LUOYANG DATANG ENERGY TECH CO.,LTD

PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation

PRODUCT PARAMETERS

Description

Overview of PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation

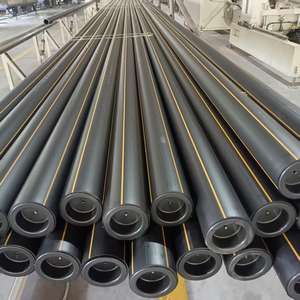

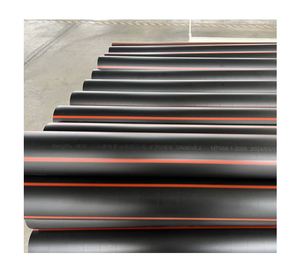

PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation)

Specifications of PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation

Below are the requirements for PSL1 X42/L290 and X52/L360 line pipes utilized in oil and gas transport. These pipelines dependably relocate oil and gas under pressure. They fulfill stringent international requirements.

The grades define the pipe’s strength. X42/L290 pipes use good strength. X52/L360 pipes are stronger. This toughness assists the pipes take care of high pressure inside. Both qualities come from the PSL1 category. PSL1 covers standard demands for line pipeline.

Dimension issues for these pipes. They are available in various sizes. Usual sizes vary from small to large. Wall surface density varies as well. Thicker walls handle greater pressure. The specific size needed relies on the project. Pipe size is usually long. This reduces area welding.

Production methods are very important. These pipes are seamless or welded. Seamless pipelines have no joint. Welded pipes have a longitudinal joint. Both kinds are solid and reputable. The production procedure makes certain top quality.

The pipelines are made from carbon steel. This steel has particular chemical elements. Carbon, manganese, silicon are crucial parts. The exact mix controls toughness and weldability. Appropriate chemistry makes welding easier. Great welds are critical for safety and security.

Testing validates the pipe high quality. Every pipe undertakes hydrostatic testing. This test loads the pipe with water under high pressure. It checks for leakages and strength. Other examinations examine product residential properties. Tensile tests procedure strength. Durability tests make sure the steel will not fracture conveniently.

Pipe ends are prepared for signing up with. Ends can be plain or beveled. Beveled ends await welding. Threaded ends are likewise feasible. Threads enable fast connections. Completion type relies on the setup approach.

Surface area defense is vital. Bare pipes obtain coverings. These finishings protect against rust. Common finishes include varnish or light oil. This defense functions during storage space and transport. Permanent deterioration layers are used later on, in the area.

These pipes are tough. They resist cracking. They perform well in different temperatures. They bend without damaging. This ductility is necessary during installment and use. Cautious manufacturing guarantees regular top quality.

(PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation)

Applications of PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation

PSL1 line pipelines in qualities like X42/L290, X46/L320, X52/L360 are crucial workhorses for moving oil and gas. They develop the foundation of countless transmission pipes worldwide. Operators pick these certain qualities due to the fact that they use a great mix of strength and expense. They offer sufficient pressure ability for lots of basic pipeline projects without the higher cost of top-tier grades.

These pipes lug crude oil, gas, and improved products like fuel cross countries. They link production areas to refineries, storage space terminals, and circulation centers. The pipelines safely consist of the pressurized materials over hundreds of miles. X42/L290 pipes are a typical beginning factor for reduced stress lines. X52/L360 pipelines take care of greater stress, making them suitable for several mainline applications.

The PSL1 specification means these pipes satisfy essential high quality and testing needs. They are trustworthy under typical operating problems. They are made from carbon steel. The steel supplies good weldability and strength for regular settings. Producers follow the API 5L requirement. This ensures consistent efficiency and dimensions.

You see these pipelines mounted underground, undersea, and over ground. They cross diverse surfaces like deserts, farmlands, and forests. Their stamina handles the interment lots and operating tensions. They develop the main arteries of the power network. Firms use them for new building and construction and also to replace older pipelines. Their balance of performance and value keeps them in high demand.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation

PSL1 X42/L290 and X52/L360 Line Pipe FAQs

What are PSL1 X42/L290 and X52/L360?

These are standard grades for steel pipe transporting oil and gas. PSL1 means basic quality requirements are met. X42 and X52 are older US designations. L290 and L360 are newer ISO designations. L290 equals X42 strength. L360 equals X52 strength. These pipes handle moderate pressure pipelines.

Where are these pipes typically used?

They are common choices for gathering lines and transmission lines. Gathering lines move oil or gas from wells to processing. Transmission lines carry it longer distances. They are suitable for many onshore applications. They also work for some offshore sections. The specific grade chosen depends on the operating pressure needed.

What testing is required for PSL1 pipe?

PSL1 pipe must pass certain checks. Every pipe undergoes hydrostatic testing. This test checks for leaks under high pressure. It also confirms the pipe won’t burst. Chemical analysis of the steel is done. This checks the material composition. Mechanical tests confirm strength and toughness. These tests happen on samples from each heat of steel.

How is corrosion protection handled?

External corrosion is a major concern. These pipes get coated externally. Common coatings include fusion-bonded epoxy (FBE). This creates a barrier against soil and moisture. Internal corrosion depends on the fluid. Sometimes internal coatings are applied. Cathodic protection is often used too. This adds an extra layer of defense underground.

What are the standard dimensions?

These pipes come in various sizes. Diameters range from small (e.g., 2 inches) to large (over 48 inches). Wall thickness varies significantly. Thicker walls handle higher pressures. Specific dimensions follow API 5L or ISO 3183 standards. The buyer specifies the exact diameter and wall thickness needed for their project.

(PSL1 X42/L290 X52/L360 Line Pipe for Oil / Gas Transportation)

REQUEST A QUOTE

RELATED PRODUCTS

Pvc lpg Gas Pipe

Sch40 Thick Wall Carbon Steel Seamless Pipes

Factory Direct PE Plastic Gas Pipe

Customized Welded Carbon Steel Pipe Bending Pipes Steel 90 Deg Elbow

2500mm 450mm Diameter 24 Inch Ssaw Carbon Spiral Welded Steel Pipe 1962a Sch 80 For Oil Gas Water

Astm A106b/a53 Gr. B Seamless Schedule 40 Carbon Steel Pipe Used For Oil And Gas Pipeline

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677