LUOYANG DATANG ENERGY TECH CO.,LTD

High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating

PRODUCT PARAMETERS

Description

Introduction of High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating

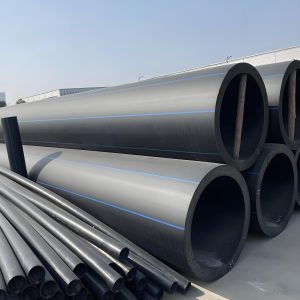

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating)

Specifications of High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating

These pipelines provide hot water for district furnace. They keep warmth inside successfully. The core is a strong steel pipeline. This steel pipe lugs the hot water under pressure. It is made from durable carbon steel. The steel pipeline is coated for extra rust security.

A thick layer surrounds the steel pipe. This layer is polyurethane foam insulation. Polyurethane foam is superb at quiting warmth loss. Heat doesn’t run away easily with this foam. The foam bonds securely to the steel pipeline. This bond protects against air spaces. Air spaces would let warmth retreat. The foam additionally adds architectural stamina.

A difficult external covering shields whatever. This covering is high-density polyethylene (HDPE). HDPE is extremely strong and flexible. It stands up to damages from weather condition, chemicals, and dirt stress and anxieties. The HDPE housing is totally water resistant. It maintains groundwater out of the insulation. Wet insulation loses its heat-trapping capability. The casing likewise safeguards versus physical effects throughout handling and interment.

The entire assembly is constructed for long life underground. The HDPE casing stops rust of the steel pipe. The polyurethane foam maintains heat inside the system. This lowers energy waste considerably. Less gas is needed to maintain water hot. The pre-insulated style streamlines setup. Employees lay one total pipeline section. They avoid mounting different insulation on website. This conserves significant time and labor prices.

The pipes take care of heats and stress common in district home heating networks. They stand up to ground motion well. The smooth HDPE surface area permits simple pulling through underground air ducts. Leak discovery cables are commonly incorporated during manufacturing. These cables aid find any kind of troubles rapidly. The system guarantees trusted, reliable warm distribution over years.

(High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating)

Applications of High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating

High thickness polyethylene pre-insulated pipes are essential for modern-day district heating unit. These pipes deliver warm water successfully from the main plant to buildings. The core framework features a steel service pipe carrying the warm water. This steel pipe is surrounded by rigid polyurethane foam insulation. This foam lessens heat loss throughout transportation. A hard outer housing of high thickness polyethylene protects everything. This casing guards the insulation and pipe from ground moisture and physical damage.

These pipelines deal with heats and pressures typical in district home heating networks. The HDPE case is highly immune to corrosion and chemicals discovered underground. This resistance indicates the pipelines last a long time with little maintenance. The polyurethane foam insulation carries out remarkably well. It keeps warmth inside the pipe efficiently. Less warmth loss equates straight to lower energy prices for the entire system. Operators conserve money and decrease lost power.

Installment is straightforward and fast. The pipes get here pre-insulated and ready to hide. Workers don’t need to protect them onsite. This saves substantial labor time and cost. The pre-insulated design makes sure constant, top quality insulation along the whole pipeline size. Leakages are less likely contrasted to older installation techniques. The joints in between pipeline areas are specially created. Employees bonded the steel internal pipes firmly. They after that secure the HDPE case and foam insulation around the joint. This produces a continuous, watertight, and thermally efficient system underground.

These pipelines supply a trustworthy service for increasing or upgrading home heating networks. Their resilience and low thermal conductivity make them ideal for long-lasting infrastructure projects. Cities and utilities rely upon them for effective warmth circulation. The robust construction takes care of requiring below ground conditions every year.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating

What are HDPE pre-insulated pipes for district heating?

These pipes carry hot water or steam for heating buildings across a town or city. They have a steel core pipe for strength. A layer of polyurethane foam surrounds the steel pipe. This foam provides excellent thermal insulation. A tough outer casing made of High-Density Polyethylene (HDPE) protects everything. The entire assembly is made in the factory.

Why use pre-insulated pipes for district heating?

Pre-insulated pipes minimize heat loss during transport. This saves energy and reduces operating costs. The HDPE casing shields the insulation and steel pipe from ground moisture and soil chemicals. This prevents corrosion. The factory-made design ensures consistent quality insulation. Leaks are less likely at the joints.

How hot can the water inside these pipes get?

The steel core pipe handles high temperatures. Systems typically operate with water up to 120-140°C (248-284°F). The polyurethane foam insulation keeps this heat inside the pipe. The outer HDPE casing withstands these temperatures reliably. Specific limits depend on the pipe design and material grades.

What makes installation easier with these pipes?

The pipes arrive at the site fully insulated and protected. Workers handle one complete unit. They connect sections using specialized fittings. This saves significant time compared to insulating pipes onsite. Leak detection wires are often built into the insulation. These help quickly find problems later.

How long do these pipes last underground?

The HDPE outer casing offers strong resistance to corrosion and chemicals. The steel core is protected from the soil environment. The polyurethane foam maintains its insulating properties for decades. Properly installed systems regularly last 30 years or more. Minimal maintenance is needed.

(High Density Polyethylene Pre-insulated Pipe Polyurethane Thermal Insulation Steel Pipe for District Heating)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality High Density Polyethylene HDPE Pipe Factory Whole High Pressure Water Supply for Irrigation Water Supply

High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

High-Temperature Resistant HDPE Gas Pipe

Professional UPVC Water Pipe Polyvinyl Chloride Drainage Head Water Irrigation Pipes

PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

PE Tube High Density Polyethylene Hdpe Pipe 110mm Hdpe Siphon Co-Layered Drainage Pipes

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677