LUOYANG DATANG ENERGY TECH CO.,LTD

API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe

PRODUCT PARAMETERS

Description

Overview of API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe

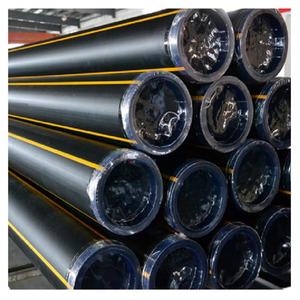

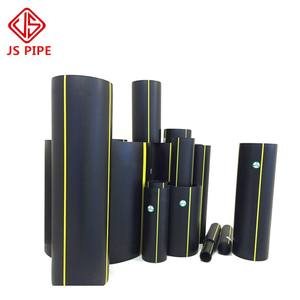

API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe)

Specifications of API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe

API 5CT K55, J55, and N80 oil casing pipes are important for oil and gas wells. They develop the major structural wall surfaces preventing the hole from breaking down. These pipes likewise safeguard groundwater from contamination. They handle the immense stress and destructive fluids found deep underground.

These steel pipes fulfill strict API 5CT criteria. This makes sure regular quality and security worldwide. The qualities K55, J55, and N80 refer to the pipe’s toughness. K55 and J55 offer moderate strength. They appropriate for several standard well midsts and pressures. They provide reliable performance at an excellent worth. N80 quality is more powerful. It handles greater pressures and more requiring conditions. N80 is tougher for deeper wells or tough formations.

Usual dimensions range from 4.5 inches to over 13 inches in diameter. Wall thickness varies depending on the needed pressure rating. Pipelines come in details sizes, typically around 30 feet. They include threaded connections on both ends. These strings are precisely reduced to API requirements. This makes certain a tight, pressure-sealing fit when screwed together downhole.

The pipes are made from specific carbon or alloy steels. This steel is selected for stamina and resistance to splitting. Manufacturing entails rigorous procedures. The pipes undertake heat treatment to accomplish the needed strength and strength. Every length is thoroughly examined and evaluated. This includes inspecting measurements, material residential or commercial properties, and surface area quality. Hydrostatic testing verifies they hold stress without dripping. Non-destructive tests locate hidden problems. This assures the pipeline’s stability before it decreases the well.

(API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe)

Applications of API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe

API 5CT K55, J55, and N80 oil casing pipes are crucial for oil and gas wells. They form the primary framework lining the drilled opening. This protects the wellbore from collapsing. It likewise stops fluids from various underground layers mixing. These pipes securely direct oil and gas to the surface area.

These casing pipelines fulfill rigorous API 5CT standards. This guarantees top quality and reliability for challenging drilling conditions. Different qualities like K55, J55, and N80 offer specific demands. K55 and J55 pipelines are common selections. They use excellent stamina for many basic well midsts. N80 grade supplies higher stamina. It deals with greater pressure and much deeper wells much better.

Key features make these pipelines function reliably. They connect using unique threaded ends. Usual thread types include STC, LTC, and BTC. These connections produce solid, watertight seals downhole. The steel building and construction supplies great collapse resistance. It holds up versus the stress from surrounding rock and liquids. Producers also apply safety layers. This battles corrosion from saltwater and other chemicals underground.

These API 5CT casing pipes have lots of vital uses. They are the backbone for new well building and construction. Employees run them into the pierced opening and cement them in place. This produces a secure, irreversible well structure. They isolate different manufacturing areas. This lets operators manage which zones produce oil or gas. They protect groundwater sources from contamination by well liquids. They supply a safe and secure path for running tools like pumps into the well. They contain well stress securely, stopping dangerous blowouts. They are vital for both onshore and overseas boring operations. They are made use of in upright wells, directional wells, and horizontal wells. They are likewise used in well repair work and maintenance job.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe

What are API 5CT K55/J55/N80 casing pipes?

These are steel pipes. They line oil and gas wells. They keep the hole open. They stop the walls from collapsing. They protect groundwater. They guide drilling tools. They form a path for oil and gas to flow to the surface. They are made to strict API 5CT standards. This ensures reliability.

Why are K55, J55, and N80 grades important?

These letters and numbers show the steel strength. J55 and K55 are medium strength. They handle normal pressure wells. N80 is stronger. It handles higher pressure wells. N80 handles deeper wells too. Choosing the right grade is critical. The wrong grade can fail. Failure causes safety risks. Failure causes expensive repairs.

Do these pipes resist corrosion?

Basic K55/J55/N80 pipes are carbon steel. Carbon steel can rust. Rust happens in wet, salty conditions. Oil and gas wells often have these conditions. Special coatings are usually applied. Coatings fight rust. Sometimes pipes are made from special corrosion-resistant alloys. This costs more. It is needed for very corrosive wells.

How is quality ensured?

API 5CT sets tough rules. Factories must follow these rules. Pipes undergo many tests. They check the pipe size. They check the wall thickness. They test the steel strength. They test the steel hardness. They inspect the pipe surface. They look for cracks or flaws. They test pressure resistance. Certified mills make the pipes. Buyers should ask for mill certificates.

Where are these casing pipes used?

They are used for drilling oil wells. They are used for drilling gas wells. They form the well structure. They are run deep underground. They are cemented in place. Different sections of the well use different grades. Shallow sections might use J55 or K55. Deeper, higher pressure sections need N80 or stronger grades. They are essential for safe, efficient drilling and production.

(API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

of Corrugated Stainless Steel Gas Hose Pipe/gas Hose Pipe

Stainless Steel Gas Pipe lpg Cylinder Gas Filling Pipes Flexible Hose for Nitrogen Argon Carbon Dioxide Oxygen Refill Pipe

A53 1/2” To 4” Pre-Galvanized Steel Pipe Gi Round Welded Steel Pipe For Structural Purposes

DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline

China Large Diameter Full Range Of Material Customization API 5L X60 X65 X70 Welded Carbon Steel Pipe/Tube For Building Material

High Quality New Gas Pipe Gas Intake Pipe K4DQ5-1113960KS1 for Truck

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677