LUOYANG DATANG ENERGY TECH CO.,LTD

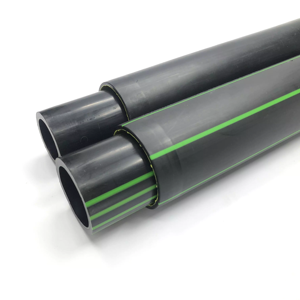

Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply

PRODUCT PARAMETERS

Description

Overview of Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply

Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply)

Specifications of Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply

We supply plastic PE polyethylene HDPE buried gas pipelines for risk-free underground gas shipment. Our pipes deliver natural gas securely under roads, structures, and open ground. They are made from high-density polyethylene product. This material is really strong and lasts a very long time. It resists cracks and breaks very well. The pipes manage pressure accurately. They won’t rust or rot like metal pipelines. This implies less upkeep and longer life underground.

Our gas pipes come in different dimensions. Common diameters are 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 75mm, 90mm, 110mm, 125mm, 140mm, 160mm, 180mm, 200mm, 225mm, 250mm, 280mm, 315mm. Wall surface density adheres to SDR requirements like SDR 11 and SDR 17.6. Standard sizes are 6 meters or 12 meters. The pipelines are generally black with a blue stripe. The red stripe shows it’s for gas usage. Stress scores are PN 6, PN 8, PN 10, PN 12.5, PN 16. This covers different gas network requirements.

Setup makes use of butt blend welding. This method produces very solid, leak-proof joints. The pipes are adaptable. This allows flexing around challenges without additional fittings. They take care of ground motion well. The smooth inner surface area keeps gas circulation effective. It lowers friction loss. This assists preserve stress over range.

Our pipes satisfy stringent worldwide safety standards. They are certified for gas circulation networks. They withstand lots of chemicals found in soil. This protects against damages. The product is non-conductive. This avoids electric dangers. We guarantee high quality and efficiency. Our pipes guarantee secure, dependable gas supply for many years.

(Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply)

Applications of Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply

For trusted underground gas distribution, plastic HDPE pipelines offer a strong service. These pipes are made from challenging polyethylene plastic. They handle high pressure safely. HDPE does not rust like steel pipes. This is crucial for gas lines buried in dirt. Rust creates leakages and costly fixings. HDPE prevents this trouble entirely. It stands up to chemicals in the ground as well. This material remains solid for years underground.

Installing HDPE gas pipeline is effective. The pipes come in long, flexible coils. Employees need fewer links along the course. Less joints imply fewer possible leakage factors. This makes the whole system safer. The pipes flex conveniently around challenges. This saves excavating time and minimizes disturbance. You do not require heavy machinery to bend them. They join making use of heat blend, not mechanical fittings. Warm combination develops a seamless, watertight bond. The joint ends up being as strong as the pipeline itself. This method is really dependable.

HDPE pipelines stand up to cracks and damage well. They handle ground movement better than stiff pipes. Cold and thawing cycles trigger much less tension. The product takes in influences without damaging. This sturdiness implies less issues later on. Maintenance prices are lower over the pipeline’s life time. You stay clear of continuous look for corrosion. The smooth inside surface area maintains gas moving effectively. Less rubbing suggests lower pumping prices. Utilizing HDPE saves money during installment and for several years after. It offers a trustworthy gas supply network.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply

Plastic HDPE Gas Pipe FAQs

Is this plastic pipe safe for gas?

Yes. Our HDPE gas pipes meet strict industry standards. They are certified for underground gas supply. The material resists cracks and leaks. Proper installation ensures long-term safety.

How do you install HDPE gas pipe underground?

Installation uses trenching or directional drilling. Workers fuse pipe sections together using heat. This creates seamless, leak-proof joints. The pipe is then buried at the required depth below ground. Trained crews follow specific procedures.

How long does HDPE gas pipe last?

HDPE gas pipe lasts a very long time underground. It typically performs well for over 50 years. The pipe resists environmental stress and degradation. Proper installation and quality materials are key to reaching this lifespan.

Why choose HDPE over metal pipes for gas?

HDPE offers big advantages. It doesn’t rust or corrode like metal. This is crucial underground. Installation is often faster and cheaper. HDPE is also lighter and more flexible. It handles ground movement better than rigid metal pipes.

Does soil or water damage the pipe?

No. HDPE pipe is highly resistant. Common soil chemicals and moisture don’t harm it. The material won’t rot or break down. It provides a reliable barrier for the gas inside. This makes it perfect for buried applications.

(Plastic PE Plyethylene HDPE Buried Gas Pipe for Gas Supply)

REQUEST A QUOTE

RELATED PRODUCTS

S355 Weld Carbon Steel Pipe

Q195 Q215 Q345 Q275 Carbon Steel Round Square Tube Pipe ASTM GB JIS DIN BS Carbon Steel Pipes

Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build

China Carbon Steel Pipe Seamless Hot Rolled Steel Tube 20# Carbon Steel Pipe

API 5L X42 X52 X56 X60 X70 SSAW Large Diameter 15mm-3000mm Carbon Ms Spiral Welded Steel Pipelines For Water Oil Gas Steel Pipe

API 5L ASTM A106 A53 Grad B Round Black Carbon Seamless Steel Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677