LUOYANG DATANG ENERGY TECH CO.,LTD

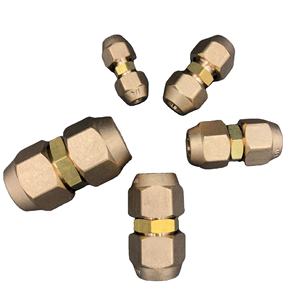

High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining

PRODUCT PARAMETERS

Description

Overview of High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining

High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining provides reliable, long-lasting connections for all your plumbing and HVAC system needs. Manufactured from lead-free, dezincification-resistant brass alloy, these fittings meet strict industry standards for performance and safety. Perfect for both residential and commercial applications, our brass fittings create secure, leak-proof joints in water supply lines, gas systems, and compressed air installations.

Key Features of High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining

Premium Material – Lead-free, DZR brass for corrosion resistance

Secure Connections – Precision threads for leak-proof seals

Temperature Resistant – Suitable for hot & cold water systems

Versatile Applications – Works with copper, PEX, and PVC pipes

Certified Quality – NSF/ANSI 61 & 372 certified for potable water

Multiple Configurations – Elbows, tees, couplings, adapters available

(High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining)

Specifications of High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining

These parts are high precision brass elements made by CNC turning and milling. Devices reduced them to specific sizes. We make use of brass and copper. These metals function well for machining. They resist corrosion. They last long in difficult problems.

Our CNC turrets make these parts. The machines spin the material quickly. Reducing tools shape it precisely. Every component matches the style completely. Tolerances are limited. We determine parts meticulously. This guarantees they fit ideal every single time.

We likewise do milling procedures. Milling makers reduced ports, holes, and intricate forms. This occurs after turning or individually. CNC control means consistent results. Set after set stays the very same. Quality is dependable.

Brass is the main product. It’s solid. It machines conveniently. It deals with water and chemicals well. Copper alloys are made use of also. They use great electric conductivity. We choose the best metal for the task.

These elements go into many sectors. Pipes installations require leak-proof links. Electrical adapters require exact get in touch with points. Automotive components should withstand vibration and heat. Industrial shutoffs manage flow accurately. Medical gadgets need sterile, dependable components. Our components satisfy these demands.

Accuracy is key. Parts should fit together completely. They must function efficiently. Even small errors cause troubles. Our machining prevents those errors. We focus on accuracy. This makes assemblies work better. It decreases wear and tear. Performance boosts in general.

Consumers get customized parts or basic ones. We follow their drawings exactly. Tiny runs or huge volumes are possible. Quick manufacturing keeps jobs relocating. Reliable delivery matters. Good parts keep makers running.

(High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining)

Applications of High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining

High precision brass CNC transforming makes important parts for lots of industries. These parts must be extremely exact. They fit perfectly inside devices and systems. You discover them in autos, aircrafts, medical tools, and electronics. They manage liquids and gases. They attach various items securely.

These elements are turned on CNC turrets. The turret rotates the brass extremely quickly. A sharp cutting tool shapes it precisely. This technique makes round parts like adapters, valves, installations, and sleeves. It obtains the dimension specifically right. The surface remains smooth. This smoothness aids seals function better. Leakages are less likely.

Milling makers likewise service these brass pieces. Milling cuts shapes that aren’t round. It makes ports, holes, apartments, and complex accounts. Milling includes details the lathe can refrain alone. Transforming and milling with each other make total, complex components. Brass and copper are outstanding materials. They stand up to corrosion well. They deal with warmth and pressure. They conduct electrical power efficiently. They are also simple to equipment. This keeps production expenses down.

The CNC devices follow computer system directions flawlessly. This means every component is virtually the same. Consistency is essential for makers to work right. Quality assurance checks every measurement. Components need to meet stringent criteria. Trustworthy performance depends upon this precision. These parts keep makers running smoothly. They stop failings. They are necessary for contemporary innovation. Suppliers trust these high accuracy brass elements. They require parts they can trust. Our machining delivers that reliability. We make certain each item satisfies the precise spec.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining

Here are common questions about our high-precision brass CNC turning parts:

What materials do you typically use?

We mainly machine brass and copper alloys. These materials offer excellent machinability and corrosion resistance. They are ideal for demanding fluid and gas systems. We select specific alloys based on your project’s strength and environmental needs.

How precise can you machine these components?

Our CNC lathes and milling machines achieve very tight tolerances. We routinely hold dimensions within +/- 0.005 inches or tighter. Complex geometries are handled accurately. This precision ensures parts fit perfectly in assemblies every time.

What industries use these precision brass parts?

Many industries rely on these components. Hydraulic systems, pneumatic controls, medical devices, and instrumentation use them heavily. Plumbing fittings, automotive fuel systems, and electrical connectors also depend on their precision and reliability.

Can you handle custom designs?

Yes, custom designs are our specialty. Provide your drawings or specifications. We use advanced CAD/CAM software. We program our CNC machines to produce parts exactly to your requirements. Prototyping and large production runs are both possible.

How do you ensure quality?

Quality control is critical throughout our process. We perform in-process checks during machining. Final inspection uses calibrated tools like micrometers and CMMs. We verify dimensions, surface finish, and thread accuracy. This guarantees every part meets your standards before shipment.

(High Precision Brass CNC Turning Fitting Machinery Components High Precision Lathe Turned Brass Copper Parts Milling Machining)

REQUEST A QUOTE

RELATED PRODUCTS

Whole Popular Brass Ball Valves Practical Hot Brass Ball Valves With Bsp/Npt

Factory Whole Low Support Customizable Specifications Earth Rod Accessories Brass Coupling

Refrigeration Brass Flare Nut 1/4 3/8 1/2 in SAE Brass Pipe Fittings

Hot ing 90 Degree Stainless Steel Quick Fitting Outer Wire Elbow with Brass Head Pipe Fittings-90 Carbon Steel Degree Elbow

Brass Fittings Factory 1/2”-2” Hardware BSP Male Female Threaded Brass Pipe Fittings

PEIFENG Lead-Free Fitting F1807 PEX Brass Straight Quick Connector Plumbing Connectors Fitting

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677