LUOYANG DATANG ENERGY TECH CO.,LTD

PPR vs HDPE vs PVC:Industrial Water Supply Pipe Comparison

When planning an industrial water supply system, choosing the right piping material is one of the most critical decisions. The selection impacts not only the initial investment but also long-term operation, durability, and maintenance costs. This article compares PPR pipes and fittings, HDPE pipes, and PVC pipes in terms of performance, cost, and service life, helping project managers and procurement teams make an informed choice.

Why Pipe Material Matters in Industrial Water Supply

The pipe material defines the reliability and efficiency of an industrial water supply system. A well-chosen material ensures consistent water flow, minimizes leakage risks, and extends the lifecycle of the system. Industrial supply systems often operate under high pressure, varying temperatures, and sometimes exposure to aggressive chemicals—making proper material selection essential.

Cost Considerations: Initial vs Lifecycle

When comparing PPR pipes and fittings, HDPE pipes, and PVC pipes, procurement teams should evaluate both initial costs and lifecycle costs. Initial cost covers material purchase and installation, while lifecycle cost includes maintenance, energy efficiency, and replacement frequency. PPR pipes and fittings often have a slightly higher initial cost than PVC, but their extended lifespan and reduced maintenance can lower total ownership costs.

Performance Comparison: PPR vs HDPE vs PVC

Temperature and Pressure Resistance

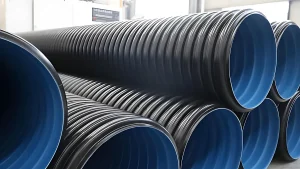

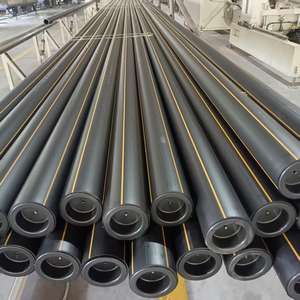

PPR pipes and fittings are well-suited for hot and cold water applications, offering high resistance to temperature variations. HDPE pipes perform excellently under high pressure and are resistant to cracking. PVC pipes, while cost-effective, are less suitable for high-temperature environments.

Durability and Chemical Resistance

Industrial systems often carry water containing minerals or chemicals. PPR pipes and fittings are highly resistant to scaling and corrosion. HDPE pipes provide superior resistance to chemical corrosion and are commonly used in aggressive fluid environments. PVC pipes resist many chemicals but are more brittle under stress.

Installation and Maintenance

PPR pipes and fittings are lightweight and easy to weld, ensuring leak-free joints. HDPE pipes require fusion welding, which offers strength but requires trained installers. PVC pipes are easy to cut and join, but joints may weaken over time under high load.

Case Example: Industrial Water Supply in a Manufacturing Plant

In a medium-sized manufacturing facility requiring stable hot and cold water supply, the engineering team evaluated PPR, HDPE, and PVC options. Despite a slightly higher upfront investment, PPR pipes and fittings were selected for their balance of cost-efficiency, long service life, and ease of installation. The system has operated for years with minimal maintenance costs, proving the value of lifecycle savings.

How to Choose the Right Pipe for Your Industrial Water Supply

When choosing between PPR pipes and fittings, HDPE, or PVC, consider:

– Water temperature and pressure conditions

– Expected chemical exposure

– Installation budget and timeline

– Maintenance capability and availability of skilled labor

By aligning pipe material with operational conditions, businesses can avoid costly downtime and ensure long-term efficiency in their industrial water supply systems.

Get Expert Advice on PPR Pipes and Fittings

If you are planning or upgrading an industrial water supply project, our team can provide tailored guidance on PPR pipes and fittings, HDPE pipes, and PVC pipes. Contact us today to receive detailed technical specifications and a customized quotation for your project needs.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PPR pipes,Brass Valves and brass fittings, please do not hesitate to contact us!