LUOYANG DATANG ENERGY TECH CO.,LTD

The Ultimate Guide to Underground Piping: Types, Uses & Best Materials PVC, HDPE & PEX

Choosing the right underground piping is critical for durability and efficiency. This guide explains the importance of selecting corrosion-resistant, weatherproof materials like PVC, HDPE, and PEX pipes for water supply and drainage systems. Learn how soil conditions, local climate, and installation methods influence your choice, and explore common applications beyond residential use. Ensure long-term performance and avoid costly repairs with expert advice tailored to modern underground piping needs.

Subheading 1: What is Underground Piping?

Imagine the veins that carry life-sustaining resources throughout your body. Underground piping serves a similar purpose for your home or city—it’s a hidden network of pipes installed beneath the surface, transporting clean water to your taps and efficiently removing wastewater. Think of it as an essential, out-of-sight highway system for water.

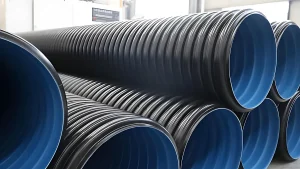

Due to exposure to water pressure, varying soil conditions, and extreme temperatures, selecting the right pipe material is crucial. Common options include PVC pipes, copper, HDPE pipes, and PEX pipes. Each offers distinct advantages tailored to this demanding, concealed application.

Subheading 2: The Importance of Selecting the Right Underground Piping

Choosing the wrong type of underground piping can lead to significant issues down the line. Leaks are a primary concern—they often go undetected for extended periods, wasting water, destabilizing soil, and even damaging foundations. Repairing buried pipes is not only costly but also highly disruptive. Additionally, corrosion from soil composition or water quality can degrade certain materials over time, while freezing conditions may cause less durable pipes to crack.

Investing in the appropriate underground piping material helps prevent these problems, ensures long-term performance, and protects both your property and resources.

Subheading 3: How to Choose the Best Underground Piping

Selecting the ideal underground water pipe involves evaluating several factors:

1. Local Building Codes: Always adhere to regulations that specify approved materials.

2. Soil Conditions: Corrosive or rocky soils may require robust, non-reactive materials like HDPE or PVC pipes.

3. Water Properties: Treated municipal water and well water have different chemical characteristics that affect pipe longevity.

4. Climate: Ensure pipes are buried below the frost line to avoid freezing.

5. Installation Method: Trenchless installations benefit from flexible options like HDPE pipes, while traditional trenching accommodates more rigid materials.

6. Cost vs. Lifespan: Durable solutions may have higher upfront costs but offer better long-term value.

Consulting with a professional plumber familiar with local conditions can help you make an informed decision.

Subheading 4: Applications of Underground Piping Beyond Residential Use

Underground piping systems support more than just household water supply. Municipalities rely on extensive networks of buried mains to distribute water from treatment plants and connect fire hydrants. Agriculture depends on underground piping for efficient irrigation, while industrial sites use heavy-duty pipes for process water and waste management.

In new construction developments, installing reliable underground water systems is a critical first step. Choosing durable, corrosion-resistant materials like PVC, HDPE, and PEX pipes reduces maintenance costs and enhances system longevity across all these applications.

Subheading 5: Frequently Asked Questions About Underground Piping

1. Is PVC pipe good for underground water lines?

Yes, PVC pipe is a popular choice due to its corrosion resistance, affordability, and ease of installation. Schedule 40 PVC is commonly used for buried water lines, though it should be installed below the frost line to prevent brittleness in cold climates.

2. How deep should underground pipes be buried?

Depth depends on the local frost line—typically between 12 to 36 inches. Always consult local building codes to ensure correct installation depth.

3. Can PEX pipe be used underground?

PEX pipe can be used underground, preferably inside a protective conduit or sleeve for added defense against soil pressure and pests. Direct burial is possible with specific outdoor-rated PEX variants.

4. Which lasts longer underground: copper or plastic?

Plastic pipes such as HDPE and PVC generally outperform copper underground due to superior corrosion resistance and flexibility. Copper is prone to degradation in acidic or saline soils.

5. Are galvanized steel pipes suitable for underground use?

No. Galvanized steel is susceptible to internal corrosion, reduced water flow, and eventual leakage. Modern alternatives like HDPE, PEX, and PVC pipes are recommended for new installations.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PPR pipes,Brass Valves and brass fittings, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net