LUOYANG DATANG ENERGY TECH CO.,LTD

API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings

PRODUCT PARAMETERS

Description

Overview of API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings

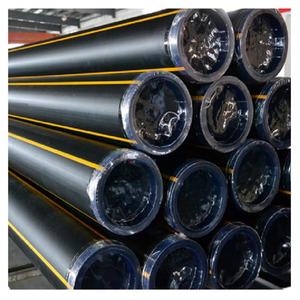

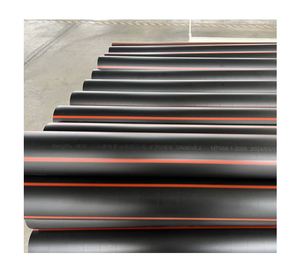

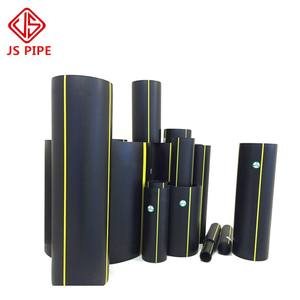

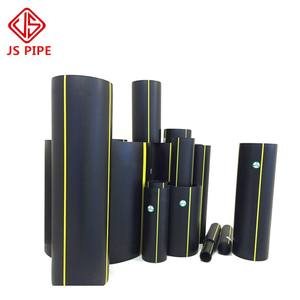

API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings)

Specifications of API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings

These API boiler tubes meet rigorous oil and gas standards. They utilize smooth steel pipelines made from ASTM A106 or ASTM A53 qualities. These materials offer excellent strength and handle high pressure well. Typical wall thicknesses are Schedule 20, 30, 40, and 80. Thicker timetables like 40 and 80 deal with a lot greater stress. Thinner timetables like 20 and 30 help reduced stress lines.

The smooth construction is necessary. Smooth tubes have no welded joints. This makes them stronger and a lot more dependable under stress. It additionally lowers powerlessness where leakages or failings could begin. This strength is crucial for boiler applications and important piping.

Inside, these tubes feature a bound PTFE (Teflon) cellular lining. PTFE is a special plastic. It supplies superb chemical resistance. This lining shields the steel pipeline from destructive fluids. Oil and gas streams frequently contain harsh components like acids, salts, or sulfur substances. The PTFE barrier stops these from harming the steel.

The smooth PTFE surface area also enhances circulation. Fluids move easier with much less rubbing inside the lined pipeline. This decreases pressure decline along the pipeline. Much less power pumps fluids through the system. The cellular lining also stops scale accumulation and contamination. Product purity stays greater.

These PTFE lined tubes fit demanding oil and gas applications. They function well for relocating harsh chemicals, hydrocarbons, and produced water. They fit pipeline systems requiring integrity and long life. The combination of strong smooth steel and protective PTFE manages hard conditions. It provides a durable service for sharing hostile media securely.

(API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings)

Applications of API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings

These API boiler tubes meet A106 and A53 standards. They come in schedules 20, 30, 40, and 80. They are smooth steel tubes. They have a PTFE lining inside. This mix is vital for oil and gas operations. It handles hard problems accurately.

The PTFE lining safeguards the steel. It quits severe chemicals from striking the pipeline wall. Petroleum and natural gas usually contain corrosive aspects. Acids and sulfur compounds are common. The lining guards the steel. This avoids leaks and failings. It expands the pipeline’s service life considerably.

These tubes carry several liquids safely. They relocate petroleum from wells. They carry gas through handling plants. They handle improved products like gas. They manage chemical ingredients utilized in production. The smooth PTFE surface area ensures excellent circulation. It reduces friction loss. It quits scale and down payments from building up inside the pipeline.

High-pressure systems make use of these tubes. Set up 80 and 40 tubes deal with substantial stress. They work well in pipelines, wellheads, and processing units. They connect pumps, shutoffs, and pressure vessels securely. Their stamina is essential for safety.

Rough materials circulation through these pipes as well. Sand and exploration mud exist in manufacturing streams. The PTFE lining withstands wear from these particles. It maintains television undamaged a lot longer than unlined pipe. This decreases maintenance costs and downtime.

Refineries and chemical plants require these tubes. They connect tools where rust is a large issue. Heat exchangers and reactors utilize them. The PTFE cellular lining protects against reactions in between liquids and the steel. This maintains item purity high. It protects against contamination.

These tubes are crucial installations. They join various components of oil and gas infrastructure. Their smooth construction makes sure no weak points. The PTFE lining gives unrivaled chemical resistance. This combination provides reputable, durable performance popular settings.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings

Here are 5 key FAQs about API Boiler Tube A106 A53 Sch 20,30,40,80 Seamless Steel Tube PTFE Lined for Oil and Gas Pipe Fittings:

What steel grades are used?

We use seamless steel tubes. These meet API standards. Common grades are A106 and A53. These grades are strong. They handle high pressure and temperature. This is essential for oil and gas systems.

What schedules are available?

We offer standard schedules. These are Sch 20, 30, 40, and 80. Schedule number means wall thickness. Higher numbers mean thicker walls. Thicker walls handle higher pressure. Sch 40 and 80 are common for demanding jobs.

Why is PTFE lining important?

PTFE lining is a plastic layer inside the steel tube. It stops chemicals from attacking the steel. Oil and gas fluids can be very corrosive. PTFE protects the pipe. This prevents leaks and failures. It makes the pipes last much longer.

Where are these pipes used?

These pipes connect equipment. They are pipe fittings. Use them in oil and gas production. Use them in refining plants. Use them in chemical transport lines. They handle corrosive fluids safely. They handle high pressure safely. They are reliable for critical systems.

Do these pipes meet industry standards?

Yes. The steel tubes meet API 5L or ASME specs. The PTFE lining meets chemical resistance standards. The final product is built for oil and gas use. Always check the specific standards for your project.

(API Boiler Tube A106 A53 Sch 20,30 40 80 Seamless Steel Tube PTFE Lined For Oil And Gas Industry Pipe Fittings)

REQUEST A QUOTE

RELATED PRODUCTS

9mm PVC Flexible High Pressure LPG Propane Butane Gas Hose Pipe 50m Smooth Surface Easy to Use Plastic Tubes

of Corrugated Stainless Steel Gas Hose Pipe/gas Hose Pipe

High-Quality Stainless Steel Gas Pipe OEM & Bulk Supply

Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline

4 Size Fuel Line Hose Petrol Tubing Common ForWeedeater Trimmer Chainsaw Blower Gasoline Pipe Petrol Pipe

Factory Hot Dip Gi Seamless Galvanized Pipe Sch 40 Erw Gi Iron Tube Welded Gi Steel Pipe/Tube For Construction

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677