LUOYANG DATANG ENERGY TECH CO.,LTD

DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline

PRODUCT PARAMETERS

Description

Overview of DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline

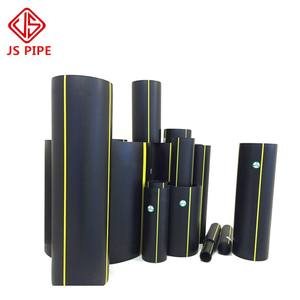

DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline)

Specifications of DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline

This DN200 to DN3800 thick steel tube is spiral bonded pipeline for demanding oil and gas pipe projects. It’s made from solid carbon steel. The pipeline size spans from 200 millimeters right as much as 3800 millimeters. The typical instance given is 609 mm. This size range covers lots of pipeline needs.

Wall thickness is significant. It takes care of high pressure liquid transport efficiently. The steel used is top quality carbon steel. This material offers superb strength. It additionally offers good weldability. These homes are crucial for pipeline honesty.

The pipeline uses the SSAW method. SSAW represents Spiral Submerged Arc Welded. The steel strip is created into a spiral shape. Then a submerged arc welds the joint continually. This produces a trusted, long-length pipeline. The helical joint disperses stress and anxiety well.

The pipeline exterior often obtains protective finish. Usual finishes consist of FBE or 3LPE. These coatings protect against rust. This is vital for underground or underwater pipes. The pipe interior might additionally be covered. This depends on the specific liquid being moved.

Production follows stringent standards. Typical requirements are API SPECIFICATION 5L, GB/T 9711, or ISO 3183. These make sure worldly top quality and weld performance. The pipeline goes through extensive testing. This includes hydrostatic pressure examinations. It also includes non-destructive assessment like ultrasonic screening. Dimensional checks are mandatory. This guarantees the pipe satisfies specifications.

This SSAW pipeline is built for long-distance transmission. It takes care of crude oil effectively. It additionally transports gas securely. Its big sizes are reliable for main pipeline paths. The thick walls manage high operating pressures. The spiral bonded design offers inherent stamina benefits.

(DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline)

Applications of DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline

These SSAW spiral welded steel pipes cover a large dimension variety. DN200 to DN3800 suggests they fit lots of pipe tasks. The 609mm carbon steel pipe is an usual size. The helical seam weld is key. This spiral style makes the pipe solid. This stamina is important for oil and gas transportation. Buried pipes encounter ground stress. They likewise take care of the product inside under pressure. Thick steel wall surfaces are crucial. They prevent leakages and ruptures securely. High-pressure oil or gas requirements this sturdiness.

These pipelines are developed for long-distance lines. They bring crude oil from areas. They carry gas to cities. The spiral weld holds up well. It handles the anxiety of pumping stations. The steel quality is chosen thoroughly. It resists corrosion from the product. It likewise withstands dirt conditions. Big sizes like DN3800 move huge volumes. This is critical for primary transmission lines. Smaller sized diameters offer branch lines.

Installation is efficient. The spiral joint supplies versatility. This assists somewhat during flexing over terrain. It preserves pipe honesty. The thick wall manages high operating pressure. This stress presses the oil or gas far ranges. Strength is non-negotiable for security. Pipe failures create environmental damages. They also interrupt supply. These pipelines give reputable containment. They maintain the product streaming safely. Longevity is important underground. Fixing a hidden pipe is costly. It triggers major downtime. Long life span is anticipated. These pipes provide that performance. They develop the backbone of energy infrastructure. Their role is basic.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline

What sizes do these spiral welded pipes cover?

Our pipes range from DN200 to DN3800. This means diameters start at roughly 200 millimeters. They go up to a very large 3800 millimeters. The 609 mm size is a common option in this range. We offer various wall thicknesses to meet different pressure needs.

How strong and thick are these pipes?

These pipes use thick carbon steel. The steel grade and wall thickness give high strength. This strength handles the high pressure inside oil and gas lines. It also supports the pipe weight underground or underwater. Thicker walls are used for tougher jobs.

Do these pipes resist rust and corrosion?

Yes, they get special protective coatings. Common coatings include epoxy or polyethylene. This layer shields the steel from water, soil, and chemicals. Good coating stops leaks and makes the pipeline last much longer. Proper coating is vital for safety.

Where exactly are these pipes used?

Their main use is moving oil and natural gas. They work for long-distance pipelines across land. They also work underwater for offshore projects. The spiral weld design makes them strong and reliable for these jobs. They carry raw materials safely over miles.

What quality standards do they meet?

We make pipes to strict international standards. Key standards include API 5L and ISO 3183. These rules control the steel quality, welding, and testing. Every pipe undergoes checks like hydrostatic pressure tests. This ensures they perform reliably for years.

(DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline)

REQUEST A QUOTE

RELATED PRODUCTS

Stainless Steel Gas Pipe lpg Cylinder Gas Filling Pipes Flexible Hose for Nitrogen Argon Carbon Dioxide Oxygen Refill Pipe

Universal Car Fuel Hose Oil Gas Cooler Line Pipe Tube Pipe

High-Quality Stainless Steel Gas Pipe OEM & Bulk Supply

A53 1/2” To 4” Pre-Galvanized Steel Pipe Gi Round Welded Steel Pipe For Structural Purposes

ANSI B16.9 Carbon Steel Sch40 Equal Tee Butt Welding Pipe Fittings For Oil & Gas Pipelines

16 Inch 24 Inch 30inch Schedule 40 Carbon Steel Seamless Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677