LUOYANG DATANG ENERGY TECH CO.,LTD

Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction

PRODUCT PARAMETERS

Description

Overview of Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction

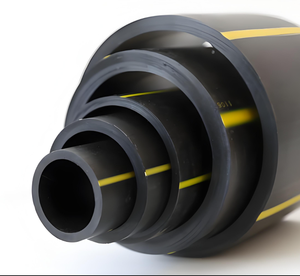

Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction)

Specifications of Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction

This bonded steel pipe satisfies ASTM A53 Grade B requirements. It’s made using the Electric Resistance Welding (ERW) process. This procedure utilizes electric current to heat and fuse the steel edges. It produces a solid, consistent weld joint. The pipeline dimension complies with Set up 40. This timetable specifies the wall density about the pipe diameter. Set up 40 provides a great balance. It provides strength without extreme weight or product use.

The material is carbon steel. Carbon steel is known for its strength and toughness. Quality B defines a minimum return toughness of 35,000 psi. It also sets demands for tensile stamina and chemical make-up. This makes certain reputable efficiency under stress. These pipelines take care of both fluid and gas transport properly. They are a main option for oil and gas gathering lines. They are additionally used for circulation pipelines. Their toughness makes them suitable for many building applications. Architectural uses and loading are common instances.

These pipelines are available in conventional dimensions. Typical outside diameters range from 1/8 inch approximately 26 inches or larger. Lengths are normally arbitrary double random (RDR), around 18-25 feet. They can also be cut to details sizes. The pipes have an ordinary end (PE) surface. This implies the ends are cut square. They are ready for threading or welding onto various other components. Surface finish is usually a light oil to prevent corrosion during storage. Black or bare finishes are also common.

The pipelines offer outstanding sturdiness. They stand up to inner stress well. They handle outside tons found in hidden pipelines. They also endure typical construction stress and anxieties. Their carbon steel structure gives great weldability. This makes signing up with areas uncomplicated throughout installation. ERW manufacturing maintains costs competitive. This makes ASTM A53 Gr. B Schedule 40 ERW pipe an economical solution. It provides necessary efficiency for demanding oil, gas, and construction projects.

(Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction)

Applications of Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction

Welded steel pipelines ASTM A53 Gr. B ERW Schedule 40 are essential for relocating oil and gas. Their strength and integrity make them best for pipelines. These pipelines deal with the high pressure needed to transfer oil and gas securely over cross countries. The Schedule 40 wall surface thickness provides this stress resistance. The pipelines are made from carbon steel. This material uses excellent stamina and toughness. The ERW method (Electric Resistance Welding) produces a strong, regular joint. This seam is essential for pipeline safety and security. The ASTM A53 Gr. B standard makes sure the pipelines satisfy rigorous top quality requirements. This consists of chemical make-up and mechanical residential properties. Making use of certified pipes like ASTM A53 Gr. B is vital for pipeline integrity. It prevents leakages and failures. These pipes withstand deterioration efficiently. This is necessary for underground or undersea pipes. Appropriate coatings add added defense. Lengthy life span reduces substitute expenses.

These pipes are additionally widely made use of in building construction. Their strength supports frameworks. Home builders use them for structural columns and frameworks. They lug hefty tons reliably. The Set up 40 density gives excellent stability. It avoids giving in stress. The round form is simple to work with. Professionals connect them utilizing conventional approaches like welding or threading. This quickens building tasks. They prevail in commercial buildings and storage facilities. They develop the skeletal system of large structures. Their durability makes sure the structure lasts a very long time. They endure weather and stress and anxiety well. Upkeep requirements are low. This saves cash in time. The ASTM A53 Gr. B certification gives building contractors confidence. They recognize the material fulfills construction requirements. These pipes are a practical choice for several structural needs. They supply a strong balance of performance and cost.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction

What are ASTM A53 Gr. B ERW Schedule 40 pipes?

These are carbon steel pipes. They are made by the ERW process. ERW means Electric Resistance Welding. Steel strips are formed into a cylinder. The edges are heated and pressed together to form a strong seam. Schedule 40 refers to the wall thickness. This thickness makes them strong and durable. They are commonly used for moving fluids and gases under pressure.

What material are they?

They are made from carbon steel. The specific grade is ASTM A53 Grade B. This grade is known for its strength. It has good yield and tensile strength. Carbon steel is tough and reliable. It handles pressure well. This makes it suitable for demanding jobs.

Where are these pipes used?

Their main uses are oil and gas pipelines. They carry oil and gas over long distances. They are also used in construction. Examples include structural supports and piling. They are good for fencing and scaffolding too. They work well for water lines and general plumbing. They handle both high pressure and structural loads.

Why choose ERW Schedule 40 pipes?

They offer a good balance of strength and cost. The ERW process is efficient. This makes the pipes affordable. Schedule 40 walls are thick enough for many pressure jobs. It bends less than thinner pipes. They are strong for their weight. They are easy to weld and install. They last long. This is good for budgets and projects.

What standards do they meet?

These pipes meet the ASTM A53 standard. This standard covers seamless and welded steel pipe. Grade B is the common grade for welded pipe. The standard ensures the pipes are safe and reliable. It controls the chemical makeup. It controls the mechanical properties. It controls the testing methods. Pipes meeting ASTM A53 Gr. B are trusted for critical jobs.

(Welded Steel Pipes ASTM A53 Gr. B ERW Schedule 40 Carbon Steel Pipe Used for Oil Gas Pipeline and Construction)

REQUEST A QUOTE

RELATED PRODUCTS

Seamless Steel/oil Gas Casing Drill Pipe Carbon Steel Seamless Pipe

API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

Seamless Weld Tube ASTM A106 A36 A53 A192 Q235 Carbon Steel Pipe

Low ASTM Hot Rolled Carbon Seamless Steel Pipe 20# 45# Seamless Steel Tube

API 5L Gas Pipe Carbon Seamless Steel Tube 20G

Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677