is very smooth inside. Scale and bacteria struggle to stick. The material won’t rust. It doesn’t corrode. It won’t add metals or bad tastes to the water. The pipe material meets strict drinking water standards.

Does this pipe save money over time?

Using this pipe often saves money long-term. Installation is faster and cheaper. Fewer joints cut labor costs. The pipe rarely leaks. It needs almost no maintenance. It doesn’t corrode or need replacement like metal pipes. Leaks waste water and money. Preventing leaks saves significant costs. The long lifespan spreads the initial cost over many years.

(High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply)

REQUEST A QUOTE

RELATED PRODUCTS

Pn6~16 High Density Polyethylene HDPE Pipe for Water Supply/Gas/Mining/Agriculture Irrigation/Drainage

High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic And Durable

High Density Polyethylene Sdr9 Sdr11 Sdr 13.6 Sdr17 Sdr21Hdpe Pipe Water Supply

HDPE Flexible Construction Plastic Tubes High Pressure Underground Water Supply Industrial Pressure System Drainage Tubing 6mm

High Density Polyethylene Sdr9 Sdr11 Sdr 13.6 Sdr17 Sdr21Hdpe Pipe Water Supply

PN8~16 High Density Polyethylene HDPE Pipe Dn20mm Dn315mm`dn1000mm HDPE PIPE For Water Supply

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677