LUOYANG DATANG ENERGY TECH CO.,LTD

API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline

PRODUCT PARAMETERS

Description

Overview of API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline

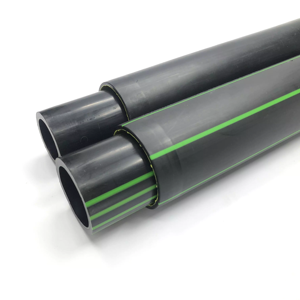

API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline)

Specifications of API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline

These pipes carry oil and gas long distances. They are built tough. The pipes follow API 5L standards. Common grades are X42 and X50. These grades mean high strength. The steel handles high pressure safely. Pipes also meet A53 and A106 Gr.B specs. These are common standards too. The material is carbon steel. This steel is reliable for pipelines.

Pipe sizes vary a lot. Diameters range from small to large. Wall thickness options exist. Thicker walls handle more pressure. You get the size needed for your project. Lengths are usually long. This helps reduce field welds.

A key feature is the coating. Pipes get a 3-layer polyethylene (3LPE) coating. This coating protects the outside. It stops rust and corrosion. The coating is very durable. It handles rough soil and weather. The coating sticks well to the steel. This stops water getting underneath. Three layers work together. First, epoxy bonds to the pipe. Next, adhesive sticks to the epoxy. Finally, tough polyethylene covers everything. This system lasts decades underground.

Manufacturing is strict. Pipes are tested carefully. They check chemical makeup. They test mechanical strength. Hydrostatic tests prove pressure rating. Inspectors check dimensions. They look for defects. Coating thickness and adhesion are verified. Quality control is constant. This ensures pipes perform safely. These pipes are a proven solution for transmission lines. They offer strength, protection, and long life.

(API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline)

Applications of API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline

These pipes transport oil and gas over long distances. They are built tough. The API 5L X42 and X50 grades are common choices. These grades handle high pressure well. They are reliable for demanding pipeline projects. Steel pipes like A53 and A106 Gr.B are also used. They serve similar purposes in other systems.

Protection is crucial underground or underwater. These pipes feature a special 3-layer polyethylene coating. This coating shields the steel pipe. It stops rust and corrosion effectively. The coating has three distinct layers. First, an epoxy layer bonds tightly to the steel. Second, a middle layer sticks to the epoxy and the top layer. Third, a thick polyethylene layer forms the tough outer shell. This system creates an excellent barrier.

The coating prevents pipeline damage. It stops soil chemicals and moisture from attacking the steel. This protection extends the pipeline’s life. It reduces maintenance costs significantly. Pipeline operators need this durability. It ensures safe, continuous operation for decades.

These pipes connect sections of the transmission line. They are welded together securely. The pipes carry the product under pressure. The X42 and X50 grades offer specific strength levels. Engineers select the right grade for the project pressure. The coating is applied at specialized plants. Quality control is strict throughout. Pipes must meet API standards exactly. This guarantees performance and safety.

The coated pipes are ready for installation. They are shipped to the construction site. Crews lay them along the planned route. The robust coating resists handling damage. It also withstands harsh soil conditions. This keeps the pipeline secure. It prevents leaks and environmental harm. Using these pipes is a smart investment. It protects the pipeline asset effectively.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline

What exactly are these pipes used for?

These steel pipes move oil and gas long distances underground or underwater. They form the main arteries of transmission pipeline systems. The pipe carries the product safely from production fields to refineries or storage facilities. It handles high pressure and tough conditions.

What kind of steel makes these pipes?

The pipes use strong carbon steel. API 5L pipes meet grades like X42 or X50. These grades mean the steel has specific minimum strength levels. A53 and A106 Gr.B pipes also use carbon steel. All types are made for demanding service.

What sizes are available?

Manufacturers offer many sizes. Common outside diameters range from 2 inches up to 48 inches or more. Wall thickness varies significantly too. The right size depends on the pipeline’s required flow rate and pressure. Suppliers list standard sizes, custom sizes are possible.

Why use the 3-layer polyethylene coating?

This coating is crucial protection. It stops the steel pipe from corroding underground. The coating shields the pipe from soil chemicals and moisture. It greatly extends the pipeline’s working life. The coating is tough and resists damage during handling and burial.

What’s the difference between API 5L and A53/A106 pipes?

API 5L pipes are specifically designed for long-distance oil and gas transmission lines. They follow strict requirements for toughness and welding. A53 pipes are often used for lower pressure utility lines. A106 Gr.B pipes are common in refinery process piping and high-temperature service. Each standard suits different applications.

(API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline)

REQUEST A QUOTE

RELATED PRODUCTS

China Large Diameter Full Range Of Material Customization API 5L X60 X65 X70 Welded Carbon Steel Pipe/Tube For Building Material

ERW Steel Welded 1mm Round Hollow Pipe 2 Inch Galvanized Pipe Steel Tube Hot Dipped Galvanized Gi Pipe For Greenhouse

Q195 Q215 Q345 Q275 Carbon Steel Round Square Tube Pipe ASTM GB JIS DIN BS Carbon Steel Pipes

ASTM A53 Gr. B ERW Carbon Steel Pipe Welded Round Pipe for Petroleum and Natural Gas Pipelines and Buildings

Low ASTM Hot Rolled Carbon Seamless Steel Pipe 20# 45# Seamless Steel Tube

6mm-20mm Thick Steel Tube SSaw 609 MM Carbon Steel Pipe Section Helical Seam Spiral Welded JIS API Certified For Oil Gas 6m

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677