LUOYANG DATANG ENERGY TECH CO.,LTD

Water Supply Pipes Comparison Between PEX Pipes and PPR Pipes

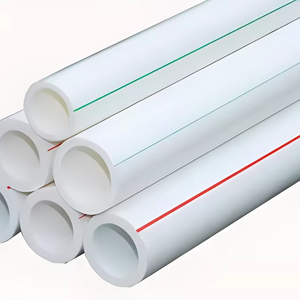

In modern buildings, the choice of water supply pipes is an important step. PEX (cross-linked polyethylene) Pipe and PPR (polypropylene) Pipe are two common materials for water supply pipes, each with its own unique advantages and disadvantages.

Material Properties are Important Considerations When Choosing Water Supply Pipes

PEX pipes are made of cross-linked polyethylene and have good flexibility and heat resistance. This makes PEX pipes easier to install, capable of bending without breaking, and suitable for complex piping layouts. PPR pipes, made of polypropylene, are more rigid and suitable for straight laying. They can withstand higher pressure, but in some cases, they are prone to cracking due to external forces.

Differences in Heat Resistance Between PEX Pipes and PPR Pipes

PEX pipes have a wider temperature range and can typically withstand temperatures between -40 ° C and 95 ° C, making them suitable for cold and hot water systems. PPR pipes, on the other hand, have a relatively narrow temperature range, typically between 0 ° C and 80 ° C. Although they perform well at normal temperatures, they may deform in high-temperature environments. In hot water supply scenarios, PEX pipes have more advantages.

Both PEX and PPR pipes perform well in terms of corrosion resistance. Both are not easily affected by water quality, do not rust or corrode, and are suitable for water supply systems of various water qualities. However, PEX pipes may be slightly less tolerant to certain chemicals, especially in environments with strong acids and strong alkalis, and special attention should be paid when using them.

Differences in installation PEX Pipes and PPR Pipes

The installation of PEX pipes typically uses hot-melt connections or special joints, which are relatively simple to operate and can be done without the need for a lot of tools. Its flexibility allows for a reduction in the use of joints during construction, thereby lowering the risk of leakage. The installation of PPR pipes, on the other hand, requires the use of hot-melt welding technology, which, although securely connected, demands specialized equipment and certain skills, thus taking a relatively long time during construction.

Both PEX and PPR pipes have a long service life. Generally speaking, PEX pipes can last for more than 50 years, while PPR pipes can last for more than 30 years. Although both are durable enough, in practical applications, PEX pipes perform more stably under extreme temperatures and pressures.

Comparison Between Production Cost:PEX VS PPR

Economy is also an important consideration when choosing pipes. The production cost of PEX pipes is relatively high, so they may seem more expensive in terms of initial investment. But it may be more cost-effective in the long run because of its longer service life and lower maintenance costs. By contrast, PPR pipes have a lower initial cost and are suitable for projects with limited budgets, but they may increase subsequent costs in terms of maintenance and replacement.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PPR pipes, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net