LUOYANG DATANG ENERGY TECH CO.,LTD

Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes

PRODUCT PARAMETERS

Description

Overview of Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes

Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes)

Specifications of Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes

These API 5L X52 seamless steel pipes are built tough for demanding oil and gas pipeline systems. They meet the strict API 5L specification for line pipe. The X52 grade means the steel has a minimum yield strength of 52,000 psi. This high strength is vital for handling the pressures found in petroleum transport.

The pipes are seamless (SMLS). They are formed without welding a seam along their length. This seamless construction makes them inherently stronger. They are more reliable under high pressure. They resist leaks better than welded pipes. This is especially important for critical pipeline sections.

Available in common sizes DN150 (6 inches) and DN200 (8 inches). Both sizes come in Schedule 40 (Sch 40) wall thickness. This schedule provides a good balance. It offers strong pressure containment. It keeps the pipe weight manageable for installation. Sch 40 is a standard thickness widely used in mid-pressure oil and gas applications.

Carbon steel (CS) is the base material. This steel offers good strength and durability. It performs well in typical pipeline environments. Proper coatings and cathodic protection are still needed for long-term corrosion resistance underground or underwater.

Manufacturing involves piercing solid steel billets. The steel is heated and shaped into a hollow tube. This process ensures a uniform structure throughout the pipe wall. The pipes undergo rigorous testing. This includes hydrostatic testing to check for leaks under high water pressure. Non-destructive testing (NDT) methods like ultrasonic or radiographic inspection scan for hidden flaws. These tests guarantee the pipes are sound and safe for operation. API 5L certification confirms the pipes meet all required chemical and mechanical properties.

(Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes)

Applications of Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes

API 5L X52 SMLS thick DN150 DN200 Sch 40 CS seamless steel pipes are built tough. They handle demanding oil and gas jobs. The steel grade is X52. This means high strength. The pipes are seamless (SMLS). This construction avoids weld seams. Weak spots are eliminated. Pipe walls are thicker (Sch 40). This adds strength. These pipes manage high pressure well. They resist bursting. Leaks are less likely.

DN150 and DN200 sizes are common. They fit many pipeline systems. Carbon steel (CS) is the base material. It offers good performance. It handles crude oil and natural gas effectively. Corrosion resistance is suitable for many conditions. Extra protection might be needed sometimes.

These pipes are vital upstream. They move oil and gas from wells. Gathering lines use them. Production lines use them. They also work downstream. Refineries employ them. Petrochemical plants use them. They connect equipment safely. High pressure is common here. Seamless construction is key. It ensures reliability.

Pipeline transport relies on these pipes. They form long-distance networks. Strength and leak resistance are critical. Safety depends on it. Environmental protection depends on it. Their dimensional accuracy helps. Installation is smoother. Connections are more secure.

Offshore platforms need robust piping. Harsh sea conditions demand it. These X52 seamless pipes deliver. They withstand saltwater exposure. They handle platform vibrations. Onshore facilities use them too. Pump stations need them. Compressor stations need them. Processing units need them.

Maintenance is important. Regular checks are essential. Proper installation matters. These pipes offer long service life. They are a dependable choice. They meet API 5L standards. Quality is assured. Performance is proven in the field.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes

What is API 5L X52?

API 5L X52 is a steel grade standard. This standard is set by the American Petroleum Institute. X52 means the pipe has a minimum yield strength of 52,000 psi. This strength is important. It helps the pipe handle high pressure safely. The pipe is made for transporting oil and gas.

What sizes do these pipes come in?

These pipes are available in DN150 and DN200 sizes. DN stands for Diameter Nominal. DN150 is about 6 inches in outside diameter. DN200 is about 8 inches in outside diameter. Schedule 40 tells you the wall thickness. Schedule 40 is a common thickness for standard pressure piping.

What does Schedule 40 mean?

Schedule 40 refers to the wall thickness of the pipe. It is a standard classification. For DN150 pipe, Schedule 40 wall thickness is about 7.1 mm. For DN200 pipe, Schedule 40 wall thickness is about 7.9 mm. This thickness provides good strength. It balances pressure handling and material use.

Why use seamless (SMLS) pipe?

Seamless pipe means the pipe has no welded seam. It is formed from a solid steel billet. This process makes the pipe very strong. It has uniform strength all around. Seamless pipe is better for high pressure. It is better for critical applications like oil and gas lines. Welded pipe has a seam that could be a weak point.

Where are these pipes mainly used?

These pipes are designed for the petroleum industry. They transport crude oil. They transport natural gas. They transport refined petroleum products. They are used in gathering lines. They are used in transmission pipelines. They are used in distribution networks. The API 5L standard ensures they are safe and reliable for these uses.

(Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes)

REQUEST A QUOTE

RELATED PRODUCTS

Astm API 5l Gr B A134 A106 A53 SCH 40 Black MS Iron Pipe Hot Rolled Seamless And Welded Carbon Steel Tube

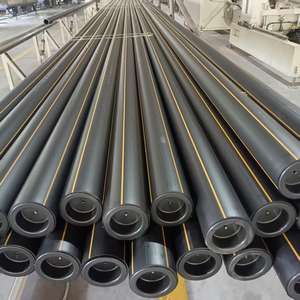

Factory Direct PE Plastic Gas Pipe

Gas PE Pipe s HDPE Yellow Gas Pipe Dn20mm to 630mm

Promotion Hot Rolled Carbon Ms Mild Ssaw Round Black Di 300mm Thick 4mm 2500mm Diameter Welded Spiral Steel Pipe/tube

Galvanized Steel Pipe/hose/tube For Water Gas Galvanized Steel Tube 45 X 45 X 2mm 4m Long

Hot Astm Seamless Carbon Steel Pipe/seamless Pipe Manufacture/smls Pipe

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677