LUOYANG DATANG ENERGY TECH CO.,LTD

ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe

PRODUCT PARAMETERS

Description

Overview of ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe

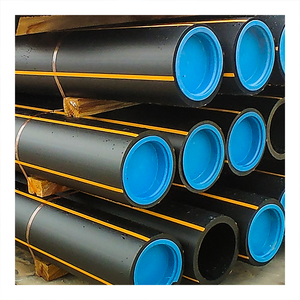

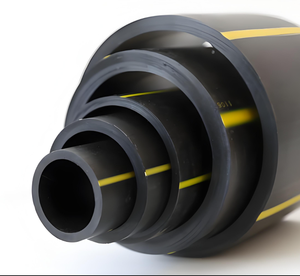

ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe)

Specifications of ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe

This product covers hot rolled A53 tubes with hot dip galvanizing. These are smooth steel pipelines meeting different international requirements. Key product qualities include ASTM ASME A106 Gr.B, A53 Gr.B, P235GH TC1, Q345C, and Q195. Popular dimensions are 20 inch, 18 inch, and 8 inch diameters. The warm rolling procedure develops the pipe from heated steel billets. This approach guarantees good dimensional precision and a smooth surface area coating. Seamless construction implies no bonded seams along the pipe length. This design offers superior toughness and dependability under stress. It likewise reduces powerlessness vulnerable to leaks or failing.

Hot dip galvanizing (HDG) is a critical action. The completed pipe obtains submerged in liquified zinc. This produces a thick, adhered zinc coating over the whole surface. The zinc layer serves as a difficult barrier against deterioration. It shields the steel from rust triggered by wetness, chemicals, and weather. This makes the pipe suitable for exterior use or severe settings. The finish additionally offers good abrasion resistance. These pipelines handle high stress and temperature level well. Various grades fit various requirements. A106 Gr.B prevails for high-temperature solution. A53 Gr.B is extensively utilized for general piping. P235GH TC1 is for stress purposes. Q345C provides greater toughness. Q195 is a standard carbon steel grade.

The available sizes (20″, 18″, 8″) fulfill typical job needs. These pipes serve numerous markets. They transfer water, oil, gas, vapor, and other fluids. You discover them in building and construction for structural supports and scaffolding. Manufacturing plants utilize them for machinery and process lines. Infrastructure jobs rely on them for utility lines and piling. Their smooth nature and zinc finishing make certain long life span. They minimize maintenance prices significantly. This combination provides a trustworthy, durable piping solution. Select the certain quality and dimension based upon your job’s pressure rating, temperature level, and environmental problems.

(ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe)

Applications of ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe

These steel pipes satisfy ASTM and ASME requirements. They consist of grades like A106 Gr.B, A53 Gr.B, P235GH, TC1, Q345C, Q195. Common dimensions are 20 inch, 18 inch, 8 inch. They are made by warm rolling. Some pipes are smooth. Lots of get a hot dip galvanized finishing. This zinc layer fights rust effectively.

These pipes are strong. They deal with high stress well. They resist warm additionally. This makes them very reputable. Industries require pipelines like this daily.

Oil and gas business use them thoroughly. They benefit relocating crude oil. They help relocating natural gas. They work for improved products too. Both over ground and buried lines utilize them. Their stamina is vital for safety.

Nuclear power plant require these pipelines. They bring heavy steam at heats. They lug water under pressure. Boilers and warm exchangers utilize them. A106 Gr.B and P235GH prevail here.

Building sites utilize these pipelines. They construct structural structures. They sustain structures. They support industrial devices. Q345C supplies great stamina for this. Smaller sized dimensions work for hand rails and fencing. Galvanized pipelines last much longer outdoors.

Water systems rely upon these pipelines. Municipal water supply lines use them. Wastewater treatment plants use them. The galvanized covering secures against corrosion. This makes sure clean water shipment.

Chemical plants procedure lots of materials. These pipes transportation numerous chemicals. They manage various stress and temperatures. Their trustworthy efficiency is necessary. Seamless pipelines avoid leaks better.

Manufacturing facilities set up these pipes. They belong to hydraulic systems. They belong to pneumatic systems. They move liquids and gases inside. Their longevity minimizes downtime.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe

Here are 5 FAQs about ASTM ASME A106 Gr.B A53 Gr.B P235GH TC1 Q345C Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe:

What materials are these pipes?

These pipes come in several common grades. The grades include ASTM A106 Gr.B, ASTM A53 Gr.B, EN 10216 P235GH, TC1, Q345C, and Q195. These are standard specifications for carbon steel pipes used in pressure systems and structural applications.

What sizes do you offer?

We supply these pipes in large diameters. Common sizes are 20 inch, 18 inch, and 8 inch. Other sizes within the hot rolled seamless range are typically available. Confirm the exact size you need.

Are these pipes hot rolled or seamless?

These pipes are manufactured using the hot rolled method. The hot rolled process involves forming steel at high temperatures. The result is a seamless pipe. Seamless pipes have no welded seam. They offer better strength under pressure compared to welded pipes.

What is Hot DIP coating?

Hot DIP refers to Hot Dip Galvanizing. This is a protective zinc coating applied after pipe forming. The pipe is dipped in molten zinc. The zinc bonds to the steel surface. This coating provides excellent corrosion resistance. It protects the pipe from rust in harsh environments.

Where are these pipes typically used?

These pipes serve many industrial purposes. Common uses are high-pressure fluid transport. Examples include oil and gas pipelines, steam lines, and boiler systems. They are also used for structural applications in construction. The specific grade chosen depends on the required pressure rating and service conditions.

(ASTM ASME As106gr.B As53gr.B P235gh Tc1 Q345c Q195 20 Inch 18 Inch 8 Inch Hot Rolled A53 Tube Hot DIP Seamless Steel Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe

ASTM A106 A53 GrB API 5L Gr.B Seamless Carbon Steel Pipe Casing Pipe Good Per Ton

API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

Hot Galvanized EMT Welded HDG ERW Carbon Steel Pipe 6m 12m Lengths For Container Plate Structure Application JIS Certified

Flexible Stainless Steel Corrugated Pipe, Metal Tube Coils For Water/Gas

API SPEC 5L Pipeline ISO 3183 ASME B36.10 ERW Seamless EMT Oil Tubing Pipe L80 N80 X42 Bending Cutting Welding Available

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677