LUOYANG DATANG ENERGY TECH CO.,LTD

Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline

PRODUCT PARAMETERS

Description

Overview of Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline

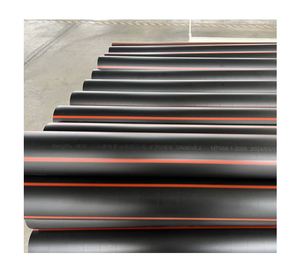

Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline)

Specifications of Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline

This pipe is carbon steel smooth pipeline. It’s made for oil and gas pipelines. The pipe is created with no welding seam. This makes it really solid all over. It handles high pressure well. This stamina is vital for pipeline security.

Carbon steel provides the pipe great toughness. It resists damaging under stress and anxiety. The pipeline additionally handles high temperatures dependably. This is essential for moving warm oil or gas. Its smooth nature indicates no weak points exist along its size. Welded pipelines can have powerlessness. This pipeline avoids that problem completely.

The pipeline comes in several dimensions. Wall density can differ as well. This adaptability meets different project requirements. Common sizes are readily available. Personalized dimensions are typically feasible. The pipeline meets rigorous sector requirements. These criteria cover material quality and measurements. Requirements like API 5L and ASTM A106 are regular. This guarantees constant performance.

The smooth inside surface is a key benefit. It allows oil and gas to stream easily. Much less friction means far better circulation performance. It likewise lowers buildup inside the pipe. This aids maintain the pipe tidy. Upkeep requirements are often reduced. The pipeline lasts much longer with appropriate treatment. It endures extreme pipeline conditions efficiently. Rust resistance is adequate for many atmospheres. Special finishes can be added for extra security. This pipeline is a trustworthy selection for vital power transportation. Its proven performance sustains risk-free pipe operations.

(Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline)

Applications of Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline

Smooth steel pipelines are important for oil and gas pipes. They relocate oil and gas securely over long distances. These pipelines encounter high stress and harsh conditions. Carbon steel smooth pipes manage this well. They are solid and reputable.

The pipe has actually no bonded seam along its size. This is crucial. Welds are powerlessness. High pressure can make welds fall short. Seamless pipelines prevent this risk. They are more secure for high-pressure oil and gas lines.

Carbon steel is the primary product. It provides good toughness and sturdiness. Various grades are available. Typical grades include API 5L Quality B, X42, X52, X60, X65, X70, X80. Higher grades imply higher stamina. This lets pipelines handle even more stress. It also allows thinner pipe wall surfaces. Thinner wall surfaces save material and lower weight. This lowers expenses.

The smooth procedure makes the pipeline wall attire. The wall density is consistent all around. This is very important. It stops vulnerable points. It makes sure the pipeline does equally under pressure. This uniformity is more challenging to accomplish with welded pipeline.

These pipes function below ground and above ground. They bring crude oil from wells. They deliver natural gas to processing plants. They relocate refined items to storage. They are made use of in event lines and transmission lines. Collecting lines collect from lots of wells. Transmission lines lug the oil or gas fars away. Seamless pipelines manage the pressure in both.

Corrosion is a big issue for pipes. Smooth carbon steel pipelines withstand rust well. They can also have special coverings. Coatings offer added security. This makes the pipes last longer. Longer life indicates lower substitute prices. It likewise implies less downtime.

The smooth inside surface area of smooth pipe aids flow. Oil and gas relocate extra easily. There is less rubbing. This minimizes the power needed for pumping. It improves performance. Much less power use conserves money and is better for the setting.

Pipelines cross lots of settings. They undergo deserts, hills, and undersea. Smooth pipes withstand various temperatures and stress and anxieties. They are tough. They are reliable. They are the leading selection for crucial oil and gas framework. Their toughness and safety and security document show their worth.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline

Seamless steel pipe means one solid piece of steel formed into a tube. Carbon steel seamless pipe is vital for oil and gas pipelines. It moves oil and gas safely over long distances. Here are five common questions about this pipe.

What is seamless steel pipe? It’s a pipe made without welding a seam. Manufacturers start with a solid steel cylinder. They heat it. They pierce it through the center. They stretch and roll it into a hollow tube. This method creates a pipe with consistent strength all around.

Why use seamless pipe for oil and gas? Seamless pipe is very strong. It handles high pressure inside pipelines. It withstands the stress of burying the pipe deep underground. Its seamless nature means no weak points along its length. This prevents leaks. Leaks are dangerous and expensive.

How is carbon steel seamless pipe made? The main process is hot rolling. A heated steel billet gets pierced by a mandrel. The pipe is then elongated using rolling mills. Sometimes it’s cold drawn for precise sizes and smoother finishes. Heat treatment follows. This ensures the steel has the right properties for toughness.

What sizes and pressure ratings exist? These pipes come in many sizes. Common diameters range from half an inch to over 24 inches. Wall thickness varies significantly. Thicker walls handle higher pressure. The pipe must meet specific standards like API 5L. This standard defines the grades and pressure capabilities.

How is quality ensured? Manufacturers perform strict tests. They check the pipe dimensions carefully. They test the material strength by pulling samples apart. They inspect the pipe inside and out for flaws. They often perform hydrostatic tests. Water pressure inside the pipe proves it holds pressure safely. Non-destructive tests like ultrasound find hidden problems.

(Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline)

REQUEST A QUOTE

RELATED PRODUCTS

8Mm Gas Pipe Hot ing Eco-Friendly Conveying Water Oil Gas Pvc Pipe Lgp Gas Hose

High Quality New Gas Pipe Gas Intake Pipe K4DQ5-1113960KS1 for Truck

SSAW Spiral Steel Pipe Piles Large Diameter Carbon 16inch Sch 40 Ms Spiral Welded Steel Pipe for Water Oil and Gas

Competitive s Astm A106 Grade B Hot Rolled Steel Tube Carbon Seamless Steel Pipe Welded Steel Pipes

Fluid Pipeline Carbon Steel Pipe API 5L GrB X52 X60 Seamless Tubes

Russian GOST 8732-78 Seamless Steel SMLS Gas Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677