LUOYANG DATANG ENERGY TECH CO.,LTD

Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe

PRODUCT PARAMETERS

Description

Overview of Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe

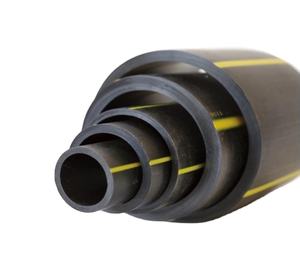

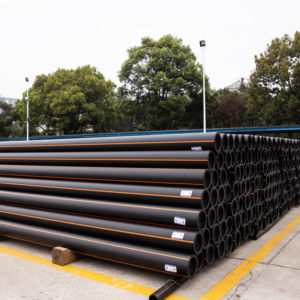

Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe)

Specifications of Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe

This carbon steel welded pipe begins with hot-rolled steel coil or plate. The product satisfies common criteria like ASTM A53 or API 5L. It offers good stamina and weldability. Manufacturers shape the steel into a cylinder. They weld the joint making use of high-frequency electrical currents or immersed arc welding. This creates a strong, permanent bond along the pipeline’s length.

The pipe can be found in several sizes. Outside diameters typically range from 1/2 inch as much as 24 inches or larger. Wall surface thickness differs substantially. Usual schedules include Schedule 40 and Arrange 80. Thicker walls manage greater pressure. Lengths are generally arbitrary or certain cut lengths. Usual random lengths fall between 18 and 22 feet.

The hot-rolling procedure gives the steel its first form. This affects the pipe’s final buildings. The pipeline has good mechanical stamina. It handles pressure well for lots of commercial usages. Surface coating is generally smooth. Mill range might be existing. This is the dark oxide layer developed during hot rolling. It can be left as-is or gotten rid of later.

Quality checks are very important. Factories do hydrostatic testing. This examination fills up the pipeline with water under high pressure. It look for leakages or weak points in the weld. Other examinations might consist of aesthetic evaluation and inspecting measurements. The pipeline must meet the demands of its specific quality requirement.

This welded pipe benefit relocating fluids and gases. Usual applications include water lines, architectural supports, fencing, and low-pressure heavy steam systems. It’s extensively available. It’s frequently a cost-effective option compared to seamless pipe for numerous basic applications. Purchasers need to verify the specific spec required for their project.

(Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe)

Applications of Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe

Carbon steel warm rolled weld pipe offers several crucial objectives across sectors. Contractors utilize it constantly in construction jobs. It develops solid frameworks for buildings and sustains for bridges. This pipeline handles hefty tons properly. Its resilience makes it ideal for demanding architectural applications.

The oil and gas market counts greatly on this pipe. It moves oil, natural gas, and other fluids over cross countries. Pipelines made from it crisscross countries. Its strength stands up to high stress underground or above ground. This is critical for safe power transport.

Water systems also depend on this pipe. Towns mount it to move drinking water to homes and companies. Wastewater therapy plants utilize it to bring sewage away. Its corrosion resistance, particularly with coverings, makes sure clean water distribution. Factories integrate it into plumbing for process water.

Industrial machinery often incorporates this pipe. It acts as protective channel for electric circuitry. It creates sturdy handrails and security barriers on. Manufacturers use it for frameworks on tools and storage shelfs. Its affordability and formability fit these diverse roles.

The vehicle and shipbuilding sectors utilize it too. It appears in car framework elements and ship structural elements. Its regular quality and weldability are key advantages below. Producers worth how quickly they can cut and join it.

This pipeline works well sought after settings. It performs reliably under high temperatures and pressures usual in power plants or chemical facilities. Its toughness ensures security in potentially harmful circumstances. This reliability makes it a default option for lots of designers.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe

What exactly is carbon steel hot rolled weld pipe? This pipe starts as steel strips called skelp. Manufacturers heat the skelp. They roll it into a cylinder shape. Then they weld the seam along its length. The hot rolling process makes the steel easier to form. It also improves the pipe’s strength.

Where is this pipe typically used? It handles many industrial jobs. You see it a lot in structural applications. Buildings and bridges use it. It works well for fencing and handrails. It transports water, oil, and gas. It serves in general fabrication too. Its strength and cost make it popular.

What are the main advantages? This pipe offers good strength. It is relatively affordable. It comes in many standard sizes. Hot rolling provides a consistent wall thickness. The weld is strong and reliable. It handles pressure well. It resists wear decently.

What sizes are available? Sizes vary a lot. Common outside diameters range from 1/2 inch to 24 inches. Wall thickness also varies. Thinner walls suit low pressure. Thicker walls handle higher pressure. Lengths are usually around 20 feet. Custom sizes are possible too.

Which standards apply? ASTM A53 Grade B is common. This standard covers welded pipe. It ensures the steel quality. It ensures the weld integrity. It ensures the dimensions are correct. Other standards exist for specific uses. Check the project requirements.

(Weld Steel Pipe Carbon Steel Hot Rolled Weld Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

1/4″ Cast Technics Flexible Carbon Steel Gas Pipe

Competitive s Astm A106 Grade B Hot Rolled Steel Tube Carbon Seamless Steel Pipe Welded Steel Pipes

ASTM A106 A53 Seamless Steel Pipe Gr. B API 5CT OCTG Carbon Steel Casing Pipe / Oil / Gas Using Pipe

6mm 16mm Wall Thickness Octg Grdae K55 N80 L80 Carbon Seamless Steel Pipe

Q195 Q215 Q235 Q255 Q275 Q345 20#10# Carbon Steel Pipe ASTM Factory Direct Supply for Oil and Gas Carbon Steel Pipe

304 STAINLESS STEEL FLEXIBLE GAS PIPE, SS CORRUGATED GAS HOSE Flex Gas Connectors

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677