LUOYANG DATANG ENERGY TECH CO.,LTD

Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe

PRODUCT PARAMETERS

Description

Overview of Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe

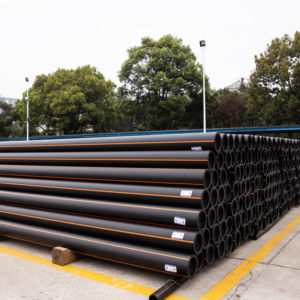

Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe)

Specifications of Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe

Steel pipes are important for many jobs. We make several types. Carbon steel pipelines are solid. They handle hefty tons well. Construction sites utilize these pipelines usually. Galvanized steel pipelines resist rust. They have a zinc coating. This covering secures the pipe. GI pipes are one more name for galvanized iron pipelines. They benefit water lines and outdoor frameworks. ERW pipelines are made by electric resistance welding. This approach signs up with steel strips utilizing electrical present. It produces a strong, consistent seam.

Hot-dip galvanized pipelines get additional security. The pipeline gets dipped in molten zinc. This gives a thick, challenging layer. Black welded pipelines have no coating. They have a dark surface area from the production warmth. Individuals utilize them where look isn’t essential. They commonly get repainted or coated later.

API bonded pipelines fulfill rigorous criteria. The American Petroleum Institute establishes these rules. Oil and gas jobs need API pipelines. They take care of high stress securely. These pipelines are important for pipes and exploration. Oil iron pipe describes pipes created the oil sector. They are built difficult for demanding problems.

Typical materials include ASTM A53 Grade B. This carbon steel is reputable. Sizes vary extensively. External sizes range from 1/2 inch to over 24 inches. Wall surface density depends upon the pipe’s usage. Thicker wall surfaces handle more pressure. Common routines are SCH 40 and SCH 80. Sizes are typically around 6 meters or 12 meters. Pipes can be reduced to specific sizes.

(Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe)

Applications of Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe

Steel pipelines are necessary in many markets. They are solid and long lasting. People utilize them anywhere. Oil and gas pipelines require challenging pipelines. API welded pipes fulfill rigorous criteria for this. They carry oil and gas safely over cross countries. ERW pipelines are common. ERW implies electrical resistance welded. This approach joins steel edges with electrical existing. It produces strong, trustworthy pipes. These pipes function well for water lines too.

Contractors rely heavily on steel pipelines. Building and construction websites use them for structural assistance. They create developing structures and scaffolding. Steel pipes supply solid assistance light beams. They likewise function as columns and trusses. Mechanical systems require them also. Home heating, ventilation, and a/c systems make use of steel tubes. It carries air and water effectively.

Factories depend on steel pipelines. Industrial refines action fluids and gases with them. Water treatment plants need trustworthy piping. Chemical plants call for pipes that withstand corrosion. Galvanized steel pipes (GI pipelines) are essential below. Galvanizing layers steel with zinc. This zinc layer protects the pipe. It lasts a lot longer against rust. GI pipes are terrific for water lines and outdoor fencing.

Hot dip galvanizing offers a thick, protective zinc finishing. Black steel pipelines are another choice. They have a dark oxide scale coating. People frequently utilize them for gas lines below ground or within buildings. They are likewise utilized where appearances aren’t vital. Welded pipelines are made by signing up with steel sides together. This procedure creates a seam. Modern welding makes this joint extremely strong. Welded pipelines handle high pressure well. They suit many requiring tasks.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe

People often ask about steel pipes. They want to know the differences. Carbon steel pipes are common. They are strong. They handle high pressure well. But carbon steel can rust. Rust happens when pipes get wet. Galvanized pipes fight rust better. The galvanizing process adds a zinc layer. This layer protects the steel. Hot-dip galvanizing gives the best protection. The pipe gets dipped in molten zinc. The coating is thick. It lasts a long time. Black pipes have a dark scale coating. This coating offers minimal rust protection. It is mostly for looks. These pipes are cheaper. They are used indoors mostly.

ERW means Electric Resistance Welded. This is how the pipe is made. Steel gets rolled into a tube shape. Then the seam gets welded using electric current. ERW pipes are strong and reliable. They are cost-effective. They are used in many construction jobs. They carry water, gas, and oil.

API standards are important for oil pipes. The American Petroleum Institute makes these rules. API pipes follow strict quality rules. They are made for tough oil and gas work. They handle high pressure safely. They resist corrosion better. Using non-API pipes in oilfields is risky. It might not be safe. It might break.

People ask which pipe lasts longest outdoors. Hot-dip galvanized pipes win here. The thick zinc shield fights weather and moisture. It prevents rust for many years. Basic black pipes rust quickly outside. They are not for outdoor use long-term. Carbon steel pipes need paint or other protection outside.

People also ask about pipe strength. Strength depends on the steel grade and wall thickness. Both carbon steel and galvanized pipes can be strong. The galvanizing process doesn’t make the steel weaker. The pipe carries the load. The zinc is just a shield. ERW pipes are strong enough for most building needs. API pipes are made for much higher pressures. They are for demanding oil and gas pipelines.

(Steel Manufactur Weld Tube Construction Carbon Galvanized Gi Erw Hot Dip Black Welding Api Welded Pipes Oil Iron Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

Retractable Gas Hose Pipe for Medical & Industrial Use Welding & Soldering Oxygen & Acetylene Safety Hose Pipe

Factory Supply ASTM A500 Q235 Q345 ST37 C45 A106 Gr.B A53 20# 45# 1″ 2″ 3″ 4″ 5″ 6″ Sch 40 Carbon Steel Pipe Tube For Building

Galvanized Steel Pipe/hose/tube For Water Gas Galvanized Steel Tube 45 X 45 X 2mm 4m Long

ASTM A106/A53 20# Round Q235/Standard Factory High-Quality Hot-Rolled Seamless Ms Carbon Steel Pipes

Factory Supply API 5L Large Diameter Concrete Spiral Welded Steel Pipes For Oil And Gas

Astm API 5l Gr B A134 A106 A53 SCH 40 Black MS Iron Pipe Hot Rolled Seamless And Welded Carbon Steel Tube

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677