LUOYANG DATANG ENERGY TECH CO.,LTD

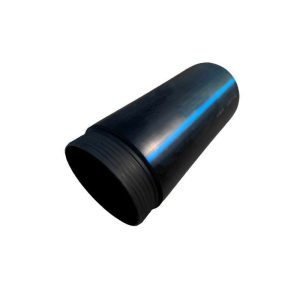

Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

PRODUCT PARAMETERS

Description

Introduction of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater)

Specifications of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

These aquatic dredging pipeline floaters keep sand discharge pipelines functioning successfully on water. They are constructed making use of high thickness polyethylene plastic. HDPE plastic is solid. It stands up to damage from salt water, sunlight, and chemicals usually discovered in digging up sites. This product does not rust like steel. It lasts a lot longer in challenging marine conditions.

Each drifter supplies reliable buoyancy. It lifts the dredging pipeline off all-time low. The pipeline stays near the water surface. This prevents dragging and lowers rubbing. Digging up procedures run smoother. Less power is required to pump the sand and water blend. The drifters can be found in various sizes. They match common dredging pipeline diameters. Typical dimensions support pipelines from 6 inches up to 24 inches or even more. You pick the ideal dimension for your pipe.

The style is simple and reliable. A main network holds the pipe firmly. Straps or clamps secure the pipe in position. This quits the pipeline from eloping. The body is solid HDPE. It is built as one item. There are no weak joints. The smooth form assists water flow past. It minimizes drag in currents. The advances are difficult. They take care of bumps and scrapes without breaking. They work in fresh water and seawater.

These HDPE advances are much lighter than old steel buoys. This makes them less complicated to take care of. Workers can move and install them swiftly. Less tools is required. Move prices are lower. Upkeep is very little. HDPE doesn’t need paint. It does not rot. Just wipe marine growth occasionally. The plastic is stable. It will not soak up water. The buoyancy remains consistent gradually. They are a functional choice for demanding dredging jobs. They maintain pipelines drifting correctly.

(Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater)

Applications of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

Marine HDPE plastic dredging pipeline drifters maintain dredging pipes working right. They provide buoyancy. This buoyancy quits the pipeline from sinking. It maintains the pipeline drifting at the right degree in the water. This is crucial for moving sand, silt, or debris successfully. Digging up staffs use these advances frequently.

Their major job is supporting digging up pipes. These pipes carry material from dredgers to the disposal area. Without correct drifters, the pipeline drags out the bottom. It causes rubbing. It wears out quick. It can even damage. Drifters avoid these problems. They make certain smooth product circulation.

These advances are vital for lots of water jobs. Digging up harbors and channels requires them. Maintaining port access calls for continuous sediment elimination. Coastal defense tasks use them. Beach nourishment depends on relocating big sand volumes. Land improvement projects rely on them. Offshore digging up procedures require robust pipeline assistance.

HDPE plastic is the very best material for these drifters. It takes care of severe seawater completely. Metal rusts in seawater. HDPE plastic does not corrosion or corrode. It lasts much longer. It stands up to effects from particles or ice. Sunshine (UV rays) doesn’t damage it severely. The product is extremely difficult.

HDPE advances are lighter than old-style steel drums. This makes them less complicated to deal with. Setup is quicker. Retrieval is easier. They need little upkeep. You just clean them often. They don’t require paint or special finishes. This saves cash gradually.

The challenging HDPE plastic holds up against harsh conditions. Waves and currents continuously struck the drifters. They stay solid. They keep the pipe stable. This security is essential for effective dredging. Downtime expenses cash. Trustworthy advances minimize downtime.

These advances connect firmly to the pipeline. Various dimensions fit different pipeline sizes. They provide constant buoyancy along the entire pipeline length. This maintains the dredge pump functioning efficiently. It relocates material without clogs.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

What is this floater made of?

It uses tough HDPE plastic. HDPE stands for High-Density Polyethylene. This material handles harsh ocean conditions well. Saltwater doesn’t rust it. Sunlight doesn’t break it down fast. Chemicals in the water won’t harm it much. It lasts a long time.

How much weight does one floater support?

Each floater holds up a specific pipe section filled with water and sand. Buoyancy depends on pipe size and water depth. Common sizes support several hundred kilograms. Bigger pipes need stronger floaters. Check the product specs for exact numbers matching your pipe.

How do you attach it to the dredge pipe?

The design is simple. The floater clamps around the pipe. You tighten strong straps or bolts. This keeps it secure. No welding is needed. Installation is quick. Workers can do it on the barge or dock. It fits standard pipe diameters.

Why choose plastic over steel floaters?

Plastic offers big advantages. Steel rusts in seawater. Plastic doesn’t. Steel needs painting. Plastic doesn’t. Plastic is lighter. This makes handling easier. Plastic costs less over time. It needs almost no upkeep. Plastic survives bumps better. It doesn’t dent.

What maintenance does it need?

Very little. Rinse it with fresh water sometimes. This removes salt and sand. Check the straps or bolts yearly. Make sure they are tight. Look for big scrapes or cracks. Fix minor damage with marine epoxy. Replace the floater only if badly broken. It saves time and money.

(Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater)

REQUEST A QUOTE

RELATED PRODUCTS

Durable HDPE Corrugated Flexible Irrigation & Drainage Pipe High-Density Polyethylene Underground Cable Protection Plastic Tubes

HDPE Plastic Tubes PE Water Supply Pipe Drainage Irrigation Pipe

Wholesale HDPE Plumbing Pipes With ISO Certification

High Density Black Polyethylene Gas Pipe

HDPE High-Density Polyethylene Corrugated Perforated Grooved Drainage Plastic Pipe New Type Lightweight Durable Material

High Density Polyethylene (HDPE) Pipe for Industrial Fire Fighting Water Systems 6mm Flexible High Pressure Socket Butt Fusion

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677