LUOYANG DATANG ENERGY TECH CO.,LTD

Professional Guide for the Use of PPR Pipes in Commercial and Public Buildings

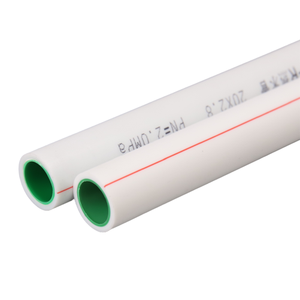

As the complexity of building functions increases, commercial and public buildings have higher requirements for the reliability, hygiene and operating costs of water supply and drainage systems. PPR pipes stand out in cold and hot water distribution and domestic hot water systems due to their excellent physicochemical properties: the material is inert, does not rust, has a smooth inner wall, reduces scaling and bacterial adhesion, and significantly reduces maintenance frequency and operational risks.

Design points: Differentiate system parameters by application

In large buildings, domestic hot water, cold and hot water supply, and circulation circuits should be designed separately. When choosing PPR pipes, determine the PN value and wall thickness of the pipes based on the maximum operating temperature of the system, design pressure and circulation frequency (for example, short-term high-temperature tolerance should be considered for hot water circulation). Also reserve thermal expansion and contraction displacements and reasonable support and hanger spacing to avoid stress concentration caused by temperature deformation.

Construction and connection: The hot melt process ensures sealing

The hot-melt and socket connection process of PPR is its construction advantage: uniform joints, low leakage rate. The contractor is required to strictly adhere to the hot melt temperature, heating time and cooling process, and keep records of the pressure holding test. The construction site should be protected from strong light and chemical splashes. The cut end face should be kept flat and deburred before welding to ensure fluid and water quality safety.

Certification and Acceptance: Compliance is the pass to the project

Engineering procurement should give priority to products that have passed industry certifications such as ISO 15874 / GB/T/DIN and provide factory test reports. During the acceptance stage, batch traceability, physical property test curves and drinking water contact certification should be verified to ensure that the project passes regulatory and property acceptance and reduces the risk of claims later.

Operation and maintenance as well as energy-saving value

The low thermal conductivity of PPR reduces heat loss and saves energy for both hot water systems and underfloor heating circuits; Smooth inner walls reduce adhesion, improve heat exchange efficiency and extend system life. The operator should establish a network file, conduct regular pressure and temperature inspections, and adopt intelligent control for hot water circulation to reduce energy consumption.

Implementation Recommendations (for engineering and procurement parties)

Identify the system zoning and maximum operating conditions, and select PPR pipes that match the PN/SDR grade.

Ask the supplier to provide complete certification and batch test reports.

The contractor must be trained in the hot melt process and keep the pressure holding test sheet.

Design reserved maintenance access ports and hydraulic balance measures to facilitate later operation and maintenance.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PPR pipes,Brass Valves and brass fittings, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net