LUOYANG DATANG ENERGY TECH CO.,LTD

Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes

PRODUCT PARAMETERS

Description

Overview of Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes

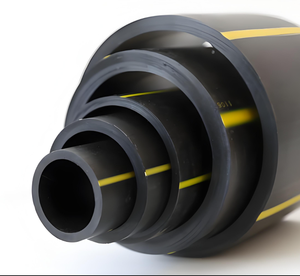

Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes)

Specifications of Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes

These pipes move fluids like oil, gas, or water over long distances. They are carbon steel pipes. They are strong and durable. They meet the API 5L standard. This standard is important for pipeline safety and performance.

Common grades are API 5L Gr B, X52, and X60. Grade B is a good standard strength pipe. X52 pipes are stronger than Grade B. X60 pipes are even stronger. Higher grades handle more pressure. Higher grades are good for tougher jobs.

These pipes are seamless. This means no welded seam along their length. Seamless pipes are made from solid steel billets. The billets are heated and pierced. Then they are stretched over a mandrel. This creates a hollow tube. Seamless construction is key. It gives uniform strength all around the pipe. It avoids weak spots. It handles high pressure very well. It resists leaks better.

These pipes come in specific sizes. Wall thickness is called schedule. Common schedules are SCH 40, SCH 80, SCH 160. Thicker walls handle higher pressure. Outer diameters range from small to very large. Lengths are usually random or fixed. Exact sizes depend on the project needs.

They undergo strict testing. Hydrostatic testing checks for leaks under high water pressure. Non-destructive testing (NDT) looks for hidden flaws. Common NDT methods are ultrasonic or radiography. Chemical analysis confirms the steel mix. Mechanical tests check tensile strength and yield strength. Hardness might also be tested. This ensures the pipes are reliable.

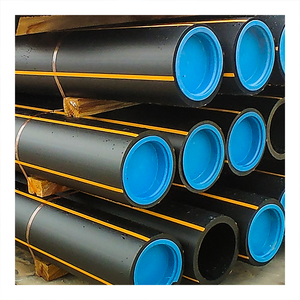

Surface finish is often plain or coated. Black paint or varnish prevents rust during storage and transport. Sometimes a light anti-corrosion oil is used. End protection is important. Plastic caps stop damage to the pipe ends. They keep dirt out.

You need pipes that last. You need pipes that work under pressure. These API 5L seamless pipes deliver. They are made for demanding fluid transport systems. They keep things flowing safely.

(Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes)

Applications of Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes

Fluid pipeline carbon steel pipes meet the API 5L standard. Grades like GrB, X52, and X60 are common. Seamless tubes are a key type. These pipes move fluids under pressure. Their strength and reliability are vital.

The oil and gas industry uses these pipes heavily. They form the backbone of gathering lines. They work in transmission pipelines moving crude oil. They move natural gas over long distances. They are essential for refined products pipelines. Offshore platforms depend on them. They handle the harsh subsea environment well.

Water infrastructure needs these pipes too. Large water mains carry drinking water. They transport wastewater for treatment. Irrigation systems use them for moving water efficiently. They handle the constant pressure reliably.

Industrial plants rely on these seamless tubes. They connect process equipment. They move steam for power generation. They carry chemicals safely within facilities. Their seamless construction prevents leaks. This is critical for safety.

Construction projects use these pipes. They form piles for strong foundations. They act as casing for concrete structures. They provide structural support in buildings. Their durability is important here.

These pipes are chosen for high-pressure jobs. They resist corrosion effectively. They handle temperature changes well. Seamless manufacturing means no welded seams. This makes them stronger. Leaks are less likely. They last a long time with proper care.

Energy companies install them for power plants. Mining operations use them for slurry transport. Municipalities choose them for water systems. Factories install them for process lines. They serve reliably in many demanding situations.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes

What exactly are these fluid pipeline pipes?

These are seamless steel tubes. They transport liquids or gases. They are made from carbon steel. They meet strict API 5L standards. Grades include Gr B, X52, and X60. Seamless means no welded seams. This makes them strong and reliable.

Why choose carbon steel for pipelines?

Carbon steel is very tough. It handles high pressure well. It’s also cost-effective. This material works for many demanding jobs. It resists wear and tear effectively. It’s a proven choice for long pipelines.

What do API 5L Gr B, X52, X60 mean?

These are steel strength grades. API 5L is the standard. Gr B is a common grade. It offers good basic strength. X52 is stronger than Gr B. X60 is stronger still. Higher numbers mean stronger pipes. The grade needed depends on the project pressure.

What sizes do these seamless pipes come in?

They come in many sizes. Outer diameters vary widely. Wall thicknesses also vary. Common sizes are readily available. Special sizes can often be ordered. Check supplier specifications for exact options.

Do these pipes resist rust well?

Carbon steel can rust. Protection is important. These pipes often get coatings. Common coatings are epoxy or paint. They can also be galvanized. The environment decides the best protection method. Proper coating greatly extends pipe life.

(Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe

Pressure-Rated HDPE Gas Pipe PE100, EN 1555 Certified**

Hot ASTM A106 API 5L X42 X52 X62 X65 Gr.b S355j2 20MnV6 Seamless/Welded Pipe PSL1/PSL2 Oil And Gas Pipeline

ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe

API5CT J55 Material Casing Pipe Heat Resistant Carbon Steel Tube For Oil & Gas And Water EN & ASTM Standard Welding Service

HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677