LUOYANG DATANG ENERGY TECH CO.,LTD

Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines

PRODUCT PARAMETERS

Description

Overview of Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines

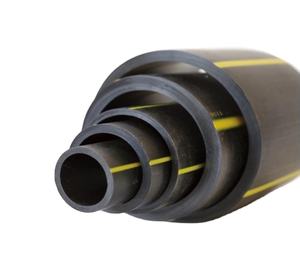

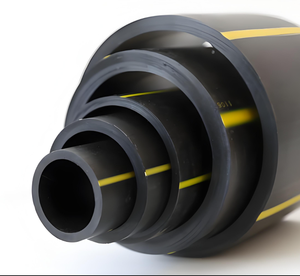

Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines)

Specifications of Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines

Hot rolled seamless steel pipe is essential for transporting oil and natural gas. These pipes reliably move fluids under high pressure. They are made by piercing a solid steel billet. The steel is heated and rolled. This process creates a pipe without any welded seam. The lack of a weld seam is critical. It makes the pipe stronger and more leak-proof. This strength is vital for high-pressure pipelines.

These pipes meet strict international standards. Key standards include API 5L and ASTM A106. API 5L covers line pipe for oil and gas transmission. ASTM A106 covers seamless carbon steel pipe for high-temperature service. Pipes follow grades like B, X42, X52, X60, X65, X70, and higher. The grade indicates the minimum yield strength. Higher grades offer greater strength.

Pipe dimensions vary widely. Common outside diameters range from 1/2 inch to 24 inches or larger. Wall thicknesses are also diverse. Thicker walls handle higher pressures. Manufacturers produce pipes in specific schedules. Schedule 40, 80, and 160 are common. Each schedule has defined wall thicknesses. The pipe length is usually random, between 6 meters and 12.5 meters. Longer lengths are possible.

The steel itself has specific properties. Yield strength and tensile strength are crucial. Yield strength is the stress point where permanent deformation starts. Tensile strength is the maximum stress the pipe can handle before breaking. Elongation measures ductility. It shows how much the pipe can stretch before fracturing. Hardness testing ensures the pipe surface is tough enough. Impact testing confirms performance in cold temperatures.

Chemical composition is tightly controlled. Elements like carbon, manganese, silicon, phosphorus, and sulfur have strict limits. Chromium, molybdenum, nickel, copper, vanadium, and other elements may be added. These elements enhance strength, toughness, and weldability. Controlling chemistry ensures consistent performance.

Quality control is rigorous. Every pipe undergoes hydrostatic testing. This test checks for leaks under high water pressure. Non-destructive testing like ultrasonic or electromagnetic inspection finds hidden flaws. Dimensional checks confirm correct size. Visual inspection looks for surface defects. Mill test certificates provide proof of compliance. These certificates list all test results and chemical analysis.

(Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines)

Applications of Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines

Hot rolled seamless steel pipes are vital for moving oil and natural gas over long distances. Their seamless nature means no welded seams running down the pipe. This makes them much stronger. They handle extreme pressure deep underground or underwater. Oil and gas pipelines face tough conditions. These pipes resist cracking better than welded types. That’s crucial for safety and preventing leaks. The smooth inside surface helps oil and gas flow easily. This reduces friction loss during transport. It saves energy pumping the fluids. These pipes also fight rust well. Oil and gas can be corrosive. Good corrosion protection extends the pipeline’s life. This lowers maintenance costs over time.

Beyond oil and gas, hot rolled seamless pipes serve other critical transport jobs. They carry steam efficiently in power plants. High heat and pressure demand reliable pipes. Chemical plants rely on them too. They safely move aggressive chemicals needing strong, leak-proof containment. Water treatment facilities use these pipes. They transport large volumes of clean water or manage wastewater flows. Their strength and durability are key here. Construction projects use them for structural supports. They form sturdy frameworks in buildings and bridges. The manufacturing sector needs them for machinery. They transport fluids like hydraulic oil under high pressure inside factory equipment. City heating systems depend on these pipes. They distribute hot water or steam to homes and businesses reliably.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines

Hot Rolled Seamless Steel Pipes are vital for oil, natural gas, and other pipeline systems. People often ask these questions. What exactly is a hot rolled seamless steel pipe? It’s a pipe made from solid steel without any welding seams. Manufacturers heat a steel billet until it’s soft. Then they pierce it and roll it into a hollow tube shape. This method ensures the pipe has no weak joints.

Why choose these pipes for oil and gas transport? They handle high pressure very well. Seamless pipes won’t split at welded seams. That makes them safer for carrying flammable materials over long distances. They resist leaks better than welded pipes.

What are the main benefits? These pipes are extremely strong. They cope with extreme temperatures underground or underwater. They last longer in harsh conditions like deserts or offshore sites. Maintenance costs drop because they don’t fail easily.

How do you make hot rolled seamless pipes? Start with a solid steel cylinder called a billet. Heat the billet to over 2,000 degrees Fahrenheit. Force a hole through its center to create a hollow shell. Stretch and shape the shell using rollers. Cool the pipe slowly to lock in its toughness.

What standards apply? Common ones are API 5L for oil and gas lines. ASTM A106 covers high-temperature service pipes. ASTM A53 is for general use. These rules check the pipe’s strength, size, and safety. Factories test every batch to meet these requirements.

(Hot Rolled Seamless Steel Pipe for Oil and Natural Gas and Other Fields of Transportation Pipelines)

REQUEST A QUOTE

RELATED PRODUCTS

API 5 CT K55 J55 N80 Oil And Gas Delivery Petroleum Oil Casing Pipe

High Quality New Gas Pipe Gas Intake Pipe K4DQ5-1113960KS1 for Truck

API 5l X42 X50 Line Pipe Steel Pipe with 3 Layer Polyethylene Coating A53 A106 Gr.b Pipes for Oil and Gas Transmission Pipeline

Auto Conversion Cng Gas Steel Pipe/Copper Pipe Carbon Steel Cng lpg Autogas High Pressure Tube

Large Schedule For Oil And Gas Pipeline 40 ASTM A53 Gr. B ERW Carbon Steel Pipe

API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677