LUOYANG DATANG ENERGY TECH CO.,LTD

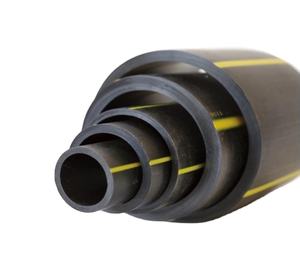

Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes

PRODUCT PARAMETERS

Description

Overview of Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes

Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes)

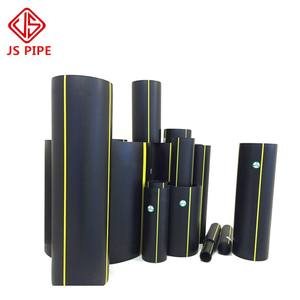

Specifications of Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes

Long lasting PE plastic gas pipelines withstand corrosion properly. They deal with gas and gas securely underground or above. This product doesn’t rust or rot like steel pipelines. It stands up to many dirt chemicals too. This means a longer life with less upkeep.

These pipes are really challenging. They withstand splits and impacts well. They bend a little without damaging. This makes setup less complicated, particularly around challenges. Workers can commonly utilize simpler excavating methods. That conserves time and money on projects.

The pipe joints fuse with each other making use of warm. This creates a seal as strong as the pipe itself. Leaks at the joints end up being very unlikely. This fusion approach is reliable for keeping gas secure inside the pipe.

PE plastic functions well in various temperatures. It performs from chilly winter seasons to warm summertimes. The material doesn’t become brittle in freezing weather. It stays strong under pressure over time. These pipes last for decades underground.

Setup is typically faster than with metal pipes. The pipelines are lighter, making them easier to take care of and carry. Much less heavy tools is often needed on site. This decreases general project expenses considerably. The smooth inside surface area assists gas circulation successfully. This reduces stress loss over cross countries.

These pipes are a clever selection for many gas systems. They work for domestic communities, business structures, and commercial sites. Energies trust them for secure, dependable gas delivery. Building contractors value the less complicated setup process. Homeowner take advantage of the long life span and marginal upkeep. The pipes fulfill stringent security standards for gas transportation. They supply a trustworthy solution for contemporary gas circulation requirements.

(Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes)

Applications of Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes

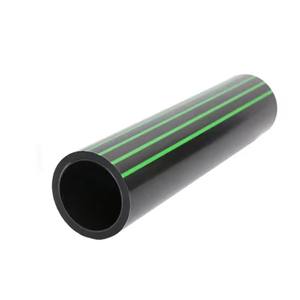

PE gas pipes made from durable polyethylene plastic fix big problems underground. Metal pipelines corrosion over time. Rust creates leaks and expensive fixings. Plastic PE pipes don’t corrosion. They withstand deterioration flawlessly. This indicates they last much longer, commonly over 50 years securely bring gas.

These tough plastic tubes take care of stress well. They bend a little without damaging. This adaptability helps during setup. Employees can lay them conveniently around challenges like rocks or other pipes. Trenching ends up being simpler and much faster. Less digging means reduced prices for jobs.

The smooth inside surface area of PE pipe is very important. Gas flows quickly with much less friction. This reduces pumping power required. Energy cost savings add up dramatically over decades of use. Operators invest less cash relocating gas via the system.

PE pipelines function wonderful for several gas work. Cities use them for brand-new community lines and changing old steel mains. Backwoods profit too. Long runs across farms or under rivers are possible with fewer joints. Fewer joints indicate less prospective leakage points. Security boosts.

Repair service staffs likewise rely upon PE pipes. They can slip brand-new plastic liners inside old, damaged pipes without digging substantial trenches. This trenchless method solutions leaks quickly. It reduces roadway closures and disturbance for people close by. It conserves money and trouble.

Setup is uncomplicated. Areas fuse together using warm. This creates solid, seamless connections. The joints become as challenging as the pipe itself. Leakages at connection factors are very unusual. The fused sections form one continual, trustworthy line underground.

These pipes resist damage from dirt chemicals and electric currents. They do not respond like metal. This resistance makes certain regular performance time after time. It provides comfort for utility firms and communities relying on risk-free gas shipment.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes

PE gas pipes are plastic tubes made from polyethylene. Workers make the pipes using a special PE material. This material fights rust very well. Metal pipes often rust underground. These plastic pipes do not. They last much longer. The material is very tough. It bends easily without breaking. This helps during installation. Workers use heat to join pipe sections. This makes strong, leak-proof connections. These pipes carry natural gas safely underground.

What makes PE pipes good for gas?

PE pipes resist corrosion completely. Rust destroys metal pipes. Plastic pipes avoid this problem. They handle pressure well. The material is very durable. It won’t crack easily. It also resists many chemicals found in soil. This makes PE pipes reliable for gas delivery.

Why pick plastic over metal pipes?

Plastic pipes cost less over time. Metal pipes rust and need replacing sooner. Fixing broken metal pipes is expensive. Plastic pipes last 50 years or more. They need less digging for repairs. Installation is often faster too. The pipes are lighter. Workers handle them easier. This saves labor costs.

How do you install PE gas pipes?

Workers dig a trench. They lay the pipe inside. The pipe bends around curves smoothly. Workers connect sections using heat fusion. They heat the pipe ends. They press the melted ends together. This forms one solid piece. No joints can leak later. This method creates very strong seals.

How long do PE gas pipes last?

Properly installed PE pipes last decades. Studies show they work well over 50 years. The material doesn’t wear out from corrosion. Underground conditions don’t damage it. Sunlight can harm the plastic. But pipes buried underground avoid sunlight. They stay protected for a very long time.

Do PE gas pipes need special care?

PE pipes need very little upkeep. Their smooth inside surface stays clean. Gas flows easily without blockages. Workers check the pipes occasionally. They look for damage from digging or ground shifts. Mostly, the pipes just work. There is no need for special cleaning or coatings.

(Durable Corrosion-Resistant PE Material Polyethylene Gas Pipe Plastic Tubes)

REQUEST A QUOTE

RELATED PRODUCTS

S355 Weld Carbon Steel Pipe

Galvanized Steel Pipe Ssaw Steel Pipe Tube For Oil And Gas Industry

Stainless Steel Gas Pipe lpg Cylinder Gas Filling Pipes Flexible Hose for Nitrogen Argon Carbon Dioxide Oxygen Refill Pipe

High Quality API 5L ASTM Seamless Oil Pipe Gas Pipe

Hot Astm Seamless Carbon Steel Pipe/seamless Pipe Manufacture/smls Pipe

Factory Hot Dip Gi Seamless Galvanized Pipe Sch 40 Erw Gi Iron Tube Welded Gi Steel Pipe/Tube For Construction

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677