LUOYANG DATANG ENERGY TECH CO.,LTD

Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe

PRODUCT PARAMETERS

Description

Overview of Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe

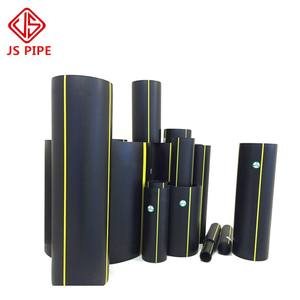

Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe)

Specifications of Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe

This retractable gas hose pipe handles oxygen and acetylene safely for medical and industrial work. Think welding, soldering, cutting, brazing. Its core job is moving these gases reliably from cylinders to torches or equipment. Safety is critical. These hoses resist sparks, flames, and abrasions. They won’t melt or catch fire easily near your work. This prevents accidents.

The hose material is strong rubber or PVC. This inner tube holds the gas without leaking. A tough fabric layer wraps around it. This layer adds strength. An outer cover protects everything from weather, oil, chemicals, and physical damage. The hose stays flexible in cold and hot conditions. You can bend it without kinking. Kinks block gas flow. That’s dangerous.

The retractable feature is key. The hose coils back neatly into its housing when you finish. This keeps your workspace tidy. No more tripping over tangled hoses. It saves space on carts or in workshops. Just pull the hose out to the length you need. It locks in place. Release it, and it retracts smoothly. This makes setup and cleanup much faster.

Important specs matter for safety. Check the maximum working pressure rating. Common ratings are 300 PSI or higher. Never exceed this pressure. Choose the right inner diameter for your gas flow needs. Common sizes are 1/4 inch or 3/8 inch. Lengths vary. Standard retractable hoses offer 10 meters or 15 meters of reach. This gives you good mobility. The hose connects using standard fittings. These are usually BSP or NPT threads. Ensure they match your regulators and torches. A tight seal prevents leaks. Leaks are a serious fire or explosion hazard. Always inspect the hose before use. Look for cracks, cuts, or bulges. Replace damaged hoses immediately. Never repair them yourself. Use only hoses certified for oxygen and acetylene service. Using the wrong hose type is extremely risky.

(Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe)

Applications of Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe

Retractable gas hose pipes deliver gases safely for medical and industrial work. They are vital tools. Medical facilities use these hoses for oxygen and other medical gases. Reliable gas flow is critical for patient care. These hoses ensure consistent delivery. They prevent dangerous interruptions. Cleanliness matters greatly in medical settings. The smooth surface of retractable hoses resists dust and germs. This helps maintain sterile environments.

Industrial applications demand tough hoses. Welding and soldering rely heavily on oxygen and acetylene gases. These gases are highly flammable. Safety is the top concern. Retractable gas hoses are built for this. They use special flame-retardant materials. This greatly reduces fire risks. The hoses resist sparks and heat near the work area. Accidental damage is a constant worry in busy workshops. Retractable hoses minimize this risk. They coil away neatly when not needed. This stops trips and falls. It also protects the hose from cuts and crushing.

Kinks are a big problem with gas hoses. A kinked hose blocks gas flow. Blocked flow disrupts work. It can even create dangerous pressure build-ups. Retractable hoses are designed to resist kinking. This ensures smooth, uninterrupted gas supply. Consistent flow is essential for good welding and soldering results. Workers need to move freely around equipment. The retractable feature gives them extra reach. It pulls the hose back automatically. This keeps work areas tidy and safe. Durability is key for industrial use. These hoses withstand rough handling, oils, and chemicals common in factories. They last longer under tough conditions. Choosing the correct retractable hose is important. Match the hose specifically to the gas type and pressure needed. Oxygen service requires special, oil-free hoses. Using the wrong hose is unsafe. Always follow the manufacturer’s instructions for installation and use. Regular inspection for wear or damage is mandatory. Replace damaged hoses immediately. Safety cannot be compromised. Retractable gas hose pipes offer a smart solution. They improve safety, organization, and efficiency in demanding medical and industrial tasks. They protect people and processes.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe

Retractable Gas Hose Pipe FAQs: Medical, Industrial, Welding, Oxygen, Acetylene

1. Why choose a retractable gas hose pipe?

Retractable hoses prevent tangles and kinks. Tangles and kinks are dangerous. They can cause leaks or block gas flow. A retractable hose coils neatly after use. This keeps your workspace clear. It reduces tripping hazards. It also protects the hose from damage. Damage leads to leaks.

2. What material is safe for oxygen and acetylene?

Only use hoses specifically designed for these gases. Standard rubber hoses are unsafe. Acetylene requires special rubber. This rubber resists the solvent effect of acetylene. Oxygen needs oil-free materials. Oil contact with oxygen can cause fire or explosion. Our hoses use the correct rubber compounds. They are marked for oxygen or acetylene service. Never mix them up.

3. How much pressure can these hoses handle?

Check the working pressure rating. This rating is printed on the hose. It must match or exceed your equipment’s needs. Industrial welding hoses often handle higher pressures. Medical oxygen houses handle lower pressures usually. Using a hose below its rated pressure is safe. Exceeding the pressure rating is dangerous. The hose could burst. Always know your system’s pressure.

4. Are certifications important?

Yes, absolutely. Certifications prove the hose meets safety standards. Medical oxygen hoses need strict approvals. Look for certifications like ISO 13485. Industrial welding hoses need standards like EN 559 or equivalent. These standards cover material safety and pressure performance. Never use an uncertified hose for medical or industrial gas. Safety depends on it.

5. Are these hoses fire resistant?

Welding and soldering create sparks and heat. Normal rubber burns easily. Our safety hoses are flame retardant. They resist ignition from sparks or brief flame contact. This is crucial near open flames or hot work. Check the hose specifications. Look for flame resistance ratings. This feature adds a vital safety layer.

(Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality API 5L ASTM Seamless Oil Pipe Gas Pipe

Plastic High Pressureg Gas Hose Pipe Pvc lpg Pipe Pneumatic Hose

ASTM A106 A53 GrB API 5L Gr.B Seamless Carbon Steel Pipe Casing Pipe Good Per Ton

4 Size Fuel Line Hose Petrol Tubing Common ForWeedeater Trimmer Chainsaw Blower Gasoline Pipe Petrol Pipe

Fire Fighting Material Red Painted Sch10 Weld Carbon Steel Fire Sprinkler Pipe/tube

ASTM A53 Gr. B ERW Schedule 10 Black Carbon Steel Pipe Used for Oil and Gas Pipeline in Hebei

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677