LUOYANG DATANG ENERGY TECH CO.,LTD

What are the differences between PE pipes and HDPE pipes?

The difference between HDPE pipes and PE pipes is a question that is often asked. It seems simple, but few people explain it clearly. Here we will systematically introduce it to you.

PE pipes are Polyethylene plastic pipes. As the most basic type of plastic, PE has excellent resistance to most household and industrial chemicals. Common plastic bags, cling film, etc. are all made of PE.

PE pipes as a whole can be classified into three types: low-density polyethylene pipes (LDPE pipes), medium-density polyethylene pipes (MDPE pipes), and high-density polyethylene pipes (HDPE pipes).

1. Low density polyethylene (abbreviated as LDPE)

Low-density polyethylene is generally produced by high-pressure polymerization with a density of 0.9910 -0.925g/cm ³. The molecular structure of low-density polyethylene is a linear macromolecule with many side chains. The side chains of different lengths on the main chain affect the regularity of the macromolecule arrangement, and the stacking is not tight, which hinders the crystallization of polyethylene. Therefore, the crystallinity is 55% -65%. Low-density polyethylene has a low melting point and a soft texture. The long side chains give it low viscosity at high shear rates during processing and high melt strength during stretching, making it very suitable for the blown film process and mainly used in the production of agricultural films, heavy packaging films, etc.

2. Medium-density polyethylene (MDPE for short)

Medium-density polyethylene (MDPE) is controlled in density by A-olefin copolymerization at medium and low pressures using an efficient catalyst

(0.926-0.940q/cm3), with a crystallinity of 70%-80%. Due to its numerous and long side chains, density and crystallinity decrease, medium-density polyethylene has better flexibility and low-temperature properties, and its tensile strength, hardness, thermal properties, etc. are inferior to those of high-density polyethylene. Due to the fact that copolyolefin can increase the intergranular linking chains of the crystal sheets of medium-density polyethylene, its resistance to slow cracking and long-term retention of mechanical strength are greatly improved compared to LDPE. Medium-density polyethylene can be used in the production of pressure pipes, delivery pipes, various containers and packaging films.

3. High-density Polyethylene (HDPE for short)

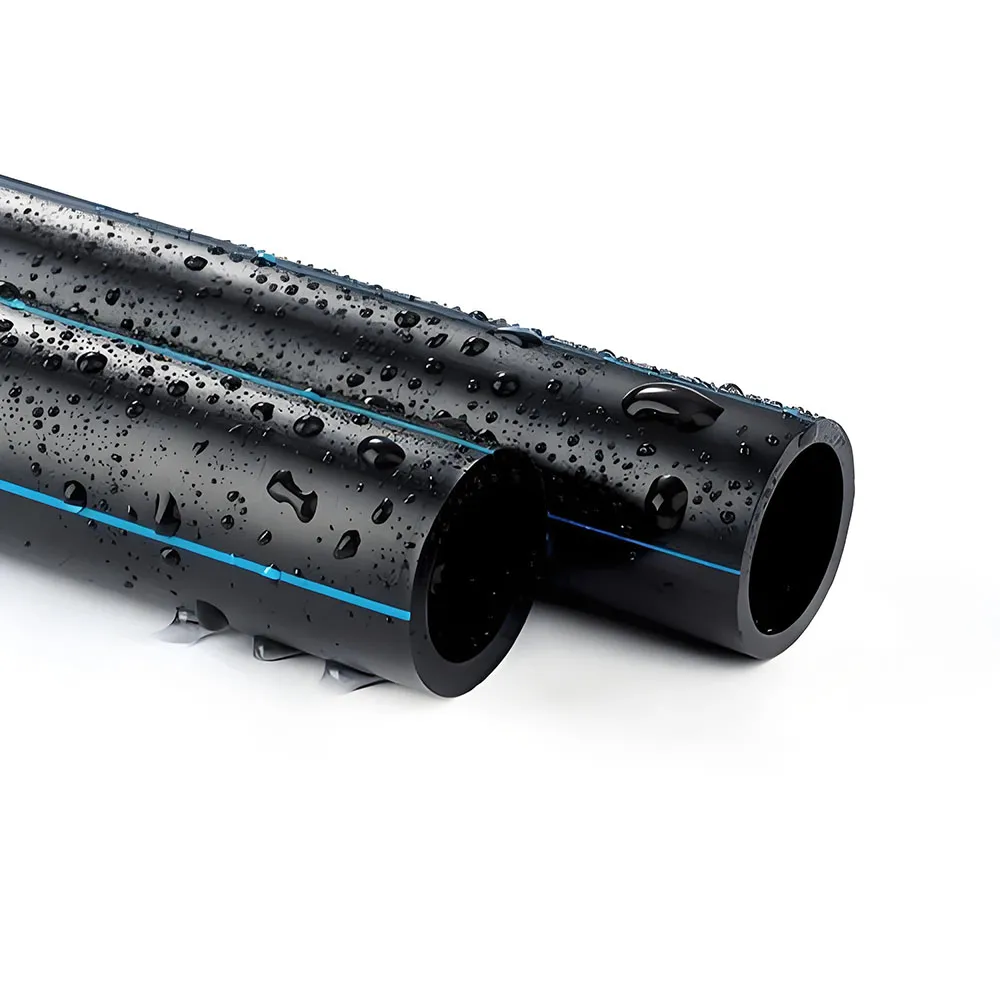

High-density polyethylene (HDPE) is produced by a low-pressure polymerization process, is linear, has a density of 0.94-0.965q/cm ³, has a crystallinity of 80%-95%, and is a white powder or granule. Compared with low-density polyethylene, it has fewer other sub-chains, a nearly linear structure, regular and close-packed molecules, and thus has high crystallinity, high density, relative molecular mass ranging from hundreds of thousands to hundreds of thousands, and a narrow range of melt flow rates. High density polyethylene has high rigidity and toughness, good mechanical strength and heat resistance, as well as good resistance to deep agents and steam penetration. High-density polyethylene has the lowest permeability among all types of polyethylene, the strongest corrosion resistance, and good rigidity, and is mainly used in the production of various pressure pipes, injection molded products, etc.

HDPE pipe is a type of PE pipe, but the performance of HDPE pipe is superior to that of ordinary PE pipe, which we can summarize as follows:

1, Different pressure resistance:

HDPE pipes must be able to withstand certain pressures, and usually a high molecular weight and good mechanical properties PE resin is chosen, such as HDPE resin, which is nine times stronger than ordinary polyethylene pipes (PE pipes);

2, the wear resistance is different

Among all engineering plastics, HDPE has the best abrasion resistance. The higher the molecular weight, the more wear-resistant the material is, even more than many metal materials (such as carbon steel, stainless steel, bronze, etc.) the abrasion resistance of common PE is only one-tenth of that of HDPE;

3, Different uses

General PE pipes (medium-density polyethylene pipes) are suitable for transporting gaseous artificial gas, natural gas, liquefied petroleum gas, while low-density polyethylene pipes are flexible tubes;

HDPE pipes (high-density polyethylene pipes) are mainly used for transporting natural gas, municipal engineering water supply systems, indoor water supply systems of buildings, outdoor buried water supply systems and buried water supply systems in residential areas and factories, old pipeline repair, water treatment engineering pipeline systems, and industrial water pipes in gardens, irrigation and other fields.

HDPE pipes can be used as a replacement for traditional steel pipes and polyvinyl chloride drinking water pipes, which ordinary PE pipes cannot.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PVC Pipe & PE Pipe in Agricultural Irrigation, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net