LUOYANG DATANG ENERGY TECH CO.,LTD

PVC Water Hose Pipe Making Machine

PRODUCT PARAMETERS

Description

Introduction of PVC Water Hose Pipe Making Machine

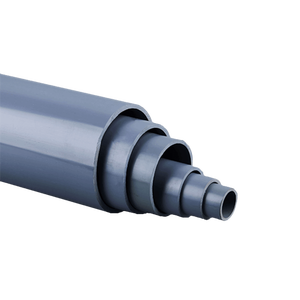

Polyvinylchloride (PVC) Pipe is a durable, lightweight, and cost-effective piping solution widely used in industrial, agricultural, construction, and plumbing applications. Made from high-quality polyvinyl chloride material, PVC pipes offer excellent corrosion resistance, smooth inner walls for efficient fluid flow, and long-term reliability in various environments.

Key Features of PVC Water Hose Pipe Making Machine

Corrosion & Chemical Resistance

Resistant to rust, chemicals, and acidic/alkaline substances, making them ideal for industrial and wastewater applications.

Lightweight & Easy Installation

Lightweight design reduces transportation and labor costs, while simple joining methods (e.g., solvent welding, threading) ensure quick installation.

Smooth Interior Surface

Minimizes friction loss, improving flow efficiency and reducing energy consumption in fluid transport systems.

High Strength & Durability

Withstands high pressure and impact, suitable for underground and above-ground installations.

Long Service Life

UV-resistant (if formulated) and unaffected by moisture, ensuring decades of low-maintenance operation.

Cost-Effective

Lower material and installation costs compared to metal pipes, providing an economical alternative.

Non-Toxic & Safe

Certified for potable water supply (lead-free formulations available) and compliant with international standards (e.g., NSF, ASTM).

Versatile Applications

Used in water supply, drainage, irrigation, electrical conduits, and industrial processing systems.

(PVC Water Hose Pipe Making Machine)

Specifications of PVC Water Hose Pipe Making Machine

Here’s the product content about PVC Water Hose Pipe Making Machine specifications. It uses simple language, basic transitions, and clear connections. The conclusion part is omitted.

This machine makes PVC water hose pipes. It produces different sizes. Common sizes are 1/2 inch, 3/4 inch, and 1 inch. The machine handles various PVC materials. You can use flexible PVC compounds. The machine needs raw PVC granules. These granules feed into the extruder. The extruder heats the PVC. It melts the PVC material. The melted PVC gets pushed through a die. The die shapes the melted PVC into a tube. This tube is the basic hose form. The machine has a cooling system. The hot hose tube moves into cooling tanks. These tanks hold water. The water cools the hose quickly. Cooling sets the hose shape. The machine pulls the cooled hose. A haul-off unit does this pulling. The haul-off speed controls the hose length. You set the haul-off speed. The machine cuts the hose. A cutter chops the hose to set lengths. You choose the cutting length. Common lengths are 50 meters or 100 meters per roll. The machine winds the finished hose. A winder collects the hose onto reels. Production speed is important. This machine makes about 15 to 25 meters per minute. The machine uses electricity. It needs three-phase power supply. Voltage is usually 380V or 415V. Power consumption is around 25 kW. The machine frame is strong steel. Key parts use stainless steel. This prevents rust. The machine has a control panel. Operators use the panel to run the machine. They adjust settings here. Settings include temperature, speed, and cutting length. The machine needs space. The total length is often 15 to 20 meters. Width is about 2 meters. Height is around 1.5 meters. The machine is heavy. Weight might be 2000 to 3000 kilograms. Installation needs a solid floor. Maintenance is necessary. Regular checks keep it running well. Operators need training. Training covers safe operation and basic troubleshooting. The machine makes reliable water hoses. These hoses are for gardens, farms, and industry.

(PVC Water Hose Pipe Making Machine)

Applications of PVC Water Hose Pipe Making Machine

PVC water hose pipe making machines build flexible pipes for water. These pipes serve many important purposes. Farmers rely on them heavily. They use the pipes for crop irrigation across large fields. The pipes carry water efficiently from sources to plants. Gardeners also need these hoses. They connect them to taps for watering lawns, flowers, and vegetable patches. Homeowners use them for washing cars and general outdoor cleaning tasks.

Industry depends on these PVC pipes too. Factories use them to move water and other safe liquids between machines or storage areas. Construction sites need large amounts of water. Workers use these hoses for mixing concrete, controlling dust, and general site cleaning. Firefighters require robust hoses. These machines make hoses suitable for firefighting equipment and emergency water supply lines.

Mines and quarries operate in tough conditions. They use durable PVC hoses for dewatering pits, washing minerals, and supplying water to remote locations. Municipalities install these pipes for temporary water lines during repairs or events. They also connect them to water trucks for distribution. Landscapers install sprinkler systems using pipe from these machines. The pipe withstands sun exposure and ground pressure.

Campgrounds and parks provide water access points using this hose. Factories need water for cooling processes. They install these pipes for reliable coolant transfer. The machines produce pipe in various diameters and pressure ratings. This flexibility meets diverse application needs. Businesses choose these machines for consistent, reliable hose production. The output pipes offer good value and long service life.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of PVC Water Hose Pipe Making Machine

What production capacity can this machine handle?

Our machine makes small to medium PVC water hoses. It handles diameters from 1/4 inch to 2 inches. Daily output reaches 200kg. Actual capacity depends on hose size and wall thickness. Thicker walls take more time. Operators adjust settings for different outputs.

What affects production speed?

Several things matter. Material quality is key. Good PVC compound flows smoothly. Machine temperature settings are crucial. Correct heating ensures proper melting. Cooling speed also impacts the line speed. Operator skill makes a difference. Experienced workers keep things running fast.

What raw materials does it use?

The machine uses PVC resin powder. Additives are necessary too. Plasticizers make the hose flexible. Stabilizers prevent heat damage. Colorants give the hose its color. The powder mix must be dry. Moisture causes problems during extrusion.

Can it make different hose types?

Yes. The machine is versatile. Change the extrusion die and screw design. This adjusts the hose diameter and wall. Adjust the plasticizer amount. This controls flexibility. Different colorants create various hose colors. Settings are modified for each product type.

What maintenance does the machine need?

Regular upkeep is essential. Clean the extruder screw and barrel daily. Lubricate moving parts weekly. Check heater bands and thermocouples often. Replace worn gears or belts promptly. Keep cooling systems clear. Good maintenance prevents breakdowns and keeps quality consistent.

(PVC Water Hose Pipe Making Machine)

REQUEST A QUOTE

RELATED PRODUCTS

Compression And Corrosion Resistance Plastic All Size Available Pipe And Fittings

Quality Customizable PVC Water Irrigation Pipe Various Specifications High Pressure

Whole High Pressure PVC Pipes Round Pipe PVC Plastic

ing Transparent PVC Hard Pipe Factory Multiple Size Pipes

Pipe Rigid Schedule 40 UPVC Water Supply Drainage

PVC Pipes Swimming Pool Plumbing Flexible Water Line

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677