LUOYANG DATANG ENERGY TECH CO.,LTD

Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline

PRODUCT PARAMETERS

Description

Overview of Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline

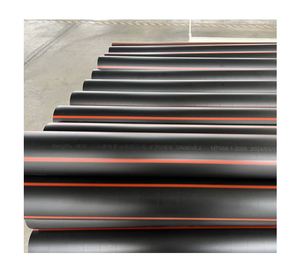

Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline)

Specifications of Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline

These steel pipes meet rigorous standards for oil and gas pipes. They are constructed difficult. ASTM A106, A53, API 5L GR.B, and API 5CT K55 grades are available. These qualities take care of high pressure and harsh conditions. Typical sizes range from 1/2 inch to 24 inches. Wall density adheres to timetables like SCH 40, SCH 80, SCH 120, and SCH 160. Thicker wall surfaces deal with even more stress.

Manufacturing uses smooth or ERW approaches. Seamless pipelines are stronger for crucial high-pressure lines. ERW pipes are cost-efficient for several applications. Material is carbon steel. This steel is strong and weldable. It performs well sought after environments.

The pipelines transport oil, natural gas, water, and vapor. They are also utilized in architectural projects. Surface area surfaces consist of black, galvanized, or covered. Layer safeguards versus rust. Beveled ends are basic for very easy welding connections. Proper welding is crucial for pipeline safety and security.

Extensive screening guarantees high quality. Hydrostatic tests check pressure resistance. Non-destructive tests discover hidden flaws. Chemical analysis verifies product make-up. Mechanical tests verify stamina and toughness. Each pipe set includes mill examination certifications. These papers show compliance with the requirements.

Quality assurance is stringent throughout production. Factories keep ISO qualification. Third-party evaluation prevails. Traceability from raw material to final pipe is ensured. Packaging uses steel strips or wooden pet crates. This protects against damage during delivery. The pipes work in temperatures from -20 ° C to over 400 ° C. Certain temperature level limitations depend on the quality and application.

(Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline)

Applications of Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline

These steel pipelines meet stringent sector standards. They’re built difficult for requiring oil and gas jobs. Believe pipelines moving petroleum and gas cross countries. Think pipes inside refineries processing gas. Assume casing and tubing securing wells deep underground.

ASTM A106 pipes manage high pressure and warm. They’re common in refineries and power plants moving hot fluids. A53 pipelines are general workhorses. They carry water, gas, or oil at reduced pressures. Both see heavy use in surface pipelines.

API 5L GR.B pipelines are pipeline professionals. They create the backbone of cross-country transmission lines. They bring oil and gas safely from fields to handling facilities. Their toughness withstands the continuous pressure inside.

API 5CT K55 pipes are for well building and construction. They function as covering, lining the pierced opening to stop collapse. They keep the wellbore secure and separate various areas underground. Tubing made from this quality brings the oil or gas up to the surface area.

These pipes are necessary. They develop the surprise network supplying energy resources. Their high quality avoids leakages and failures. They endure severe atmospheres, underground stress, and harsh elements. Picking the right quality ensures security and long-term reliability. Pipeline operators and exploration companies depend on this efficiency daily. Appropriate material choice straight affects task success and environmental management.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline

What are these pipes?

These are steel pipes made for oil and gas work. They meet strict industry standards like ASTM A106, A53, API 5L GR.B, and API 5CT K55. Factories build them for pipeline systems carrying oil, gas, or other fluids.

What material are they?

The pipes are carbon steel. This material is strong. It handles high pressure well. It resists wear over time. This makes it reliable for tough pipeline jobs underground or above ground.

Where are they used?

Their main job is in oil and gas pipelines. They transport crude oil, natural gas, and refined products over long distances. You also find them in gathering lines near wells. Sometimes they are used in processing plants too.

What sizes and thicknesses are available?

Factories offer many sizes. Outer diameters range from small (like 1/2 inch) to very large (over 24 inches). Wall thickness varies too. Thicker walls handle higher pressures. Common schedules are SCH 40, 80, 160, and XXS. Specific sizes depend on the pipe standard.

How do the different grades matter?

Each grade (like A106 B, API 5L B, K55) has slight differences. They vary in strength, chemical makeup, and testing rules. A106 and A53 pipes are often for general high-temperature service. API 5L GR.B is specifically for transmission pipelines. API 5CT K55 is mainly for well casing and tubing. Choose the grade matching your project’s pressure needs and fluid type.

(Professional Factory ASTM A106 A53 API 5L GR.B Api 5ct K55 Steel Pipe Tube For Oil And Gas Pipeline)

REQUEST A QUOTE

RELATED PRODUCTS

ASTM A106/A53 Gr. B API 5L Gr. B A179/A192/API 5CT J55/K55/N80 Carbon Seamless Steel Pipe Oil 6m 12m Certified API GS Tisi Emt

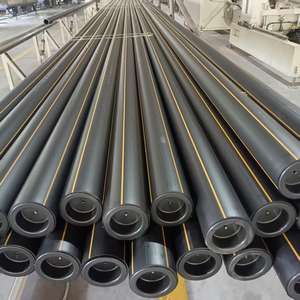

Customizable Large Caliber HDPE Plastic Tube HDPE Gas Pipe

ASTM A53 Gr. B ERW Carbon Steel Pipe Welded Round Pipe for Petroleum and Natural Gas Pipelines and Buildings

Factory Direct Large Diameter SSAW Carbon Welded Steel Pipe With Pvc Coated Iron or 3PE For Oil and Gas Industry

Api 5l X52 SMLS Thick DN150 DN200 Sch 40 CS Seamless Steel Petroleum Pipes

6mm 16mm Wall Thickness Octg Grdae K55 N80 L80 Carbon Seamless Steel Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677