LUOYANG DATANG ENERGY TECH CO.,LTD

Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose

PRODUCT PARAMETERS

Description

Overview of Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose

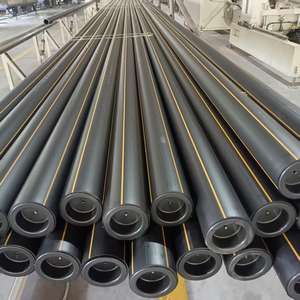

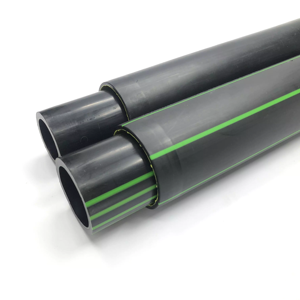

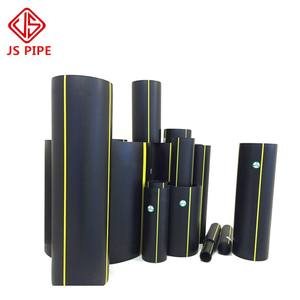

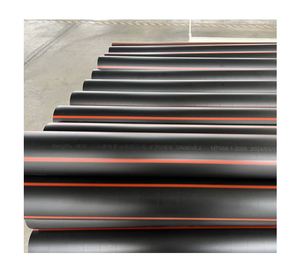

Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose)

Specifications of Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose

Here are the requirements for our semi-trailer spiral pipe link brake tube. This pipe links essential air brake system parts. It carries pressed air dependably. Safety and security and performance are important.

We build this tube challenging. A solid spiral wire support rests inside. This wire makes the tube extremely strong. It protects against bursting under high stress. Abrupt stress rises won’t blow it apart. This is the explosion-proof design. It maintains the air brake system secure.

The tube takes care of extreme temperatures well. It executes in deep chilly down to -40 ° C. Winter conditions won’t make it fragile. It additionally functions penalty in high warm up to 120 ° C. Engine warm won’t damage it. This chilly and heat resistance guarantees year-round reliability.

The inner tube makes use of special synthetic rubber. This rubber stands up to oil and ozone damage. It will not break or degrade rapidly. The external cover is difficult synthetic rubber as well. It shields against abrasion and climate. Sunlight, rainfall, and roadway chemicals trigger very little injury.

The tube takes care of high working pressure. It meets rigorous sector pressure rankings. It maintains its shape and toughness under load. Versatile building and construction allows simple transmitting around trailer components. It flexes without kinking. This prevents air flow restriction.

End installations are long lasting steel. They attach securely to gas pipelines or air system parts. These links are leak-proof. The spiral wire reinforcement expands right to the installations. This makes sure optimal stamina at connection points. This hose pipe is developed for demanding semi-trailer stopping systems. It delivers dependable air flow.

(Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose)

Applications of Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose

These tubes are difficult. They handle requiring work. Semi-trailers use them a great deal. The spiral pipe connection provides stamina. It stops twists and crushing. Hefty lots and constant motion take place. These hose pipes hold up. Moving gas requires safety and security. These hose pipes are explosion-proof. They withstand stimulates and static. Leaks are dangerous. These hose pipes prevent leakages. They transport gas securely. Factories and chemical plants utilize them. They need reputable transfer.

Severe temperature levels prevail. Brake systems encounter this. Winter makes points brittle. High warm softens products. These pipes resist both. They operate in freezing wintertimes. They work near hot engines. Efficiency remains regular. Brake fluid pressure is important. These hose pipes deal with the pressure. Security depends on it. The spiral reinforcement helps here. It includes burst strength. Unexpected stress spikes take place. The tube will not fall short.

Sturdiness issues. These tubes resist abrasion. Road particles hits them. Oils and chemicals call them. They don’t degrade quickly. Lengthy life span saves money. Maintenance costs go down. Integrity rises. Selecting the ideal hose pipe is necessary. Match it to the work. Check the pressure score. Verify the temperature variety. Validate explosion-proof qualification. Proper installation is vital. Comply with the manufacturer’s guidelines. Drip tests are vital. Safety and security is the priority. These hoses deliver performance. They maintain operations running.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose

Here are 5 FAQs about Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose:

What is this brake hose for?

This brake hose is specifically designed for semi-trailers. It connects the air brake system parts. It carries compressed air safely. It makes the brakes work correctly.

Why does it have a spiral pipe connection?

The spiral pipe connection is crucial. It provides extra strength. It protects the inner hose layer. This prevents kinking or collapsing under high pressure. The spiral design ensures air flows freely. It gives reliable braking power.

What temperatures can it handle?

This hose withstands extreme cold and heat. It works in very low winter temperatures. It also works in high summer heat near engines. The special materials won’t crack in the cold. They won’t soften or degrade in the heat. Performance stays consistent.

Is it really explosion-proof?

Yes, it’s built to resist explosion. The reinforced layers and spiral guard contain high pressure. They prevent sudden bursts. This is vital for safety. Air brake systems use high pressure. A burst hose causes brake failure. This design prevents that.

How easy is it to install?

Installation uses standard methods. Match the fittings to your trailer’s system. Ensure the hose length is correct. Avoid sharp bends during routing. Secure it properly. Always follow the manufacturer’s instructions. Correct installation prevents leaks. It ensures safe operation.

(Semi-trailer Spiral Pipe Connection Gas Pipe Explosion-proof Pipe Cold and High Temperature Resistance Brake Hose)

REQUEST A QUOTE

RELATED PRODUCTS

Plastic High Pressureg Gas Hose Pipe Pvc lpg Pipe Pneumatic Hose

All Specifications Huge Stock Underground Insulation Leakproof PE Yellow Gas Pipe for Gas

High Quality Carbon Steel Pipe Q235 Q345, ASTM A53 API 5L, OD 1/2″-48″, Thickness SCH10-SCH160, Exported To USA, UK, Australia

High Pressure Resistant Lpg Gas Hose Pipe Natural Fuel Line Flexible Air Hose

Seamless Steel Pipe Carbon Steel Seamless Pipe for Oil Gas Pipeline

Fire Fighting Material Red Painted Sch10 Weld Carbon Steel Fire Sprinkler Pipe/tube

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677