LUOYANG DATANG ENERGY TECH CO.,LTD

ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe

PRODUCT PARAMETERS

Description

Overview of ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe

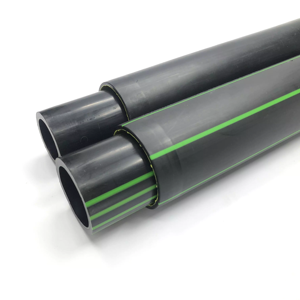

ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe)

Specifications of ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe

These pipes deal with demanding work. They are smooth carbon steel pipelines. This implies no welded seams exist. The material is solid and reputable. ASTM A106, A53, and API 5L control their production. These criteria make certain top quality and efficiency. Set Up 40 (Sch40) defines the wall surface density. This thickness offers excellent stress handling. It also offers strong toughness. The pipelines are hot-dipped galvanized. They get dipped in molten zinc. This creates a tough, adhered coating. The zinc shields the steel underneath. Rust and rust face solid resistance. The coating dramatically prolongs pipeline life. It works well in challenging settings. Outside direct exposure is not a problem. Moisture call is also managed.

The pipe size array is wide. Typical dimensions run from 1/8 inch to 24 inches. Larger sizes are commonly offered. Nominal Pipe Dimension (NPS) marks the size. The actual outside size remains repaired. The wall surface thickness changes per schedule. Sch40 is a common, moderate wall choice. It balances flow capability with toughness. Carbon steel comprises the base product. It uses good mechanical homes. Formability and weldability are useful. The hot-dip process coats inside and outside. This offers full defense. The finish is typically dull gray. It may show spangles sometimes.

These pipelines relocate fluids efficiently. Water supply use them frequently. Oil and gas transportation is common. Heavy steam lines are one more application. Architectural uses happen as well. They fit plumbing and commercial jobs. Building and construction sites rely upon them. The galvanizing stops corrosion quickly. Maintenance requires decline considerably. The seamless style stays clear of weak points. Stress rankings remain high. This mix is cost-effective with time. Toughness is an essential benefit.

(ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe)

Applications of ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe

These pipes are smooth carbon steel pipes. They meet criteria like ASTM A106, ASTM A53, and API 5L. They are Sch40 wall thickness. They have a hot dipped galvanized covering. This finishing is zinc. The zinc safeguards the steel from corrosion. This makes them last much longer outdoors and in wet areas.

Individuals make use of these pipelines in numerous areas. They bring water in buildings and communities. They relocate air in home heating and cooling systems. They take care of vapor in factories. They are good for oil and gas also, specifically the API 5L pipes. API 5L establishes guidelines for oil and gas pipe.

The smooth building is essential. There is no bonded joint. This makes the pipe very strong all around. It holds high pressure well. It deals with anxiety better than bonded pipe. This is crucial for security in gas lines or vapor lines.

The Sch40 wall thickness prevails. It offers a good equilibrium. The pipe is strong enough for numerous work. It is not too hefty or as well expensive. It benefits water pressure in homes. It benefits commercial stress too.

The warm dipped galvanizing is essential. The pipeline obtains dipped in molten zinc. This bonds the zinc to the steel snugly. It produces a tough barrier. This obstacle fights corrosion and rust. It secures the pipeline from weather, dirt, and moisture. This makes the pipeline good for exterior use. It’s good for underground use. It’s good in manufacturing facilities where chemicals might be existing.

You see these pipelines bring water under streets. They create scaffolding on structures. They relocate gas safely. They sustain structures. They operate in power plants. They are in chemical plants. They are trusted. They are strong. They withstand rust. They take care of pressure. They are a relied on selection for laborious.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe

What materials are these pipes?

These pipes are carbon steel. They are seamless. The pipes meet ASTM A106, A53, and API 5L standards. Schedule 40 (Sch40) refers to their wall thickness. They are coated using hot-dip galvanizing. This means they are dipped in molten zinc.

What pressure can they handle?

Sch40 pipes have thick walls. This makes them strong for pressure. The exact rating depends on the pipe size and the specific standard. They are suitable for many high-pressure systems. Always check the pressure chart for your exact pipe size and standard.

Why use hot-dipped galvanizing?

The zinc coating fights rust. It protects the steel from corrosion. Hot-dipping gives a thick, bonded layer. This coating lasts a long time. It is especially good for outdoor use or wet environments. It prevents the steel from rusting quickly.

Where are these pipes typically used?

People use them in many industries. Common uses include water lines and oil and gas transport. They work for structural applications and in factories. They are good for fencing and construction projects. The galvanizing makes them ideal for exposed locations or places needing corrosion resistance.

What’s the difference between ASTM A106, A53, and API 5L?

These are different standards. ASTM A53 covers both welded and seamless pipe, mainly for mechanical and pressure uses. ASTM A106 is specifically for seamless pipe used at high temperatures, like in power plants or refineries. API 5L covers line pipe used to transport oil and gas. All three standards can include seamless, carbon steel pipe like Sch40. The exact chemical makeup and testing can vary slightly between them. Choose the standard based on your project’s specific needs.

(ASTM A106 A53 API 5L Seamless Carbon Steel Pipe Sch40 Hot Dipped Galvanized Steel Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

High Accuracy And Longer Warranty Mass Flow Meter LPG Gas Flow Meter

China Top Factory Supply High Quality Low ASTM A53 A106 Gr.B Sch40 Sch80 Seamless Carbon Steel Pipe Tube For

UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes

API X42 Gas Oil Tube Ms Round Low Carbon Pipe Black Iron Used for Petroleum Pipeline Seamless Steel Pipe

Plastic High Pressureg Gas Hose Pipe Pvc lpg Pipe Pneumatic Hose

Factory Direct Large Diameter SSAW Carbon Welded Steel Pipe With Pvc Coated Iron or 3PE For Oil and Gas Industry

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677