LUOYANG DATANG ENERGY TECH CO.,LTD

Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing

PRODUCT PARAMETERS

Description

Overview of Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing

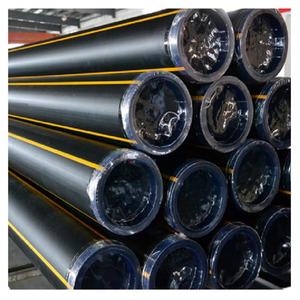

Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing )

Specifications of Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing

Smooth steel pipeline is vital for the oil and gas sector. It safely moves oil and gas under high pressure. This pipe deals with severe conditions deep underground or underwater. API 5L and ASTM standards specify the quality. These pipes are made from carbon steel.

Suppliers utilize warm rolling or cool illustration. Hot rolling forms heated steel billets. This procedure develops strong, sturdy pipelines. Cold attracting pulls cooled down steel through dies. This approach attains tighter resistances and a smoother coating. Both techniques guarantee no welding seams exist. Smooth building is crucial. It stops leakages under pressure.

The pipe wall thickness is consistent. This is critical for regular toughness. It resists breaking and breaking down. API 5L qualities like X42, X52, X60, X65, X70, and X80 are common. Greater grades manage greater stress. The pipe goes through extensive screening. Hydrostatic testing look for leakages under high water stress. Non-destructive tests find concealed imperfections. Chemical evaluation verifies the steel structure. Mechanical examinations action strength and toughness.

These pipes hold up against corrosion. They withstand sour gas including hydrogen sulfide. They handle heats. Usual sizes range from 1/8 inch to 26 inches OD. Wall surface thickness differs based upon pressure needs. Smooth pipe is reliable for essential applications. Pipes, well cases, and risers use it. Safety and security relies on its integrity.

(Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing )

Applications of Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing

Smooth steel pipes are essential for the oil and gas industry. They relocate oil and gas securely over cross countries. These pipelines handle high stress underground and over ground. API 5L and ASTM requirements ensure their quality and efficiency. This is essential for requiring oil and gas procedures.

These pipes develop the foundation of major pipelines. They deliver petroleum from fields to refineries. They bring gas from manufacturing sites to cities and nuclear power plant. Their smooth building and construction indicates no weak seams. This prevents leaks under high stress. It guarantees trustworthy, lasting service in extreme atmospheres.

Smooth steel pipes are additionally necessary inside oil and gas wells. They act as covering. Casing lines the wellbore walls. It stops the opening from collapsing. It separates different underground layers. This safeguards freshwater sources. It regulates stress throughout drilling and production. API 5L pipes are specifically made for this tough job.

Smaller size smooth pipelines function as tubes inside the covering. Tubes brings the oil or gas up to the surface area. It stands up to inner pressure and destructive liquids. Hot-rolled and cold-drawn seamless tubes provides the needed strength and precision. Cold-drawing improves surface area finish and dimensional precision. This is essential for reliable well operation.

Smooth pipelines are used for drill pipes also. Pierce pipes connect the surface area rig to the drill bit deep underground. They transmit torque and exploration liquid. They sustain enormous anxiety, bending, and resonance. Smooth building provides the necessary strength and reliability. API criteria ensure they meet these severe needs.

The toughness of smooth carbon steel is essential. It takes care of high pressure inside pipes and wells. It withstands the physical stress and anxieties of exploration and production. It copes with temperature level variants. Seamless pipes provide remarkable dependability compared to welded alternatives. They are the trusted choice for safety and security and efficiency.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing

Here are 5 FAQs about Seamless Steel Pipe for Oil and Gas, API 5L ASTM Carbon, Hot-Rolled Cold Drawn Tubing:

What is this pipe?

This pipe is seamless steel tubing. It carries oil and gas. It is made from carbon steel. It meets strict API 5L and ASTM standards. The pipe has no welded seam. This makes it very strong. It handles high pressure well. It resists leaks. It is essential for safe oil and gas transport.

What steel grades are used?

Common grades are API 5L X42, X52, X60, X65, X70, X80. The grade shows the minimum yield strength. Higher numbers mean stronger steel. X52 pipe is stronger than X42 pipe. The right grade depends on the project pressure needs. ASTM A106 and A53 grades are also used for some applications.

Hot-rolled versus cold-drawn? What’s the difference?

Hot-rolled pipe is shaped at high temperatures. It is generally larger in diameter. It has thicker walls. Cold-drawn pipe is formed at room temperature. It is pulled through a die. This process makes the pipe very precise. Cold-drawn pipe has a smoother surface. It has tighter dimensional tolerances. It is often stronger than hot-rolled pipe of the same grade. Hot-rolled is common for large pipelines. Cold-drawn suits high-precision needs like instrumentation.

What standards control this pipe?

API 5L is the main standard. It covers seamless and welded line pipe. It defines chemical composition. It defines mechanical properties. It defines testing methods. ISO 3183 is an equivalent international standard. ASTM standards like A106 and A53 are also used. These cover seamless carbon steel pipe for high-temperature service. Compliance ensures safety and performance.

Where is this pipe used in oil and gas?

It is used everywhere. It builds long-distance transmission pipelines. It is used for gathering lines in fields. It is used for drilling applications. It is used inside refineries. It connects wellheads. It is used for high-pressure flow lines. It is used for injection lines. Its strength and leak resistance are critical. It transports crude oil. It transports natural gas. It transports other hydrocarbons.

(Seamless Steel Pipe For Oil And Gas Industry API 5L ASTM Carbon Hot-Rolled Cold Drawn Tubing )

REQUEST A QUOTE

RELATED PRODUCTS

UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes

DN200-DN3800 Thick Steel Tube SSAW 609 mm Carbon Steel Pipe Helical Seam Spiral Welded Steel Pipe Used for Oil and Gas Pipeline

Shine Universe Fiberglass Tube Fiber Glass Pipe Fiberglass Tube/Pipe GFRP Pipe

2024 China New Carbon Steel Seamless Pipe 6 Inch Customized Size Fluid Gas /oil Seamless Water Pipe

Precision Hot Rolled Customized Black Seamless Carbon Steel Pipe A53 A106 ST37 ST45-8 ST Spot s

Industrial Grade Hot Rolled Carbon Steel Round Tube API 5CT J55 Black Painted Carbon Pipe for Oil and Gas Pipeline

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677