LUOYANG DATANG ENERGY TECH CO.,LTD

ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines

PRODUCT PARAMETERS

Description

Overview of ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines

ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines)

Specifications of ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines

ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipeline Fittings attach pipelines. These tees are important parts in oil and gas systems. They sign up with 3 pipelines of the exact same dimension. The equivalent design suggests all 3 openings match. This guarantees constant circulation at the branch point.

These installations purely comply with the ANSI B16.9 standard. This requirement specifies dimensions, tolerances, and ratings. Set Up 40 (Sch40) describes the wall surface density. Sch40 gives a good balance of toughness and circulation capacity. It’s a typical selection for many pipe stress.

Suppliers make these tees from solid carbon steel. Carbon steel provides superb sturdiness. It deals with the requiring conditions of oil and gas transportation. The product withstands high pressure and temperature well. Butt welding is the link technique. The pipe end fits directly versus the suitable end. A weld joins them completely. This produces an extremely strong, leak-proof seal. It’s reputable for essential applications.

Readily available sizes typically range from 1/2 inch to 48 inches Small Pipe Dimension (NPS). This covers many pipe demands. The pressure ranking depends on the specific size and material grade. Constantly examine the particular score for your task. These tees collaborate with pipelines satisfying requirements like ASTM A53 or A106.

Oil and gas pipelines make use of these fittings thoroughly. They are discovered in gathering lines, transmission lines, and processing plants. Their durable construction deals with petroleum, gas, and refined products. The smooth bore reduces flow constraint. This keeps efficiency in the system. Butt weld links reduce potential leak factors. This enhances total pipeline safety and stability. Appropriate installment complying with welding treatments is necessary.

(ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines)

Applications of ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines

ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings are essential parts for building oil and gas pipes. This tee installation has 3 openings of the very same size. It attaches perpendicularly to the major pipeline run. This design permits pipeline home builders to split or combine the flow of oil, gas, or other liquids efficiently. Employees bonded these installations directly onto the pipes. Butt welding develops very solid, watertight joints. This is essential for dealing with the high pressures located inside oil and gas pipes.

The installations are made from carbon steel. Carbon steel is tough and sturdy. It takes care of the demanding conditions usual in the oil and gas sector. Sch40 refers to the wall surface density. Sch40 is a basic density. It gives a good balance between toughness and material cost. This density suffices for numerous pipe pressure scores. It resists the inner stress pressing against the pipeline wall surfaces.

These tees adhere to the ANSI B16.9 requirement. This standard defines the specific dimensions, stress scores, and testing requirements. Making use of standardized fittings makes certain compatibility. Different suppliers make parts that mesh completely. This avoids troubles throughout pipe building and construction and maintenance. It also ensures the fittings meet minimum performance and safety degrees.

Butt weld connections are favored for long-term pipes. Welded joints are very reliable. They are more powerful than threaded or flanged connections under high pressure. Welded joints also lessen potential leakage points. This boosts the total safety and honesty of the pipeline system. The smooth bore inside the suitable decreases disturbance. This helps keep flow performance and lessens disintegration inside the pipe in time.

These carbon steel Sch40 tees are widely used in celebration lines, transmission pipelines, and handling plants. They attach pipes carrying crude oil, gas, refined items, and water. Their strength and reliability make them an essential option for vital pipe facilities. The material likewise offers great resistance to corrosion in several solution environments. Appropriate material option stays essential for specific fluid types.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines

Here are 5 FAQs for ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings used in Oil & Gas Pipelines:

What exactly is this fitting? It’s a carbon steel pipe tee fitting made to the ANSI B16.9 standard. Schedule 40 (Sch40) tells you the wall thickness. “Equal Tee” means all three connection points are the same pipe size. You join it to pipes using butt welding. This creates a strong connection point to split or combine flow in a pipeline.

Why Sch40 wall thickness? Sch40 is a common standard thickness. It offers a good balance. It provides solid strength and pressure handling ability. It also keeps the fitting manageable in weight and cost. This thickness works well for many typical oil and gas pipeline pressures.

Why use butt welding? Butt welding creates a very strong, leak-proof joint. The pipe end and fitting end are carefully prepared and welded together. This method makes the connection as strong as the pipe itself. It’s reliable for high-pressure oil and gas systems. It also gives a smooth inside surface for good flow.

Where are these tees used? They are common in oil and gas gathering lines, transmission pipelines, and processing plants. You need them anywhere pipe flow must split or combine. They handle oil, natural gas, and other related fluids. They work in both onshore and offshore pipeline applications.

Why carbon steel material? Carbon steel is tough and strong. It handles high pressure well. It works at temperatures common in oil and gas pipelines. It’s also cost-effective compared to more exotic alloys. You get good performance for the money. Carbon steel resists corrosion adequately in many pipeline environments.

(ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines)

REQUEST A QUOTE

RELATED PRODUCTS

Sufficient Supply Oil Gas Pipeline and Construction Seamless Steel Pipe Petroleum Gas Line Pipe

Gas Stove Parts/gas Pipe

Hot s Seamless Carbon Steel Pipe Api 5ct Q125 Tubing And Casing Oil And Gas Pipe Casing Pipe Tube

High Pressure SCH160 Seamless Carbon Steel Pipe, ASTM A106 Grade C, Thick Wall 20-80mm

Hot Galvanized EMT Welded HDG ERW Carbon Steel Pipe 6m 12m Lengths For Container Plate Structure Application JIS Certified

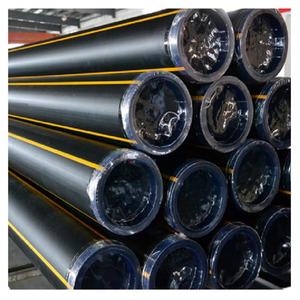

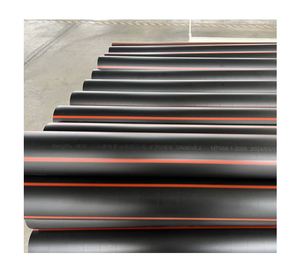

Customizable Large Caliber HDPE Plastic Tube HDPE Gas Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677