LUOYANG DATANG ENERGY TECH CO.,LTD

What Kind of Pipe For Underground Water Supply?

Choosing the right underground water pipe isn’t about finding the cheapest option today; it’s about safeguarding your water supply and infrastructure for decades. The inherent strength, leak-proof fused joints, and exceptional corrosion resistance of HDPE pipe make it the intelligent, long-term solution trusted by engineers and utility managers worldwide.

Why Underground Pipe Choice Matters Deeply

Durability Under Pressure Buried pipes endure constant soil pressure, potential ground movement (settling, freezingthawing), and heavy surface loads. Weak pipes crack or collapse.

Corrosion Resistance Soil chemicals, moisture, and stray electrical currents relentlessly attack metal pipes. Corrosion leads to leaks, reduced water flow (scale build-up), and water quality issues.

Leak-Free Joints Poorly joined pipes are the primary source of costly water loss and potential contamination ingress in underground systems.

Long Service Life Excavating and replacing failed pipes is incredibly disruptive and expensive. The right pipe lasts 50+ years.

Water Quality Protection The pipe material must not leach harmful substances (like lead or chemicals) into your drinking water.

Top Contenders for Underground Water Lines Pros & Cons

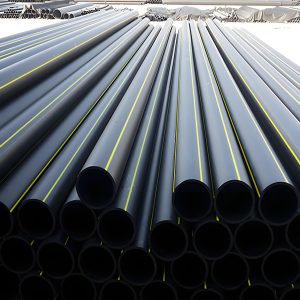

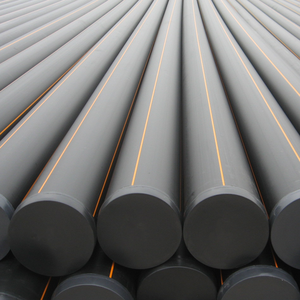

HDPE (High-Density Polyethylene) Pipe

- Unmatched Durability & Flexibility Withstands ground movement and freezing without cracking. Resists impact exceptionally well during installation and service.

- Superior Corrosion & Chemical Resistance Immune to rust, electrolysis, and most soil chemicals – ideal for harsh environments.

- Fused Joints = Zero Leaks Heat-fused joints create a seamless, monolithic system stronger than the pipe itself, eliminating the 1 failure point.

- Very Long Lifespan Consistently rated for 50-100+ years of service.

- Excellent Flow Characteristics Smooth interior surface minimizes friction loss, maintaining pressure and flow over long distances.

- Lightweight & Flexible Easier, faster installation with fewer fittings, reducing labor costs. Can be installed using trenchless methods (directional drilling) minimizing surface disruption.

- Resistance to Biological Growth Inhibits biofilm buildup inside the pipe.

- Considerations Requires specialized fusion equipment and trained crews for jointing. Needs proper anchoring at connections to rigid structures.

- UV protection needed if stored above ground long-term.

- Best For Municipal mains, industrial supply, agricultural irrigation, rugged terrain, areas with high corrosion potential or seismic activity. Our flagship product line focuses on premium HDPE solutions.

PVC (Polyvinyl Chloride) Pipe The Cost-Effective Standard

- Lower Initial Material Cost Generally less expensive than HDPE or metal pipes upfront.

- Corrosion & Chemical Resistance Excellent resistance to most soil conditions and water-borne chemicals. Won’t rust.

- Rigidity Holds shape well under soil pressure when properly bedded.

- Easy Solvent Cement Jointing Simple installation process widely understood by plumbers.

Considerations

- Brittleness Can crack under impact (especially in cold weather during handlinginstallation) or from sharp rocks in the bedding. Prone to failure under significant ground movement or freezing.

- Joint Reliability Solvent-cemented joints are strong but are the most common point of potential failure compared to HDPE fusion. Gasket-sealed joints also used.

- Temperature Limitations Can become brittle in extreme cold and softenweaken in very hot conditions.

- Environmental Concerns Production and disposal raise some environmental questions (though recycling exists).

- Best For Smaller diameter residential service lines, irrigation laterals, where initial cost is paramount and ground conditions are stable.

Beyond Material Critical Factors for Your Project

Pressure Rating Select pipe rated for the system’s maximum operating pressure (PSI) plus a safety factor. Consider surge pressures (water hammer).

Size (Diameter) Determined by required flow rate (GPM) and acceptable pressure drop over the distance. Undersized pipes cause low pressure; oversized pipes are unnecessarily costly.

Soil Conditions Highly corrosive soils Rocky bedding High water table These influence material choice and installation methods (e.g., sand bedding for PVC).

Local Codes & Regulations Always comply with municipal or regional building codes specifying approved materials, installation depths, and procedures.

Installation Quality This is paramount! Proper trenching, bedding, jointing, and backfilling according to manufacturer specs and industry standards (like ASTM) are essential for any pipe’s long-term performance. Poor installation can ruin the best pipe.

Certifications Ensure pipes carry relevant certifications for potable water (e.g., NSFANSI 61, WRAS, KIWA). All our HDPE and PVC pipes meet or exceed stringent global potable water standards.

The Clear Winner for Modern Underground Water Supply HDPE

While PVC has its place for smaller, cost-sensitive applications, and copper persists in limited roles, HDPE pipe consistently emerges as the superior choice for demanding, long-lasting, and leak-free underground water supply systems. Its unparalleled combination of flexibility, corrosion resistance, fused joint integrity, durability, and long lifespan offers the lowest lifetime cost and highest reliability for most municipal, commercial, industrial, and larger residential projects.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PPR pipes,Brass Valves and brass fittings, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net