LUOYANG DATANG ENERGY TECH CO.,LTD

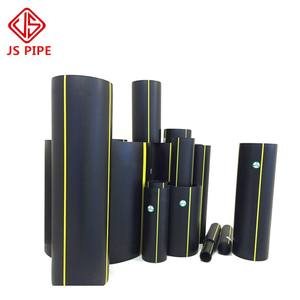

Factory Direct PE Plastic Gas Pipe

PRODUCT PARAMETERS

Description

Overview of Factory Direct PE Plastic Gas Pipe

Factory Direct PE Plastic Gas Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Factory Direct PE Plastic Gas Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Factory Direct PE Plastic Gas Pipe)

Specifications of Factory Direct PE Plastic Gas Pipe

Manufacturing Facility Direct PE Plastic Gas Pipe Specifications

This pipeline is polyethylene plastic. It is made for gas systems. Our factory sells it straight. This conserves you money. You obtain the same quality as big brands.

The material is high-density polyethylene. People call it HDPE. It is solid and adaptable. It resists splits effectively. Chemicals do not easily damage it. It deals with impacts better than old steel pipelines. Rust and rust are impossible. This makes it last a long time underground.

Dimensions are basic. Usual diameters are 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 90mm, and 110mm. We have others too. Pipelines come in coils or straight sizes. Coil sizes are normally 50 meters or 100 meters. Straight sizes are 6 meters or 12 meters. Inquire about particular dimensions you require.

Pressure ratings are important. Requirement ratings are PN6 (6 bar) and PN10 (10 bar). Some sizes go higher. Select the score for your system pressure. Temperature array is vast. It works from -20 ° C to +40 ° C safely. Brief peaks up to +60 ° C are alright.

Setup is straightforward. Utilize the butt fusion technique. This thaws the pipeline ends with each other. It develops a long-term, leak-proof joint. The pipe is smooth inside. Gas flows conveniently. This decreases rubbing loss. It conserves power in time.

We adhere to rigorous quality guidelines. Manufacturing meets ISO 4437 criteria. Every batch obtains tested. We check dimensions, strength, and pressure resistance. Shade is typically yellow or black with yellow red stripes. This shows it’s for gas. We supply certificates.

(Factory Direct PE Plastic Gas Pipe)

Applications of Factory Direct PE Plastic Gas Pipe

Manufacturing facility direct PE plastic gas pipe supplies dependable fuel transport for lots of situations. It’s the top selection for underground gas systems. This challenging plastic pipe deals with gas and lp securely. Its versatility makes installment easier in tight spots or unequal ground.

You see this pipe anywhere in gas distribution networks. It connects transmission lines to communities. It connects specific homes and businesses to the major supply. The pipe brings gas right to devices like stoves, heating systems, and boilers safely. Industrial websites depend on it as well, feeding fuel to factories, power plants, and large centers requiring constant gas flow.

Trick benefits drive its prevalent use. PE pipeline stands up to rust completely. Steel pipelines corrosion with time. This plastic option prevents that problem totally. It lasts years underground without degeneration. This long life suggests large savings on substitutes and excavating prices later on.

Installment is one more significant and also. Educated teams fuse sections with each other using heat. This produces seamless, watertight joints stronger than the pipe itself. The pipe flexes conveniently around challenges. This reduces the requirement for added fittings. Less joints imply fewer potential leak factors. Its lightweight makes taking care of a lot easier than steel pipelines. Employees move and install it faster.

The material endures ground movement well. It flexes somewhat without breaking during soil changes or minor earthquakes. This prevents ruptures and keeps gas had. Trenchless methods commonly make use of PE pipe. Teams can draw it with the ground under roads or rivers without significant digging. This minimizes interruption in active locations.

PE pipe offers a risk-free, long lasting, economical option for getting gas where it’s needed. Its performance makes it necessary for modern gas facilities tasks big and small.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Factory Direct PE Plastic Gas Pipe

PE Plastic Gas Pipe: Your Top 5 Questions Answered

What makes PE pipe safe for gas?

PE plastic pipe is specially made for gas. It’s designed tough. This pipe resists corrosion completely. It won’t rust or rot underground. Leaks are very unlikely with proper installation. Safety is the top priority.

How long does this pipe last?

Factory direct PE gas pipe lasts a very long time. It handles underground conditions well. You can expect reliable service for decades. Its resistance to corrosion and chemicals means fewer problems. It saves money over time.

How is this pipe installed?

Installation uses heat fusion. Workers join sections with special heating tools. This melts the pipe ends together. The result is a strong, leak-proof joint. The method is reliable and proven.

What temperatures can it handle?

PE gas pipe works in most weather. It stays flexible in cold temperatures. It won’t become brittle. It also handles moderate heat well. Check the specific pipe rating for exact limits. It’s suitable for most climates.

Why buy factory direct?

Buying direct cuts out extra costs. You pay less than buying through middlemen. You get the same high-quality pipe. You deal directly with the source. This means better value for your project.

(Factory Direct PE Plastic Gas Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

China Hot- 1″ 2″ 3″ 4″ 5″ 6″ 8″ 10″ Sch10/20/30/40 Astm A106/a53/a519/api 5l Carbon Seamless Carbon Steel Pipe/tube

Factory Hot Dip Gi Seamless Galvanized Pipe Sch 40 Erw Gi Iron Tube Welded Gi Steel Pipe/Tube For Construction

Customized s Carbon Steel Seamless Pipe In Liaocheng Hot C N Seamless Carbon Steel Pipe 2

DX54D Non-Oiled Water-gas Seamless Welding Non-galvanized Ventilation System air Duct Seam Welding Steel Pipe Spiral Seam Tube

Competitive s Astm A106 Grade B Hot Rolled Steel Tube Carbon Seamless Steel Pipe Welded Steel Pipes

High Quality New Gas Pipe Gas Intake Pipe K4DQ5-1113960KS1 for Truck

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677