LUOYANG DATANG ENERGY TECH CO.,LTD

Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

PRODUCT PARAMETERS

Description

Introduction of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

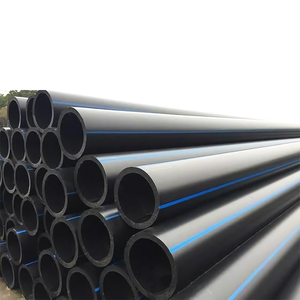

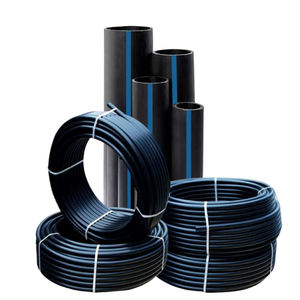

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials)

Specifications of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT is a leading quality virgin plastic basic material. It’s made particularly for premium pipeline production. This material gives pipelines exceptional strength and long life. The granules are developed for smooth extrusion molding procedures.

Key specs specify this HDPE quality. Its thickness is generally around 0.952 g/cm SIX. This thickness provides good rigidity and stress resistance. The Melt Flow Index (MFI) has to do with 0.25 g/10 minutes (190 ° C/5 kg). This reduced MFI is essential. It ensures the thawed plastic flows continuously during pipe extrusion. Constant flow avoids issues like irregular wall surface density.

Tensile toughness at yield is high, roughly 26 MPa. This means pipelines made from TR480AT can manage substantial interior pressure. They stand up to fracturing or bursting well. The product additionally uses excellent environmental tension split resistance (ESCR). Pipes last much longer underground or in challenging problems.

Influence strength is an additional strong point. TR480AT HDPE takes in shocks successfully. Pipes won’t smash quickly if struck. This is crucial for hidden pipeline applications. Thermal security is dependable. The product processes well within common HDPE extrusion temperature levels.

Chemical resistance is exceptional. HHM TR480AT withstands lots of acids, alkalis, and solvents. This protects pipes from rust. It’s suitable for water supply, water drainage, and commercial fluid transportation. The material fulfills common pipe criteria. It supplies consistent top quality set after set. Makers trust it for requiring pipe tasks. Its residential properties ensure sturdy, trusted pipeline performance over years.

(Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials)

Applications of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

TR480AT HDPE granules use a leading choice for pipe makers. This high-density polyethylene material is pipeline quality. It originates from virgin plastic resources. The granules are especially made for extrusion molding. This procedure shapes thawed plastic right into continuous accounts. Pipelines are the major item. Home builders and designers count on this HDPE for requiring pipe systems.

Its stamina is a significant advantage. TR480AT creates pipes that take care of high pressure well. These pipes stand up to cracking under tension. They last for years without breaking down. Water pipes are a common usage. Gas circulation systems likewise count on this product. Industrial liquid transport benefits as well.

Sturdiness issues greatly. HDPE like TR480AT fights chemicals efficiently. Acids, alkalis, and salts don’t harm it easily. This makes it risk-free for different liquids. The product additionally stands up to severe weather. Sunlight, rain, and temperature adjustments cause very little damage. Below ground pipes stay solid versus soil pressure and moisture.

Installation is easier. HDPE pipelines are lighter than metal or concrete choices. Employees move and attach them quicker. The material allows flexible pipeline designs. This flexibility aids in limited spaces or irregular ground. Leaks take place much less commonly at joints as a result of excellent combination welding.

The smooth inner surface area is essential. It minimizes rubbing inside the pipe. Water or other liquids move more successfully. Much less energy pumps liquids with the system. Blockages from buildup are less likely. This keeps upkeep expenses lower in time.

TR480AT provides consistent quality. Virgin product makes sure trustworthy properties batch after batch. Cpus locate it foreseeable during extrusion. This dependability suggests less production troubles. Producers obtain steady pipe efficiency. Building jobs depend on this consistency. Water energies and gas firms demand it. Plant need it for smooth operations.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

What is HHM TR480AT HDPE Granules? HHM TR480AT is a pipe grade high density polyethylene. This material is virgin HDPE. It comes as granules. These granules are for extrusion molding. They make strong plastic pipes.

What are the main uses of this material? It is for water pipes. It is for gas pipes. It is for sewage systems. It is for industrial pipes. The material handles pressure well. It works in tough conditions.

What makes HHM TR480AT special? It has high density. It has good stiffness. It resists impacts. It handles chemicals. It has strong tensile strength. It lasts long. These traits suit pipe needs.

How do you process HHM TR480AT? Use extrusion machines. Melt the granules. Shape the melted material. Cool it into pipes. The granules flow smoothly. They are easy to process. This saves time and energy.

Why pick virgin HDPE for pipes? Virgin material is pure. It has no recycled content. This gives consistent quality. It avoids weak spots. It meets high standards. It prevents pipe failures. It ensures safety.

(Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials)

REQUEST A QUOTE

RELATED PRODUCTS

Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage

HDPE Flexible Construction Plastic Tubes High Pressure Underground Water Supply Industrial Pressure System Drainage Tubing 6mm

3LPE Anti-Corrosion Spiral Pipe 3PE Urban Water Supply Pipeline With ASTM SABS Certificates For Drill Pipe And Structure Use

Professional HDPE LDPE PP ABS Pehd Pipe Machine

PE100 High Density Polyethylene Water Pipe SDR26 SDR21 SDR17 SDR13.6 SDR11 Water Supply and Drainage HDPE Pipe

Pn8~16 High Density Polyethylene Hdpe Pipe Dn20mm Dn315mm`dn1000mm Hdpe Pipe for Water Supply

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677