LUOYANG DATANG ENERGY TECH CO.,LTD

HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas

PRODUCT PARAMETERS

Description

Overview of HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas

HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas)

Specifications of HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas

These HDPE/MDPE 22.5-degree arm joint installations connect pipelines smoothly. They transform the direction of your gas pipeline carefully. The 22.5-degree angle gives a smaller turn than basic 45 or 90-degree joints. This is useful in tight spaces. It helps in reducing anxiety on the pipe system. It additionally assists keep great flow rates.

These installations are made from solid polyethylene plastic. HDPE (High-Density Polyethylene) and MDPE (Medium-Density Polyethylene) prevail options. Both products stand up to rust very well. They manage natural gas securely. These plastics are tough. They last a very long time underground.

Installment uses the butt fusion method. You heat up the pipeline end and the suitable end with special tools. You press the heated surface areas together. They thaw and fuse. This develops one solid, watertight joint. The joint is as solid as the pipeline itself. Proper blend is vital for safety. Always use experienced service technicians and certified devices.

These joints function especially for natural gas distribution systems. They fulfill rigorous sector criteria for gas pressure and worldly top quality. Try to find installations certified for gas usage. The smooth internal surface minimizes friction. Gas moves efficiently. The fused joint creates a long-term, trusted seal. This protects against leakages.

The main benefits are clear. These fittings offer a reputable, low-maintenance link. They withstand chemicals discovered in soil. They deal with the pressure demands of gas networks. The combination procedure develops sturdy joints. The 22.5-degree bend provides precise transmitting choices. This helps maximize pipeline layouts. It lowers the demand for doglegs.

(HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas)

Applications of HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas

This 22.5-degree HDPE or MDPE elbow pipe installation connects plastic pipelines bring natural gas underground. It alters the pipeline instructions a little. The angle is very important for navigating around challenges or adhering to land shapes smoothly. You join this suitable completely to pipelines utilizing butt blend.

Butt fusion home heating thaws completions of the pipeline and the suitable. You press the warm ends together. They cool and fuse into one solid piece. This creates a very solid joint. The joint is as solid as the pipe itself. It quits leakages entirely. Leakages are dangerous with gas.

HDPE and MDPE plastics resist rust well. They do not rust like steel. Chemicals in dirt don’t damage them. This makes the pipelines and fittings last a very long time underground. The smooth plastic inside also aids gas flow conveniently. This lowers stress loss.

These 22.5-degree elbows work well in gas distribution networks. They link pipes under roads and neighborhoods. They prevail in service lines running to homes and organizations. The combination joint stays sealed against gas under pressure. It deals with ground activity as well. The joint stays versatile.

Setup needs skilled crews and special combination machines. Correct blend is vital for safety and security. Workers comply with rigorous procedures. They cleanse the pipe finishes. They warm them to the ideal temperature. They fuse them correctly. This makes sure a best, permanent seal every single time. These fittings are a reliable choice for safe gas distribution.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas

What is a 22.5-degree HDPE/MDPE butt fusion elbow fitting?

This fitting connects HDPE or MDPE natural gas pipes. It changes the pipeline direction by 22.5 degrees. Butt fusion welding joins it permanently to the pipe ends. This creates a strong, leak-proof joint essential for gas systems.

Why use a 22.5-degree elbow instead of sharper bends?

A 22.5-degree bend is gentler. It reduces stress inside the pipe. Sharp bends create more resistance to gas flow. This gentler angle keeps pressure more stable. It also minimizes turbulence inside the line.

What pressure can this elbow fitting handle?

The pressure rating depends on the fitting’s size and material grade. Manufacturers clearly state the Pressure Rating Number (PN) for each fitting. You must select a fitting rated for your system’s maximum operating pressure. Never exceed the PN rating.

Can I use this elbow with any HDPE/MDPE pipe?

No. The pipe and fitting must be exactly the same material grade. They also need the same Outside Diameter (OD). Matching material ensures a proper, strong fusion weld. Using mismatched pipe or fittings risks joint failure.

Are these fittings certified for natural gas?

Yes, reputable fittings meet strict standards for gas use. Look for certifications like ISO 4437-2 or ASTM D2513. These confirm the fitting is safe and suitable for natural gas distribution. Always verify certification before purchase.

(HDPE/MDPE Butt Fusion 22.5 Degree Elbow Pipe Fitting For Natural Gas)

REQUEST A QUOTE

RELATED PRODUCTS

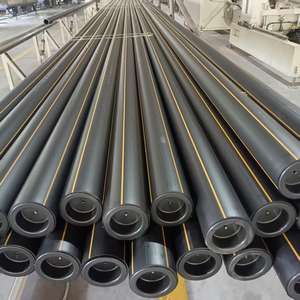

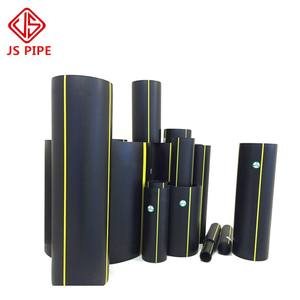

Gas PE Pipe s HDPE Yellow Gas Pipe DN20mm to 1600mm

Factory Direct PE Plastic Gas Pipe

Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe

Astm A36 St52 Q235 Q345 Q355 Q500 Hot Rolled Round Welded Seamless Carbon Steel Tube Pipe

ASTM A283 T91 P91 4130 42CrMo A106 A53 Grade B Mild Carbon Sch40 Seamless Steel Pipe

Gi Hollow Pipe 20mm 25mm 40mm 65mm 80mm 100mm 150mm For Gas

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677