LUOYANG DATANG ENERGY TECH CO.,LTD

Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding

PRODUCT PARAMETERS

Description

Overview of Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding

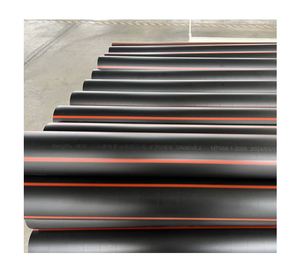

Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding)

Specifications of Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding

This Finest ing Gi Galvanized Steel Pipe is prime top quality. It’s made from solid steel. A thick zinc coating safeguards it. This zinc shield fights corrosion effectively. The pipe lasts a long time outdoors. It deals with challenging weather conveniently. You obtain reputable efficiency year after year.

The pipeline satisfies the ASTM A120 criterion. This assures top product and covering. Production utilizes the ERW technique. ERW suggests Electric Resistance Welded. An electric existing welds the joint. This develops a really strong, uniform joint. The weld is smooth inside and out. This avoids flow problems in liquids or gases.

JIS and API specifications are additionally fulfilled. This guarantees large global acceptance. You can trust its top quality around the world. The pipeline is constructed for requiring tasks. It’s a competitive selection for customers. You obtain excellent worth for your money.

Typical sizes range from 1/2 inch to 6 inches. Numerous wall surface thicknesses are readily available. Different lengths suit your project requires. The zinc covering is evenly used. This supplies regular defense all over. The surface area is smooth and clean.

This pipeline functions well in several places. Building and construction sites use it for scaffolding. Fencing jobs gain from its durability. Water system lines need its corrosion resistance. Industrial plants depend on its strength. For plumbing systems it’s a strong selection. It deals with water pressure accurately. General engineering uses it also. It’s a reliable alternative for many needs.

(Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding)

Applications of Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding

This galvanized steel pipeline uses premium. It fulfills the ASTM A120 criterion. The ERW technique makes it strong. This pipeline works well for several points. Supply of water systems utilize it widely. The zinc covering quits corrosion efficiently. This matters for exterior water lines. Building projects need trusted products. Contractors choose this pipeline for architectural supports. Its strength holds up more than time. Fencing installations locate it really beneficial. The galvanized surface area takes care of climate quickly. Rainfall and sun don’t harm it rapidly. Industrial settings require hard pipelines. Manufacturing facilities utilize it for moving liquids safely. Air compression systems frequently need it. Its smooth inside helps air circulation easily. Scaffolding needs lightweight yet strong components. This pipe fits that demand flawlessly. It’s lighter than numerous solid steel options. Transporting and putting it up is simpler. JIS and API criteria accept its high quality. This implies international acceptance for jobs. Competitive welding is an essential function. Joints hold solid without added price. Farmers use it for irrigation setups. The layer secures against dirt chemicals. It lasts lots of seasons without failing. General pipes jobs utilize it too. Its integrity makes it an usual choice. The zinc layer provides long-lasting safety. You obtain a durable product ready for hard work.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding

What exactly are galvanized steel pipes?

Galvanized steel pipes are regular steel pipes coated with zinc. This zinc layer shields the steel from rust and corrosion. Water systems, construction, and fencing often use them. The zinc makes them last much longer outdoors.

What do ASTM A120 and JIS API mean?

ASTM A120 and JIS API are quality standards. They are rules for making steel pipes. These rules ensure the pipes are strong, safe, and reliable. Our pipes meet these exact standards. Buyers trust pipes following these international rules.

Why is the ERW technique important?

ERW stands for Electric Resistance Welding. It is how we make the pipe seam. ERW is efficient and creates a very strong, smooth joint. This method produces consistent pipes. It keeps costs down without sacrificing pipe quality.

How do I know the quality is good?

We inspect every batch rigorously. We check the zinc coating thickness, the pipe strength, and the overall finish. We provide mill test certificates. These documents prove the pipes meet the ASTM and JIS specifications you require.

Why choose your pipes over others?

Our pipes combine top quality with competitive pricing. The zinc coating is thick and uniform. The ERW process ensures reliable welds. We meet strict international standards like ASTM and JIS. You get durable, long-lasting pipes that perform well.

(Best ing Gi Galvanized Steel Pipe Prime Quality ASTM A120 Gi Steel Tube ERW Technique JIS API Competitive Welding)

REQUEST A QUOTE

RELATED PRODUCTS

Made-in China Galvanized/Stainlesss/Ms Alloy Large Diameter Thick Wall Boiler Carbon Seamless Steel Tube Pipe

China Top Factory Supply High Quality Low ASTM A53 A106 Gr.B Sch40 Sch80 Seamless Carbon Steel Pipe Tube For

Galvanized Q235 Steel Tube Steam Directly Buried Leak-Proof Insulation Pipe Central Heating Drill Pipe GS Certified

Factory Yellow Natural Gas Pipe High Pressure Flexible Gas Hose Pipe

Astm A106b/a53 Gr. B Seamless Schedule 40 Carbon Steel Pipe Used For Oil And Gas Pipeline

High-Quality Stainless Steel Gas Pipe OEM & Bulk Supply

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677