LUOYANG DATANG ENERGY TECH CO.,LTD

Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe

PRODUCT PARAMETERS

Description

Overview of Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe

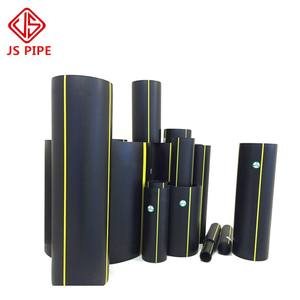

Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe)

Specifications of Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe

Seamless steel pipes are important for oil and gas procedures. These pipelines are made from carbon steel. The smooth production procedure is crucial. It involves creating a strong steel billet into a pipe with no joints. This develops a smooth, continual interior birthed. The smooth bore lessens rubbing during drilling. It helps liquids and gases circulation successfully downhole.

These pipelines offer critical duties. They work as casing to line pierced wells. They prevent the wellbore from falling down. They also separate different underground developments. The pipes act as drill pipe as well. They transmit drilling torque and weight to the drill bit deep underground.

Criterion sizes prevail. External diameters frequently range from 4 1/2 inches to 20 inches. Wall density varies substantially. Thickness depends on the required pressure ranking and depth. Usual qualities include API 5CT J55, K55, N80, L80, C90, T95, P110. Various qualities use different strength degrees and rust resistance. Higher grades handle better pressures and harsher problems.

Carbon steel gives great strength and sturdiness. It withstands the requiring downhole atmosphere. This environment entails high pressure, mechanical tension, and destructive aspects. The seamless construction guarantees uniform strength. There are no bonded seams to develop powerlessness. This is important for safety and security and reliability popular oil and gas applications. These pipes are vital tools for expedition and production companies worldwide. They develop the backbone of contemporary drilling procedures.

(Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe)

Applications of Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe

Smooth steel pipelines are vital for the oil and gas industry. They’re incredibly strong and reputable. You discover them deep underground and offshore. They take care of extreme pressure and heat. They stand up to breaking and leaks. This makes them excellent for requiring settings.

Oil and gas wells require strong walls. Smooth steel casing pipelines supply that strength. They line the wellbore. This protects against collapse. It additionally shields groundwater from contamination. Casing pipes maintain whatever steady and risk-free underground. Various sizes and thicknesses suit various well midsts and pressures.

Drilling calls for difficult pipelines as well. Seamless steel drill pipes deliver power deep underground. They attach the surface area rig to the drill bit. They rotate the little bit. They bring drilling liquid down. This fluid cools down the little bit and brings rock cuttings up. Smooth drill pipelines deal with intense twisting pressures and heavy lots. They last longer under hard exploration conditions.

Moving oil and gas requires safe pipelines. Smooth steel tubes moves these sources safely. It lugs oil, gas, and various other fluids within the well. It also moves them through gathering systems. Smooth tubes makes sure smooth flow. It decreases clogs. Its consistent shape reduces friction. This conserves energy.

These pipelines likewise benefit surface devices. They attach shutoffs, pumps, and containers. Smooth pipelines manage high pressure in handling plants. They stand up to use from sand and various other bits. Their smooth inside stops buildup. This implies less upkeep downtime.

Rust is a big trouble. Smooth carbon steel pipelines stand up to rust well. They last longer in wet or salted problems. They take care of extreme chemicals utilized in drilling and manufacturing. This integrity is important for remote operations. Changing pipelines is pricey and difficult.

The production procedure issues. Smooth pipes have no welded seams. This gets rid of weak points. They are developed from a solid steel billet. This develops a consistent structure. The pipeline is more powerful all over. It carries out much better under stress. It manages pressure rises securely.

Quality control is stringent. Seamless pipelines for oil and gas meet high requirements. They comply with API specifications specifically. This guarantees safety and security and efficiency. Business trust these pipes for critical work. They understand smooth pipes will not fail all of a sudden. Using them stops accidents and secures the environment. These pipes are additionally common in nuclear power plant and chemical factories. They carry steam, water, and other fluids accurately. Their toughness sustains huge structures and machinery.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe

Here are 5 FAQs about Seamless Steel/Oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe:

What sizes do you offer?

We make many sizes. Common diameters range from 2 3/8 inches to 20 inches. Wall thickness varies too. We match your specific drilling depth and pressure needs. Tell us your project requirements.

What standards do these pipes meet?

Our pipes meet strict industry rules. They follow API 5CT and API 5DP standards. These cover material quality and testing. This ensures safety and performance in tough oil and gas conditions. We also meet ASTM and ASME standards.

Why choose seamless pipe over welded pipe?

Seamless pipes have no welded seam. This makes them stronger. They handle high pressure better. They resist collapsing or bursting underground. Seamless pipes are more reliable for deep wells and harsh environments. This reduces failure risk.

Where are these pipes used?

These pipes are essential for oil and gas wells. They form the casing lining the drilled hole. They protect the wellbore. They also work as drill pipe. Drill pipe transmits power to the drill bit deep underground. They are vital for exploration and production.

How do you ensure pipe quality?

Quality is critical. We test every pipe carefully. We use ultrasonic testing to find hidden flaws. We perform hydrostatic tests checking for leaks under pressure. We check the pipe dimensions precisely. We inspect the steel quality. Our strict process guarantees dependable pipes.

(Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

ASTM A795 Fire Sprinkler Steel Pipe Seamless Steel Pipes Oil and Gas Carbon Pipelines

ASTM A106/A53 20# Round Q235/Standard Factory High-Quality Hot-Rolled Seamless Ms Carbon Steel Pipes

4 Size Fuel Line Hose Petrol Tubing Common ForWeedeater Trimmer Chainsaw Blower Gasoline Pipe Petrol Pipe

Good s in Europe Market Api 5l X70 X52 Lsaw Pipe Din 2448 St37 Carbon Steel Pipe Tube Petroleum Gas Oil Seamless Tube

High Quality Carbon Steel Pipe Q235 Q345, ASTM A53 API 5L, OD 1/2″-48″, Thickness SCH10-SCH160, Exported To USA, UK, Australia

Galvanized Steel Pipe/hose/tube For Water Gas Galvanized Steel Tube 45 X 45 X 2mm 4m Long

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677