LUOYANG DATANG ENERGY TECH CO.,LTD

Spare Parts Aluminium Super Air Pipe for Gas Compressors

PRODUCT PARAMETERS

Description

Overview of Spare Parts Aluminium Super Air Pipe for Gas Compressors

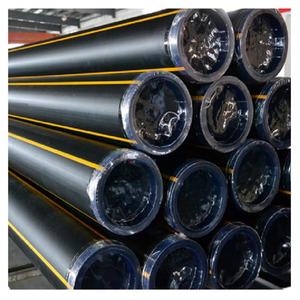

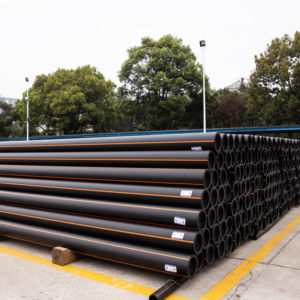

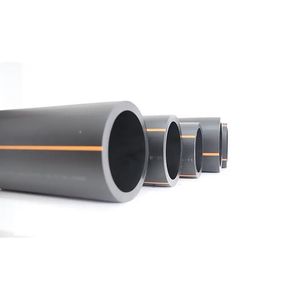

Spare Parts Aluminium Super Air Pipe for Gas Compressors is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Spare Parts Aluminium Super Air Pipe for Gas Compressors

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Spare Parts Aluminium Super Air Pipe for Gas Compressors)

Specifications of Spare Parts Aluminium Super Air Pipe for Gas Compressors

These aluminium extremely air pipes are built for gas compressor systems. They relocate compressed air accurately. Forget plastic pipes that crack under pressure. Aluminium takes care of the tough job easily. It is strong and lasts a long period of time. This pipe resists corrosion and corrosion. Dampness in compressor air won’t harm it. You obtain regular air flow shipment.

The pipe utilizes thick aluminium alloy walls. This quits leakages and endures high pressure. It manages the vibrations compressors make. The pipe will not split or break like less expensive materials. An anodized finishing provides extra protection. This coating fights scratches and chemical damages. The pipeline looks great and remains strong.

Links are safe and secure and simple. Flanged ends or threaded installations are conventional choices. They match common compressor ports. Tight seals protect against air leaks. You shed less pressed air. Your system performance boosts. Installment is basic. Upkeep gets much easier as well. No complex devices are needed.

Warm is no problem for this pipe. Aluminium spreads warmth well. Hot compressor air flows securely. Fire risk is reduced. The product doesn’t support burning. Safety around compressors is important. This pipe aids satisfy security requirements.

Efficiency stays steady. Smooth internal walls lower friction. Air relocates openly without pressure drops. Your compressor does not work more challenging than needed. Energy costs stay reduced. The pipe stays dependable year after year. Downtime for substitutes declines. Production maintains running smoothly.

Select the right size for your compressor. Match the pipe’s stress rating to your system. Correct sizing makes certain peak performance. Buying the right extra component is crucial. Maintain your pressed air system efficient.

(Spare Parts Aluminium Super Air Pipe for Gas Compressors)

Applications of Spare Parts Aluminium Super Air Pipe for Gas Compressors

Gas compressors require tough pipes. Extra components aluminium extremely air pipelines manage this job well. These pipelines relocate warm compressed air securely. They function best where warmth and pressure are high. Assume compressor discharge lines. Also intercooler connections. Aftercooler inlets also.

Aluminium makes sense below. It manages high warmth well. Warm actions away quicker. This stops air from obtaining also warm later on. Much less warmth means better effectiveness. It likewise shields downstream components. Cooler air is more secure air.

Rust is a huge problem with steel pipes. Compressed air often has dampness. Wetness plus steel equates to rust. Rust flakes spoil valves and devices. Aluminium doesn’t corrosion. The within stays smooth. Tidy air keeps streaming. Your tools last longer.

These pipelines are solid. They manage high pressure conveniently. They also take care of resonance. Compressors shake a whole lot. Aluminium flexes a little without breaking. This stops fractures and leaks. Steel pipelines break even more quickly in time.

Setup is simpler. Aluminium pipelines are much lighter. Employees relocate them quickly. Fitting them takes less effort. This conserves time throughout repairs or upkeep. Everybody likes a lighter part to raise.

Leakages lose energy and money. Aluminium pipes seal firmly. Great connections are simple. Flanges or installations work accurately. You obtain the complete pressure you need. No air leaks out.

Condensation can freeze in cool locations. Frozen blocks quit air flow. Aluminium moves warmth quick. This assists stop condensation cold inside the pipeline. Air keeps relocating smoothly.

These pipes last a long time. They withstand deterioration and wear. You won’t change them frequently. This conserves downtime and cost. Tough materials suggest less difficulty.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Spare Parts Aluminium Super Air Pipe for Gas Compressors

What are Spare Parts Aluminium Super Air Pipes?

These are replacement tubes. They connect parts inside gas compressors. They carry compressed air safely. The pipes are made from strong aluminium. They are designed for high-pressure systems. They replace old or damaged pipes easily.

Why use aluminium pipes?

Aluminium pipes are very light. This reduces stress on the compressor parts. They are also very strong. They handle high pressure well. Aluminium doesn’t rust easily. This makes the pipes last longer. They are a reliable choice for tough conditions.

What pressure can these pipes handle?

These pipes handle very high pressure. They are built for industrial gas compressors. The exact pressure rating depends on the pipe size and wall thickness. Always check the specs for your specific model. Using the wrong pipe is dangerous. It can cause leaks or bursts.

Do these pipes resist corrosion?

Yes, aluminium naturally fights corrosion. It forms a protective layer on its surface. This layer blocks rust. This is good for damp or humid environments. It keeps the air clean inside the pipe. Corrosion weakens pipes over time. Aluminium pipes avoid this problem.

Are these pipes hard to install?

Installation is usually straightforward. You need basic tools. First, shut down the compressor safely. Release all pressure from the system. Remove the old, damaged pipe carefully. Fit the new aluminium pipe securely. Make sure all connections are tight. Check for leaks before restarting the compressor. Follow the manufacturer’s guide exactly.

(Spare Parts Aluminium Super Air Pipe for Gas Compressors)

REQUEST A QUOTE

RELATED PRODUCTS

ASTM A106 A53 Hot Seamless Welded Large Diameter 20inch 25inch 30 Inch Carbon Steel Pipe

Factory Specialized in the manufacture of pressure-resistant pvc pneumatic pipe pvc high-pressure gas pipe 8-25mm pvc gas pipe

Hot Galvanized EMT Welded HDG ERW Carbon Steel Pipe 6m 12m Lengths For Container Plate Structure Application JIS Certified

ASTM A53 Welded Or Seamless Carbon Steel Tube Of 50mm Galvanized Steel Pipe In Turkey Galvanised Pipe

Universal Car Fuel Hose Oil Gas Cooler Line Pipe Tube Pipe

High Precision Seamless Pipe Diameter 219mm To 426mm For Oil And Gas Pipeline Transportation

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677