LUOYANG DATANG ENERGY TECH CO.,LTD

Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines

PRODUCT PARAMETERS

Description

Overview of Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines

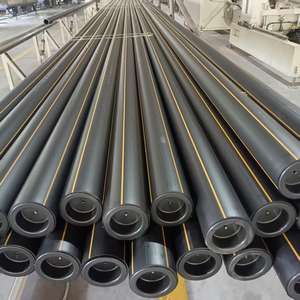

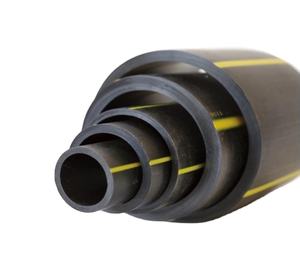

Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines)

Specifications of Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines

These big size steel pipes move gas securely over fars away. They are developed difficult for requiring pipe work. Usual qualities include L245, L360, L415. You likewise see them called X42, X52, X60. These names tell you the steel’s stamina degree. Greater numbers imply more powerful steel. L415/X60 is stronger than L245/X42.

The pipelines fulfill the API 5L spec. This is the vital global standard. It makes sure quality and efficiency. Diameters are big, frequently over 24 inches. Some pipes are wider than your arm span. Wall thickness varies dramatically. Thicker walls take care of higher pressures. Thinner wall surfaces work for lower stress. The exact thickness depends upon the pipeline’s layout pressure.

The steel itself is solid and durable. It stands up to splitting well. Good strength is crucial, especially in cool areas. Pipelines should bend without damaging throughout installation. They must likewise resist internal pressure forces. Deterioration security is crucial. Pipes normally obtain special layers on the surface. Fusion-bonded epoxy (FBE) is common. Some pipes get additional security like concrete weight covering. This helps for undersea pipes.

These pipes connect areas of major gas transmission lines. They develop the major arteries relocating gas from fields to cities. Building teams weld them with each other on-site. They are made use of onshore and offshore. Integrity is non-negotiable. A failure implies huge troubles. Every pipe undergoes stringent checks. Mills test the steel strength and durability. They examine measurements meticulously. They examine for surface area problems. This makes certain just great pipelines ship out. Pipe drivers depend on these large size tubes. They are vital for risk-free, efficient gas delivery tasks.

(Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines)

Applications of Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines

Gas pipes require solid, trustworthy pipes to move gas securely over cross countries. Big size steel tubes are important for this work. They lug significant quantities of gas effectively from sources to cities and markets. Pipes like L245, L360, L415, X42, X52, and X60 prevail choices for these major transmission lines.

The particular pipe grade used relies on the pipeline’s demands. L245 or X42 pipes benefit lower stress systems or much shorter lines where the needs are much less extreme. They use strong stamina at a practical cost. For most major cross-country pipelines, medium grades like L360 or X52 are the criterion. They handle greater operating stress well. This makes them suitable for relocating huge gas volumes across states or regions.

Where pipelines face the hardest problems, higher qualities like L415 or X60 are needed. These pipes handle really high stress. They are additionally essential for pipes crossing challenging surface like hills, quake zones, or deep underwater. Their extra stamina ensures safety and stability in these tough areas.

Steel is the preferred product for these huge pipelines. It offers the necessary toughness and resistance to breaking under pressure. These pipelines are constructed to last for years, resisting deterioration and the consistent tension of consisting of pressurized gas. Their huge diameter is vital. Bigger pipes simply relocate a lot more gas. This reduces the need for extra pumping stations over long courses, conserving money and complexity.

Designers choose the specific pipe grade after mindful research. They check out the gas stress required, the range the pipeline will cover, and the atmosphere it passes through. Whether it’s a brand-new pipe job or replacing old sections, these large diameter L and X grade steel pipes create the foundation of safe, effective gas shipment networks worldwide. They bring energy from remote areas directly to homes and nuclear power plant.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines

Natural Gas Pipeline Steel Tubes: Key Questions Answered

Customers often ask about large steel pipes for natural gas lines. These pipes carry gas long distances safely. Here are five common questions and their answers:

What do L245, L360, L415, X42, X52, X60 mean?

These letters and numbers show the steel’s strength grade. Higher numbers mean stronger steel. L grades follow international standards. X grades follow American standards. L360 equals X52 in strength. L415 equals X60. You choose the grade based on pipeline pressure needs.

Why are large diameters used?

Big pipes move more gas efficiently. They reduce the number of pumping stations needed over long distances. This saves money over time. Common large diameters are 20 inches, 24 inches, 36 inches, even bigger. Big pipes handle huge gas volumes needed for cities and industries.

What steel is used?

The pipes are made from carbon steel or low alloy steel. This steel handles high pressure. It resists cracks well. The steel composition is carefully controlled. This ensures toughness and weldability for safe pipeline construction.

How are these pipes protected?

External coating is vital. It stops rust from soil and moisture. Common coatings include fusion-bonded epoxy (FBE) or three-layer polyethylene (3LPE). Internal coating might be used. This reduces friction and prevents corrosion from the gas stream itself. Cathodic protection adds another layer of defense underground.

Why choose higher grades like X60 or L415?

Stronger steel allows thinner pipe walls for the same pressure rating. Thinner walls mean less steel is needed. This reduces material costs. Lighter pipes are also easier to transport and install. But higher-grade steel costs more per ton. The best grade depends on project specifics like pressure and budget.

(Natural Gas Pipe L245 L360 L415 Line Pipe X42 X52 X60 Large Diameter Steel Tubes for Natural Gas Pipelines)

REQUEST A QUOTE

RELATED PRODUCTS

Medical Copper Pipe For Medical Gas Copper Piping Medical Grade Copper Tube 8mm 10mm 12mm 15mm

6mm 16mm Wall Thickness Octg Grdae K55 N80 L80 Carbon Seamless Steel Pipe

Good Quality ASTM AISI A53 Carbon Steel Pipe Seamless Steel Pipes for Oil Gas

Stainless Steel Low Temperature Bellows DN40 Gas Liquid Pipe Liquid Oxygen Nitrogen LNG Metal Jacketed Hose Cryogenic Bellows

Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes

China Factory s ASTMSch 40 18 DN750 30″ Sch Std CARBON STEEL PIPE

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677