LUOYANG DATANG ENERGY TECH CO.,LTD

UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes

PRODUCT PARAMETERS

Description

Overview of UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes

UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes)

Specifications of UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes

These UL/FM ASTM A53/795 SCH10 SCH40 pipelines are built for fire security. They fulfill strict UL and FM Global requirements. This authorization is crucial for fire lawn sprinkler. You need dependable pipelines when lives go to risk. These pipelines supply that dependability.

They are made from carbon steel. The steel is ERW bonded. This procedure makes solid, constant pipes. The pipes adhere to ASTM A53 and ASTM A795 requirements. These specs make sure top quality and efficiency. You obtain pipes in two timetables: SCH10 and SCH40. SCH10 has a thinner wall. SCH40 has a thicker, stronger wall surface. Select based on your system’s stress needs.

The pipe ends are grooved or slotted. Grooved ends permit quickly, strong connections using combinings. Slotted ends offer similar advantages. Both link kinds speed up setup. They make the job easier for your crew. The grooved or slotted ends await usage right away.

A vital function is the red epoxy layer. The shade is common RAL 3000 Signal Red. This bright red shade is easy to place. It immediately determines fire security lines. The epoxy finish is difficult. It shields the steel pipe from corrosion. The covering withstands damage throughout handling and setup. It helps the pipes last much longer inside buildings. The covering is smooth inside. This level of smoothness aids water circulation easily with the system.

These pipes are designed specifically for fire lawn sprinklers and standpipes. They deal with water stress successfully. Their UL/FM listing implies they are checked for fire safety. Using authorized elements keeps your building certified. These pipes offer a dependable remedy. They combine strength, appropriate certification, and simple installment. You obtain an item all set for vital fire security work.

(UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes)

Applications of UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes

These pipes protect buildings from fire. They are steel pipelines produced fire lawn sprinkler and various other fire defense makes use of. They fulfill stringent standards. UL and FM certifications mean they are authorized for fire safety and security. ASTM A53 and BS 1387-1985 criteria guarantee high quality product and building and construction.

The pipelines are available in common sizes. Set Up 10 (SCH10) is lighter weight for lower stress lines. Set Up 40 (SCH40) is thicker and deals with greater pressure. Both schedules are offered. They are made from carbon steel. The steel is created utilizing the Electric Resistance Welding (ERW) procedure. This produces a solid, reliable pipeline.

Completions are particularly prepared. Grooved ends allow rapid link making use of mechanical combinings. Slotted ends are likewise an alternative. This makes setup quicker and simpler at work site. You don’t require welding or threading tools.

The pipes have a safety coating. The exterior is coated in a challenging red epoxy paint. The details red color is RAL 3000. This intense shade helps recognize fire lines rapidly. The epoxy finish fights corrosion and deterioration. This security makes the pipes last much longer. It keeps the system reliable.

These pipelines operate in lots of fire defense systems. They are best for wet sprinkler systems carrying water. They are also made use of in completely dry pipe sprinkler systems that hold air or nitrogen. Standpipe systems for firefighter pipes utilize them as well. They link fire pumps and water tank. They form the major lines feeding water throughout a structure. Fire hydrant supply lines also utilize this pipe.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

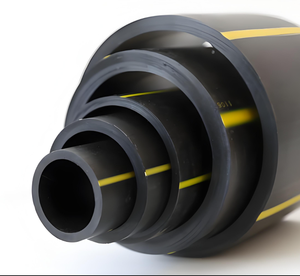

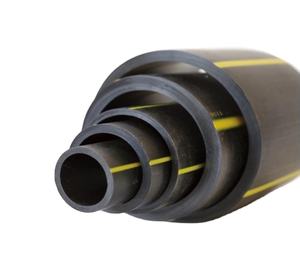

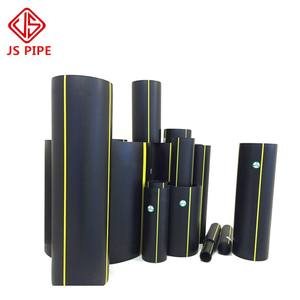

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes

These pipes are steel pipes for fire sprinklers. They carry water in fire protection systems. They meet UL and FM standards for safety. They also follow ASTM A53 and ASTM A795 rules. This means they are strong and reliable.

What are these pipes exactly? They are carbon steel pipes. They are made by ERW welding. This makes them durable. They come in two thicknesses: SCH10 and SCH40. SCH40 is thicker for higher pressure. Both have grooves or slots cut at the ends. This lets you connect them quickly with special couplings. They are always painted bright red. This is color RAL3000. Everyone recognizes this color means fire sprinkler pipe. They get a tough epoxy coating inside and out. This stops rust and corrosion. It helps the pipes last a long time.

Where are these pipes used? They are mainly for fire sprinkler systems inside buildings. You see them in offices, stores, factories, and warehouses. They connect to sprinkler heads. Water flows through them when a fire starts. The grooves make installation fast. This saves time and money on the job site.

Why are they always red? The bright red color is a safety rule. It is standard RAL3000 red. This color tells everyone the pipe is only for fire sprinklers. Workers know not to use it for anything else. It prevents mistakes. The red color is easy to spot in a building.

What does the epoxy coating do? The epoxy coating is very important. It covers the entire pipe inside and out. This coating protects the steel from water and moisture. It stops rust from forming. Rust can weaken pipes or block water flow. The epoxy layer makes the pipe last much longer. It keeps the system working well.

Why use grooved or slotted ends? Grooved ends are very practical. You fit a special coupling over the grooves. You tighten bolts. The connection is done. This is much faster than welding or threading pipes. It saves labor time. It also makes the system easier to change or fix later. Grooved connections are strong and hold pressure well. They are reliable for fire safety.

(UL FM ASTM A53/795 SCH10 SCH40 Grooved/Slotted End Red RAL3000 Epoxy Coating Carbon ERW Welded Fire Fighting Steel Pipes/Tubes)

REQUEST A QUOTE

RELATED PRODUCTS

Good ASTM A53 ERW Welded Steel Pipe Oil and Gas Pipeline Manufactured ERW Carbon Steel Line Pipe for Construction

Factory Directly Provide Thick Wall Seamless Pipes GB Large Diameter Carbon Steel Pipe

Stainless Steel Low Temperature Bellows DN40 Gas Liquid Pipe Liquid Oxygen Nitrogen LNG Metal Jacketed Hose Cryogenic Bellows

Factory Direct Standard Gb-t 18992 Lpg Gas Pipes Yellow Color 16-32mm Gas Pipe

All Specifications Huge Stock Underground Insulation Leakproof PE Yellow Gas Pipe for Gas

GOST 8732-78 Standard Hot-Deformed Carbon Steel Seamless Pipes for Oil and Gas

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677