LUOYANG DATANG ENERGY TECH CO.,LTD

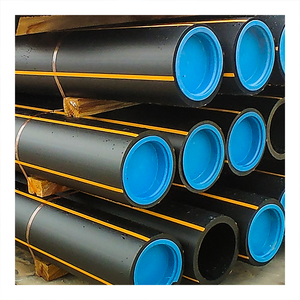

Black Polyethylene (PE) Pipe For Gas Line Use

PRODUCT PARAMETERS

Description

Overview of Black Polyethylene (PE) Pipe For Gas Line Use

Black Polyethylene (PE) Pipe For Gas Line Use is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Black Polyethylene (PE) Pipe For Gas Line Use

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Black Polyethylene (PE) Pipe For Gas Line Use)

Specifications of Black Polyethylene (PE) Pipe For Gas Line Use

This black polyethylene pipeline is for underground gas lines. It’s made from solid plastic material. This plastic is called PE. The pipe is black because it has actually carbon black included. Carbon black shields the pipeline from sunshine damages. It likewise helps the pipe last longer below ground.

The pipe comes in various dimensions. Typical sizes vary from 1/2 inch to 24 inches in diameter. The wall surface thickness is important. Thickness relates to the pipeline’s SDR number. SDR implies Standard Dimension Proportion. A reduced SDR number means a thicker wall. Thicker walls handle higher pressure. Common SDR scores consist of SDR 11 and SDR 17.6.

Stress score is key for gas pipelines. The pressure ranking depends upon the PE quality and the SDR. Usual PE qualities are PE80 and PE100. PE80 pipeline usually has a lower pressure score. PE100 pipeline has a greater pressure score. Always inspect the specific stress score for the pipeline size and quality you need. The pipeline is made for continuous gas pressure underground.

Temperature level issues as well. This pipeline functions well in chilly and moderate temperatures. The regular operating variety is from -40 ° C to 60 ° C. It stays flexible even in cold problems. This adaptability aids throughout setup. It additionally helps the pipe manage ground motion.

Quality requirements are strict for gas pipelines. This pipeline fulfills global criteria. Essential criteria consist of ISO 4437 and ISO 4427. Regional guidelines could need certain accreditations. Always validate the pipe fulfills your project’s requirements. The pipe should be significant clearly. Markings show the product grade, size, SDR, stress ranking, and supplier. Try to find these markings.

Installment needs care. The pipeline connects utilizing warm fusion methods. Butt combination and electrofusion prevail methods. Proper fusion develops a strong, watertight joint. Trained teams ought to do the installment. The pipe should be laid in a prepared trench. The trench ought to be free of sharp rocks. Bed linen material safeguards the pipe.

(Black Polyethylene (PE) Pipe For Gas Line Use)

Applications of Black Polyethylene (PE) Pipe For Gas Line Use

Black polyethylene pipeline functions well for below ground gas lines. Its major benefit is withstanding rust. Steel pipelines corrosion underground gradually. PE pipe doesn’t rust. This indicates it lasts much longer. It remains solid for years. This makes it an excellent long-term choice.

Installers like PE pipe because it flexes easily. It does not require several installations. Workers can route it around obstacles like rocks or origins. This conserves time and labor costs during installation. Less joints additionally imply less potential leak factors.

The pipeline links using warmth blend. Workers melt the pipeline finishes with each other. This creates a permanent, seamless joint. The joint is as strong as the pipeline itself. It won’t leak. There are no gaskets or mechanical parts to stop working later. This fusion method is extremely reputable for gas systems.

Gas business use this pipeline extensively. It brings gas from the primary line to houses. It offers apartment buildings and organizations too. Longer sections attach bigger distribution networks. It handles different gas stress safely.

This black PE pipe satisfies rigorous safety and security criteria. It adheres to ASTM D2513 and similar regulations. These guidelines guarantee the product is safe for fuel gas. The pipeline is difficult. It takes care of ground movement and heavy loads well. It will not fracture easily.

The smooth inside surface area aids gas flow successfully. This lowers stress loss over distance. Gas relocations freely without added pumping. This keeps operating costs lower. The pipeline is likewise light-weight. Transferring and handling it is much easier than steel pipeline.

Underground problems are rough. Moisture, chemicals, and changing dirt exist. PE pipeline stands up to these well. It doesn’t degrade like some materials. Its performance remains constant. Utilities trust it for secure, dependable gas shipment.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Black Polyethylene (PE) Pipe For Gas Line Use

Why choose black PE pipe for gas lines?

PE pipe is certified for gas. It’s tough and flexible.

Is PE pipe safe for gas?

Yes. It’s made for gas use. It resists corrosion and leaks well. Metal pipes can rust. PE pipe won’t. It handles gas safely over time.

How is installing PE pipe different?

PE pipe uses heat fusion welding. Workers melt the pipe ends together. This makes a solid, permanent seal. It’s different from threaded metal pipes. Fusion joints are very strong and leak-proof. No joints are needed for long runs.

What temperatures can PE pipe handle?

PE pipe stays flexible in cold weather. It won’t become brittle. It handles temperatures down to -70°F. High heat is a problem. Avoid temperatures above 140°F. Protect it from direct sunlight long-term.

How long does PE pipe last underground?

PE pipe lasts a long time underground. It resists chemicals and corrosion. It won’t rot or break down like some materials. Expect 50 years or more of service life. Proper installation matters.

Can PE pipe connect to existing metal pipes?

Yes. Special transition fittings are used. These fittings join PE pipe to steel or other metals safely. Trained professionals must do this work. It ensures a secure, leak-free connection.

(Black Polyethylene (PE) Pipe For Gas Line Use)

REQUEST A QUOTE

RELATED PRODUCTS

Pvc lpg Gas Pipe

Factory Direct PE Plastic Gas Pipe

Astm A53 A106 Api 5l Schedule 40 Ms 114Od 30Mm Thickness Small Diameter Bi 1Kg Seamless Steel Pipe Tube of Carbonsteel Pipes22

Galvanized Q235 Steel Tube Steam Directly Buried Leak-Proof Insulation Pipe Central Heating Drill Pipe GS Certified

All Kinds of Diameter Hdpe Natural Gas Pipe Factory Good Sdr11 Pe Pipe with Yellow Orange Line Strips for Natural Gas

Good s in Europe Market Api 5l X70 X52 Lsaw Pipe Din 2448 St37 Carbon Steel Pipe Tube Petroleum Gas Oil Seamless Tube

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677